How much does metal 3d printing cost?

Have you ever heard of metal 3D printing? It’s a rapidly growing technology that has revolutionized the manufacturing industry. But what exactly is it?

3D printing has been around for a few decades, but it’s only in recent years that metal 3D printing has gained popularity. This process involves using a 3D printer to create objects out of metal powder, layer by layer.

Metal 3D printing has opened up a world of possibilities for designers and engineers. It allows for complex shapes and designs that would be impossible with traditional manufacturing methods. In this article, we’ll dive deeper into what metal 3D printing is, how it works, and the benefits and limitations of this cutting-edge technology.

Metal 3D printing is quickly becoming a popular choice for manufacturing due to its accuracy, speed, and ability to produce complex designs. However, one question that arises is how much does it cost to 3D print metal?

Metal 3D printing has been around for a while, but it is only recently that it has become more accessible and affordable. With advancements in technology, the cost of metal 3D printing has decreased, making it a viable option for both small and large businesses.

The cost of metal 3D printing depends on various factors, including the type of metal, the size and complexity of the design, and the printing technology used. In this article, we will explore the cost of metal 3D printing and provide you with a breakdown of the factors that contribute to the final price. Whether you are a business owner or a hobbyist, understanding the cost of metal 3D printing can help you make informed decisions about your next project.

How much does metal 3d printing cost?

The cost of metal 3D printing can vary greatly depending on the type and complexity of the project. Generally, larger and more complex prints tend to be more expensive than smaller, simpler prints. Additionally, the type of metal being printed affects the final cost.

For example, stainless steel and titanium are typically more expensive than aluminum or bronze due to their higher melting points. The cost of printing also depends on the method and technology used for 3D printing.

On average, metal 3D printing can cost anywhere from $2-$10 per cubic inch of material used. However, this amount can vary widely depending on the project and type of metal used. For more information on pricing, it is best to contact a local 3D printing service provider for an accurate quote.

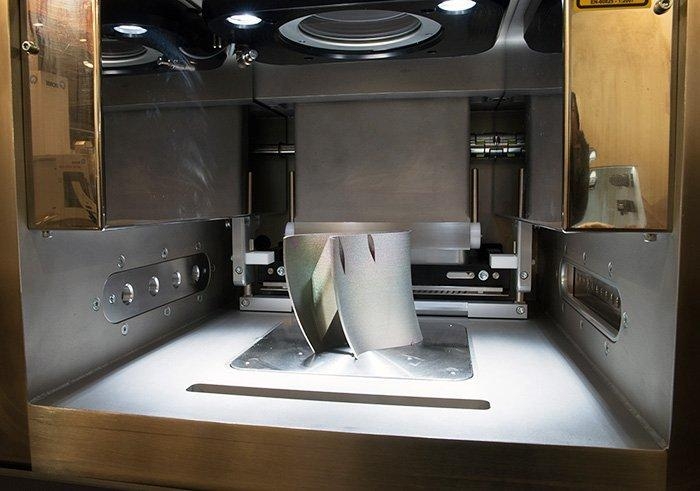

When it comes to the actual process of metal 3D printing, there are several steps involved. First, the design is created using Computer Aided Design (CAD) software and then converted into a STL file format for printing. Next, the metal powder is spread evenly on the printing bed before being melted layer by layer using a laser or electron beam. Once completed, the print must be post-processed to remove any excess material and achieve a polished, smooth finish.

Overall, metal 3D printing offers many benefits over traditional manufacturing methods. It is cost-effective, can produce complex designs with intricate details, and has a much shorter lead time when compared to traditional methods. However, the technology is still in its early stages and certain limitations remain in terms of size and materials available.

Ultimately, the cost of metal 3D printing varies depending on a wide range of factors. It is important to have a clear understanding of the project requirements and budget before deciding on a particular process or technology. By doing so, you can ensure that you receive the most cost-effective solution for your project’s needs.

Metal 3D printing is a great way to quickly create complex parts and prototypes that would be difficult or impossible with traditional manufacturing methods. It also offers greater accuracy, speed, and cost savings when compared to other processes.

However, before deciding on a particular technology or process, it’s important to consider additional factors such as the size of the part, the complexity of the design, and the type of metal used. By understanding all of these aspects, you can ensure that the final product meets your expectations and budget.

Is 3D printing metal expensive?

Is 3D printing metal expensive? The cost of metal 3D printing can vary greatly depending on the type and complexity of the project. Generally, larger and more complex prints tend to be more expensive than smaller, simpler prints. Additionally, the type of metal being printed affects the final cost. On average, metal 3D printing can cost anywhere from $2-$10 per cubic inch of material used. It is important to contact a local 3D printing service provider for an accurate quote.

Metal 3D printing offers a variety of benefits over traditional manufacturing techniques. It allows for increased customization, shorter lead times, and greater accuracy when creating complex shapes and designs. Additionally, metal 3D printing is generally more cost-effective than conventional methods since it eliminates the need for additional tooling or molding costs. Despite this, it is important to remember that prices can vary depending on the type and complexity of the project. Ultimately, it is important to consider all factors before deciding on a particular process or technology.

When it comes to metal 3D printing, an important factor to consider is the type of material being printed. While some materials like stainless steel or titanium may require post-processing to achieve a smooth finish, certain metals such as aluminum are much easier to work with and are generally more cost-effective. Additionally, some metals may be better suited for particular projects than others; this should be taken into account when looking for a cost-effective solution.

In conclusion, the cost of metal 3D printing can vary greatly depending on the size and complexity of the design as well as the type of material used. Generally, larger and more complex prints tend to be more expensive than smaller and simpler prints. Additionally, certain metals like stainless steel or titanium may require post-processing to achieve a smooth finish and can be more costly than others. Ultimately, it is important to consider all of these factors before deciding on a particular technology or process.

Metal 3D printing is also a great way to quickly create intricate parts and designs that would not be feasible with traditional methods. It provides a high level of accuracy, speed, and cost savings compared to other manufacturing processes.

What is the cheapest way to 3D print metal?

The cheapest way to 3D print metal is to use selective laser sintering (SLS) technology for smaller prints. This process involves using a laser to fuse together powdered metal, creating three-dimensional shapes without the need for additional tooling or molding costs.

For larger prints, powder bed fusion (PBF) is typically more cost-effective. Additionally, certain metals such as aluminum are generally more cost-effective than others. It is important to contact a 3D printing service provider for an accurate quote before starting any project.

When it comes to metal 3D printing, the cost of material is a major factor to consider. Aluminum is typically the most economical metal for 3D printing, although other metals like stainless steel or titanium can be more expensive. Additionally, certain post-processing techniques such as polishing may be necessary to achieve a smooth finish with certain materials, which could add additional costs to the project.

Metal 3D printing is also a great way to quickly create intricate parts and designs that would not be feasible with traditional methods. It provides a high degree of accuracy, speed, and cost savings compared to other manufacturing processes. Additionally, metal 3D printing makes it easier to produce customized products, as the entire process can be adjusted on the fly.