3d print zits & blobs: 6 tips to prevent them

Have you ever attempted a 3D print and been disappointed with the final product due to unwanted blobs or zits? It’s frustrating, especially when you’ve spent hours designing and printing your creation. But fear not, there are several ways to prevent these imperfections from ruining your print.

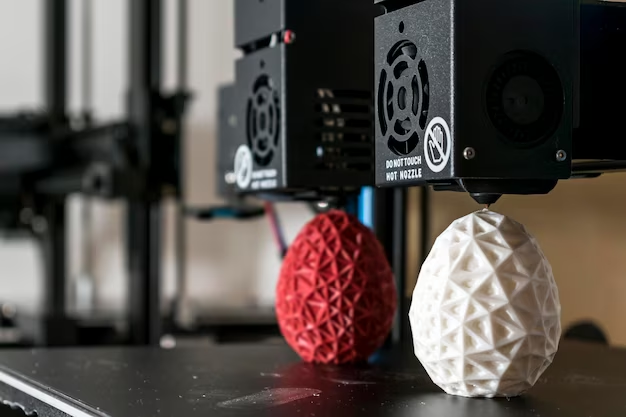

1. Keep your nozzle clean – Make sure you regularly perform maintenance on your printer’s nozzle to keep it free of dirt, dust, or other particles that may cause zits or blobs during printing.

2. Adjust extrusion temperature – If the plastic being extruded is too cold or hot it can create bumps and deformations in the print which will result in zits & blobs. Adjusting the temperature correctly can help reduce these issues.

3. Use quality filament – Cheap filaments tend to be inconsistent in diameter which can cause issues with feeding and lead to accumulations of plastic that form bumps on the surface of a print. Investing in quality filaments will help aid in smoother prints.

4. Choose correct flow rate – The flow rate should match the layer height you’re printing at; if it’s set too low it won’t feed enough material leading to gaps and defects like zits & blobs forming on the model’s surface .

5. Check fan speed – Make sure your fan speed is adjusted according to what type of material you’re using as some materials need more cooling than others; incorrect cooling speeds can also cause problems with plastic accumulations leading to zits & blobs .

6. Monitor retraction settings – When purchasing a new 3D printer, there are a few important considerations to keep in mind.

The first is cost – how much can you afford to spend on your 3D printer? It’s important to figure out a budget before doing any shopping around. Additionally, it is essential to consider the size and build area of the 3D printer. If you plan on printing larger objects, you will need a machine with adequate build space.

The Causes

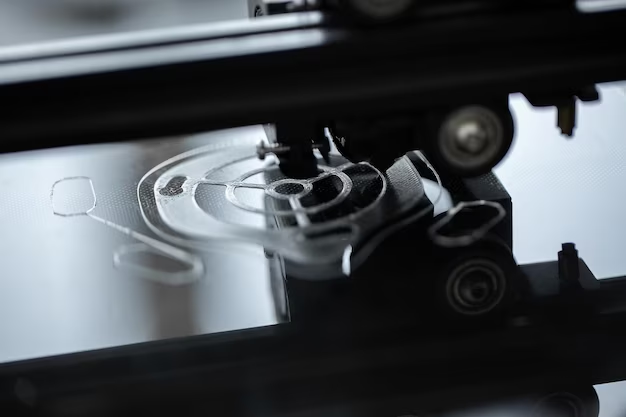

The causes of zits and blobs on 3D prints can vary, but some of the most common ones are over-extrusion, improper bed leveling, nozzle clogging, and incorrect temperatures. Over-extrusion is when too much plastic is forced through the nozzle at once during extrusion and this can cause excess material to build up in certain areas leading to zits or blobs.

Improper bed leveling can also lead to these issues because it can create uneven pressure across the printing surface which leads to inconsistent extrusion. Nozzle clogging is another common cause as a clogged nozzle will limit the amount of filament that passes through and can result in incomplete parts.

The first and most important step in preventing zits and blobs on your 3D prints is to ensure that the extrusion is correct. This means that you need to tune your printer’s extruder so that it can accurately measure how much filament should be pushed through.

Calibrating the extruder involves ensuring that the steps per mm for each axis is accurate, as well as making sure the tension of the filament being fed into the hot end is just right. Additionally, you might want to check that your flow, or extrusion multiplier in your slicer profile is set correctly – this setting allows you to control how much filament your printer will be told to extrude during a print job.

Tip #2: Lower Temperature & Speed

Tip #2: Lower Temperature & Speed

In order to reduce the likelihood of zits and blobs forming on your 3D prints, it is important to lower both your nozzle temperature and print speed. By lowering the nozzle temperature by 5-10 °C and the printing speed by 5-10 mm/s, you can ensure that there is enough time for each layer of material to cool and settle before the next layer is added.

This will help reduce over-extrusion which can cause zits and blobs to form. You may also want to consider reducing your extrusion width as this can also help with unwanted zits or blobs forming on your prints. Additionally, make sure that you are using a quality filament as this can also play a role in preventing these imperfections from occurring.

Tip #3: Adjust Retraction

Retraction plays a critical role in preventing zits and blobs from forming on 3D prints. By adjusting the retraction settings in your 3D slicer profile, you can help reduce the amount of plastic that is unintentionally extruded due to pressure build-up in the hot end.

When adjusting your retraction settings, make sure that you consider the frequency, distance, and speed of retraction. A higher frequency may be needed for small details or complex geometry whereas a lower frequency may be better for larger features. Additionally, it is important to ensure that the distance and speed of retraction are set to optimal levels so as not to cause any damage to the printhead or nozzle.

Retraction Minimum Travel

Retraction Minimum Travel is an important setting to consider when 3D printing. This setting determines the minimum distance the nozzle must travel before a retraction action can be initiated, and helps prevent zits and blobs on your prints. When this value is set too low, it can cause too many retractions and create more problems than it solves.

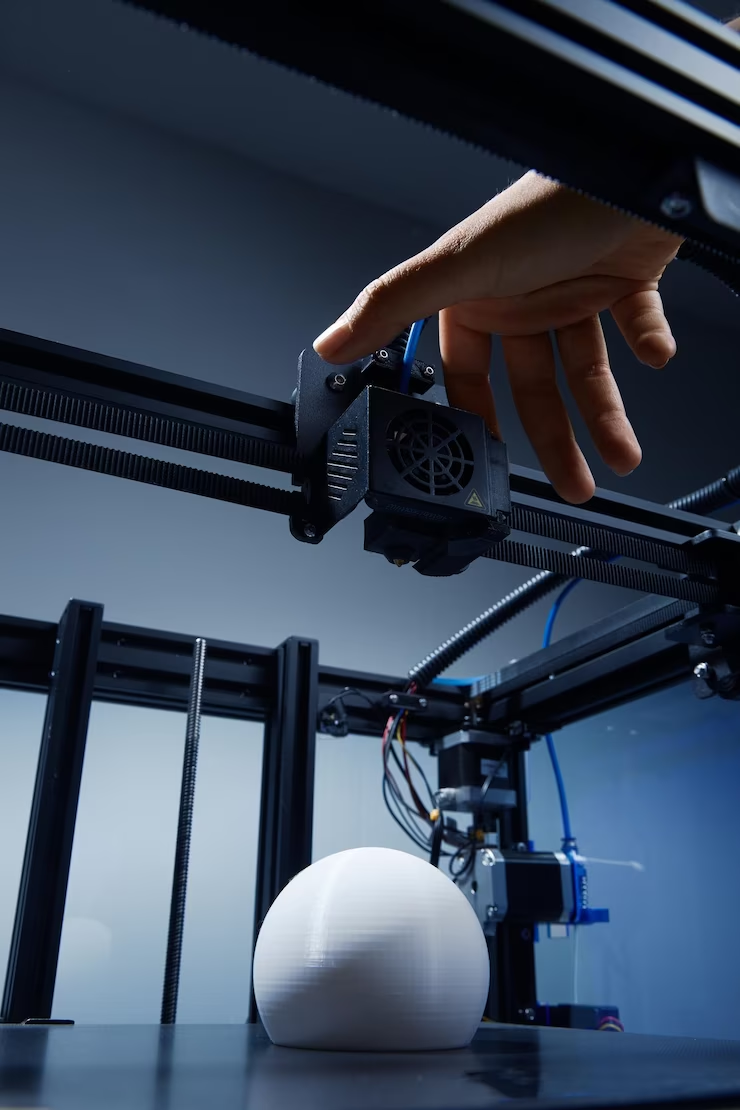

On the other hand, when it is set too high, it can increase the risk of pressure build-up in the hot end which could lead to extrusion issues. It’s best to find a balance that works for your printer model and materials being used. Additionally, you should adjust Z hop settings if necessary so that the printhead does not touch any part of the design during retraction.

Retraction Distance

Retraction Distance is a crucial setting to consider when 3D printing. This setting determines how much filament is pulled back for every retraction event, and can significantly affect the quality of your prints. If the retraction distance is too small, not enough filament will be sucked back from the hot end, resulting in blobs and zits on your print.

On the other hand, if retractions are too large, there will be a gap between the end of the filament and the nozzle which can cause bubbles or blobs on a print. To find an ideal balance, it is best to start with increasing retraction distance and then lowering it if that doesn’t reduce problems. Additionally, you should adjust Z hop settings so that the printhead does not touch any part of the design during retraction.

Retraction Speed

Retraction speed is another important setting to consider when 3D printing. This setting determines how fast the filament is pulled back during a retraction, and can have a huge impact on the quality of your prints. Too slow of a retraction speed won’t effectively pull the filament away from the nozzle, resulting in blobs and zits on your print. To prevent this from happening, it’s best to increase the retraction speed by around 25%, with an upper limit of 65 mm/s. You should also check that you have enough retractions enabled for parts with complex geometries as well as adjust Z hop settings so that the printhead does not touch any part of the design during retraction. By tuning these settings properly you should be able to reduce or eliminate blobs and zits from forming on your prints.

Tip #4: Increase Cooling

Increasing the cooling of your 3D printer is an important step to take in order to prevent blobs and zits from forming on your prints. By increasing the speed of your cooling fan, you can ensure that a part cools faster and more evenly, reducing the chances of zits and blobs forming.

To do this, increase the fan speed in your slicer by increments of 10% until you have reached a suitable level for preventing zits and blobs. If your fan cannot be set high enough, you can also add additional fans or replace it with a more powerful one. Additionally, lowering the nozzle temperature will also help reduce over-extrusion and the formation of zits and blobs.

Tip #5: Use Coasting

Coasting is a useful tool for helping to reduce the formation of zits and blobs on 3D printed parts. Coasting involves telling your printer to stop extruding material a small distance before a print move ends, as this helps to predict hot end pressure and use it to prevent over-extrusion.

This can be done by activating coasting in your 3D slicer program and adjusting it accordingly based on its effectiveness. To do this, you need to adjust the coasting parameters in your slicer settings until you find the right balance that works best for your printer.

Tip #6: Adjust Shell Settings

Shell settings are a great way to prevent zits and blobs from appearing on your 3D prints. By adjusting the wall thickness, top/bottom layers, and other shell options in your slicer program, you can control how many shells are printed around the outside of your objects. The thicker the shell walls, the more likely they are to hide any minor blemishes that might appear on the surface of your object due to inconsistent extrusions or other factors.