Do you need a slicer to 3d print?

Have you ever wondered whether you really need a slicer to 3D print? Maybe you’ve heard conflicting information about whether slicers are necessary or not. The truth is, it depends on what you’re trying to accomplish with your 3D prints.

A slicer is a software program that takes a 3D model and slices it into thin layers, generating a file that a 3D printer can read and use to print the model. Some argue that a slicer is necessary to get the best results from your 3D prints, while others claim that it’s not necessary at all.

Before you decide whether or not to use a slicer in your 3D printing projects, it’s important to understand what it does and how it can affect your prints. In this article, we’ll explore the benefits and drawbacks of using a slicer to help you make an informed decision about whether you need one or not.

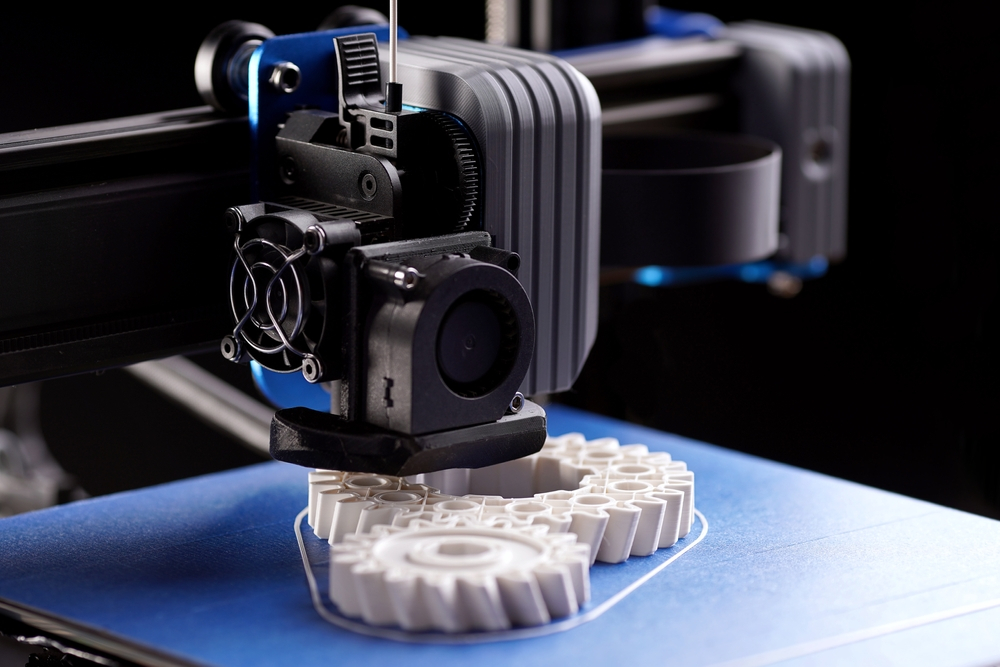

What is 3D Printing?

3D printing is a process of creating three-dimensional objects from digital designs. It is done with the help of a 3D printer, which uses a layer-by-layer approach to create objects as big or small as you want. The process starts by loading a 3D file into the 3D printer and then selecting the right materials for the job.

Once that’s done, the printer will begin to heat up and deposit layers of molten plastic onto each other until it creates an object according to your design. Depending on the complexity and size of your object, this could take anywhere from minutes to hours. After your object has finished printing, it can be sanded down, painted or post-processed in whatever way you’d like to achieve the desired result.

What is a Slicer?

A slicer is a type of software used in 3D printing. It takes a 3D model and slices it into layers that can be printed by the 3D printer. Each layer contains instructions for the printer to create the finished product, and the slicer is responsible for converting the model into these individual layers. The slicing process usually involves adjusting settings such as fill pattern, wall thickness, infill density and print speed.

By making the right adjustments, you can ensure that your prints will come out with a good quality finish. Slicers are an essential tool for anyone who wants to get the most out of their 3D printing experience, as they provide a way to optimize your prints for quality and performance.

Do You Need a Slicer to 3D Print?

Do you need a slicer to 3D print? The answer is yes. A slicer is a type of software used in 3D printing that takes a 3D model and slices it into layers that can be printed by the printer. It’s responsible for converting the model into individual layers, which are then used to create the finished product.

Slicers also allow you to adjust settings such as fill pattern, wall thickness, infill density and print speed, ensuring that your prints come out with a good quality finish. Without a slicer, 3D printing would be much more difficult and less efficient. If you want to get the most out of your 3D printing experience, it’s essential that you use a slicer. By doing so, you’ll be able to optimize your prints for quality and performance.

Types of Slicers

There are several different types of slicers available on the market today. The two main categories are open source and proprietary slicers. Open source slicers are free to use, while proprietary slicers require a license to use them. Open source slicers tend to be more customizable than proprietary ones and may offer features such as automatic support generation and multiple extruders for multi-material prints.

Proprietary slicers typically have better user interfaces and offer more advanced features such as pre-defined print profiles, which can save you time when setting up your prints. Both types of slicers have their own advantages and disadvantages, so it’s important to choose one that best suits your needs.

Open Source Software

Open source software is computer software that is released under a license in which the copyright holder grants users the right to use, study, modify, and distribute the software. Open source software is often developed collaboratively by volunteers who donate their time and expertise. This type of software has become increasingly popular in recent years due to its cost-effectiveness, transparency, and quality assurance.

Open source slicers are an especially great choice for 3D printing hobbyists as they typically offer more customization than proprietary slicers. They also provide access to a large community of users who can help answer questions or provide tips and tricks on how to get the most out of your 3D printer. As with any type of software, it’s important to evaluate your options carefully before selecting a slicer. However, open source slicers can provide a great way to save money while still providing powerful features for 3D printing.

Proprietary Software

Proprietary software is computer software that is owned by a specific entity or individual and is not publicly available. It includes commercial off-the-shelf (COTS) software, developed in-house by a company or organization, and proprietary operating systems like Windows. Proprietary software typically restricts users to certain terms of license, and copyright holders may limit how the software can be used, modified, and distributed. For 3D printing hobbyists, proprietary slicers can offer more streamlined user experiences than open source ones due to their limited customization options.

They also often come with higher price tags than open source slicers but may be worth it for those who need specialized features that aren’t available in open source programs. Additionally, many proprietary slicers have access to larger support networks where users can quickly find answers to their questions or receive technical assistance from the manufacturer’s customer service team.

Online Tools and Services

Online tools and services have become invaluable in the 3D printing community. These digital tools provide users with the ability to quickly create and modify designs, troubleshoot prints, and even collaborate with others on projects. From free modeling software that can be used to craft a 3D image from scratch, to paid cloud-based services that allow users to remote monitor a print’s progress or share files across different platforms, there are plenty of options for those looking for versatile tools to streamline their workflow.

For hobbyists who want the convenience of online services without the added expense, many open source programs can provide similar features as those found in more costly proprietary versions. Regardless of budget or experience level, anyone using 3D printing technology stands to benefit from these modern advances.

Mobile Apps for 3D Printing

Mobile apps have become a must-have tool for 3D printing enthusiasts, providing users with the ability to manage their projects on-the-go. From viewing and sharing 3D models to monitoring a print in real time, these apps offer unprecedented convenience. Popular software like Cura and Simplify3D make it easy for users to adjust settings and troubleshoot prints from any location.

Additionally, many manufacturers provide dedicated mobile apps that are tailored to specific machines. By connecting directly to the printer, users can monitor progress remotely or even start a print from anywhere with an internet connection. With more sophisticated features being added each day, mobile apps are quickly becoming an essential component of any 3D printing setup.

Benefits of Using a Slicer

Using a slicer is one of the most important steps in 3D printing. A slicer is software that takes your 3D model and converts it into instructions for the printer to follow. This process, known as “slicing,” allows users to adjust a variety of settings and ensure that the print will turn out exactly as expected. For beginners, using a slicer can seem daunting at first, but there are many advantages to mastering this essential skill.

The main benefit of slicing is that it allows you to preview a 3D model layer-by-layer before it’s printed, so you can easily identify any potential errors or make adjustments if needed. Additionally, by tweaking settings such as infill percentage, support structures and travel speed, users can optimize the print for time or quality. With a proper setup, prints will be faster and more reliable than ever before.

Furthermore, some slicers come equipped with features like automatic bed leveling and filament monitoring which can further streamline the process. In short, learning how to use a slicer properly is an invaluable skill for any 3D printing enthusiast. It not only ensures successful prints but also makes the entire process much easier and more enjoyable overall.

Improved Print Quality & Speed

Using a slicer is one of the best ways to ensure that your 3D prints turn out exactly as expected and with minimal fuss. Slicers allow users to preview a 3D model layer-by-layer, so any errors can be spotted before they become an issue. Additionally, by adjusting settings such as infill percentage, support structures and travel speed, users can optimize the print for time or quality.

In doing so, prints will be faster and more reliable than ever before. Furthermore, some slicers come equipped with features like automatic bed leveling and filament monitoring which can further streamline the process. Ultimately, learning how to use a slicer properly is essential for anyone looking to get the most out of their 3D printer. By taking full advantage of these tools and features, you’ll be able to enjoy improved print quality and speed in no time!