How thin can 3d printers print?

Three-dimensional (3D) printers are becoming increasingly popular, allowing for the creation of complex objects with intricate details. But how small can these printers actually go? Can they produce objects with incredibly delicate and thin details?

The use of 3D printing has expanded beyond just a hobbyist’s pastime, with industries like medical and aerospace utilizing the technology for various applications. However, the size limitations of 3D printing have always been a topic of discussion.

As the demand for smaller and more intricate objects continues to increase, it’s important to understand the capabilities of 3D printers. How thin can they print and what factors might limit their ability to do so? In this article, we delve into the world of 3D printing and explore the limits of how thinly it can print.

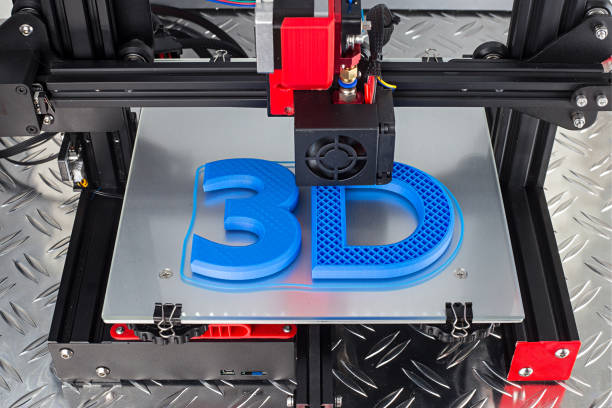

What is 3D Printing?

3D printing is a process of creating three-dimensional solid objects from a digital file. It works by laying down successive layers of material until the desired object is created. The technology has been used for decades in industry, but its adoption in consumer markets has grown exponentially in recent years.

3D printers are now available at an affordable price, and they can be used to create prototypes, medical implants, jewellery and even food. 3D printing offers certain advantages over traditional manufacturing methods such as faster production times and reduced costs. Additionally, it allows product designers to quickly test out ideas with minimal investment.

While there are still some limitations to what can be printed, 3D printers can print extremely thin layers of material – as thin as 0.1mm depending on the printer model – making them suitable for intricate designs that would otherwise be impossible to produce using traditional methods.

What Can 3D Printers Print?

3D printing is a rapidly growing technology that is becoming increasingly accessible and affordable. It has revolutionized the way products are designed, prototyped and manufactured. 3D printers can print a wide range of materials such as plastic, metal, glass and even food.

The thin layers of material they are capable of producing can be as thin as 0.1mm depending on the printer model. This allows for detailed prints with intricate designs that would otherwise be impossible to produce using traditional methods.

3D printers can create items such as medical implants, jewellery, toys and prototypes quickly and cost-effectively. As technology continues to progress in this field, the possibilities for what can be created with 3D printers will continue to grow exponentially – making them an invaluable tool for product designers and makers alike.

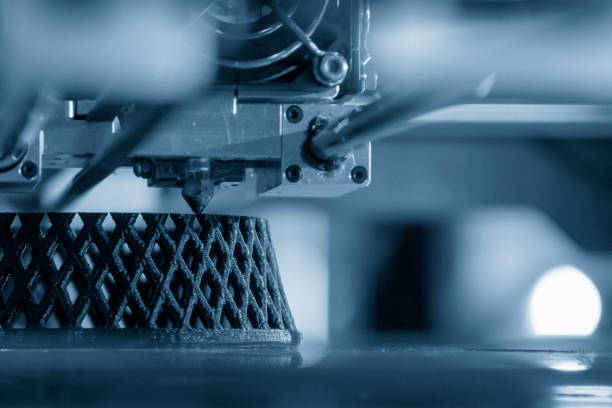

Types of 3D Printer and Nozzle Sizes

3D printers are becoming an indispensable tool for product designers, makers and innovators. There are various types of 3D printers that come with different nozzle sizes. Fused deposition modeling (FDM) is the most common type of 3D printer, which uses a heated nozzle to extrude melted plastic onto a build plate in layers.

The nozzle size will determine the minimum layer height achievable with this type of printer; the smaller the nozzle, the thinner the layers it can produce. A standard 0.4mm nozzle can lay down layers as thin as 0.1mm, while larger nozzles such as 0.8mm or 1.2mm are better suited for faster printing but have a minimum layer thickness of 0.2mm and 0.3mm respectively.

Other types of 3D printers include stereolithography (SLA), selective laser sintering (SLS) and digital light processing (DLP). Each one has its own advantages and disadvantages depending on what you are trying to create, so it’s important to choose the right one for your project.

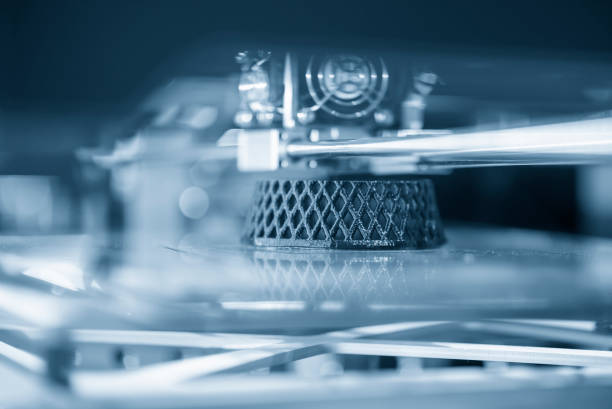

Fused Deposition Modeling (FDM) Printers

Fused Deposition Modeling (FDM) printers are some of the most popular 3D printing technologies available today. This type of printer utilizes a heated nozzle to melt and extrude plastic filaments onto a build plate in layers. FDM printers can produce parts with high accuracy and detail, making them a great choice for prototyping and product development. They are also relatively affordable compared to other types of 3D printers.

Depending on the nozzle size chosen, FDM printers can produce layers as thin as 0.1mm, allowing for intricate designs that would be impossible with other methods. FDM technology is versatile and easy to use, making it an ideal choice for many applications such as rapid prototyping, functional testing, small-scale production runs, and more.

Selective Laser Sintering (SLS) Printers

Selective Laser Sintering (SLS) printers use a laser to fuse small particles of plastic, metal, ceramic, or glass powder into a 3D object. This technology is capable of producing parts with intricate details and high accuracy. It is also highly versatile, allowing users to create complex models with different materials including hard plastics and metals such as stainless steel.

The layer thickness for SLS printing can be as thin as 0.05mm, making it ideal for applications that require intricate detail or thin walls. These printers are relatively expensive compared to other types of 3D printers but offer several advantages such as high dimensional accuracy and good surface finish. SLS is used in industries such as automotive, consumer goods, medical device manufacturing, and more.

Stereolithography (SLA) Printer

Stereolithography (SLA) Printers are among the most common 3D printing technologies. It works by using a UV laser to selectively cure liquid resin into a solid object layer by layer. This technology is known for its high accuracy, surface finish, and detail resolution. SLA printers can produce parts with layers as thin as 0.025mm – making them ideal for applications that require very fine details or thin walls. These printers are typically used in industries such as dental, jewelry, and medical device manufacturing due to their ability to produce complex and detailed components quickly. Additionally, SLA printers work with a wide range of materials including photopolymers, waxes, elastomers, and more.

How thin can 3d printers print

1. It depends on the printer and the material being used. Most consumer-grade 3D printers can print layers that are as thin as 0.1 millimeters. However, some high-end industrial printers can print layers as thin as 0.01 millimeters (10 microns).

2. The thinner the layer, the higher the resolution of the object being printed. A thinner layer means that the printer can create more intricate details and smaller features.

3. The size of the printer’s nozzle can also affect how thin it can print. Nozzles with a smaller diameter can print thinner layers, while larger nozzles are better suited for printing larger objects.

4. The type of material being used also plays a role in how thin it can be printed. Some materials are too viscous or too brittle to be printed at very thin layers.

5. The printing speed can also affect how thin the printer can print. Slower printing speeds allow for thinner layers to be printed, while faster speeds may require thicker layers to maintain structural integrity.

6. Post-processing techniques, such as sanding or polishing, can help to smooth out any rough edges or inconsistencies in the printed object, allowing for even greater precision.

7. Overall, the thinnest possible layers that can be printed by a 3D printer are limited by the precision and capabilities of the printer technology, as well as the properties of the materials being used. As technology advances, we can expect to see even thinner layers being printed with greater precision and quality.