How to 3d print without supports?

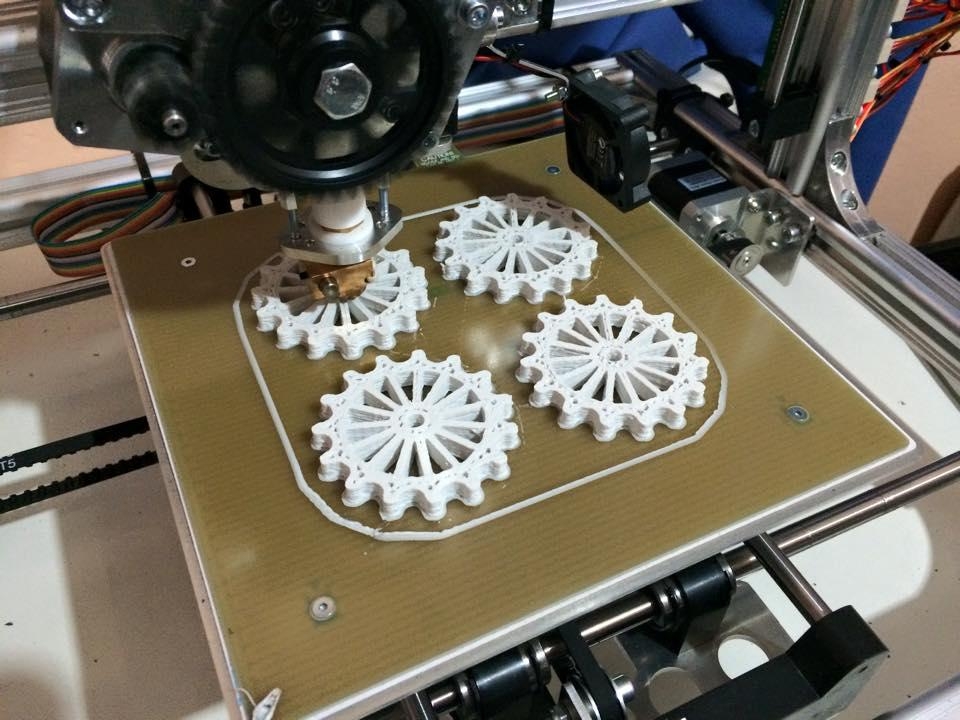

3D printing has revolutionized manufacturing and design. With advancements in technology, it’s now possible to create complex shapes and geometries with ease. However, one of the biggest challenges in 3D printing is the use of supports. They have a significant impact on print quality and can be time-consuming to remove. Is it possible to 3D print without support?

Many 3D printing enthusiasts have been searching for ways to avoid using supports. It’s not only an issue of time and effort, but also supports waste material and can sometimes affect the surface quality of the printed object. However, printing without support structures is not always an easy task, especially when it comes to intricate designs and overhangs.

If you’re looking for ways to improve your 3D printing experience, even without support, you’ve come to the right place. In this article, we will discuss different ways to 3D print without using supports, and how you can optimize your prints to achieve the best results. With a few tips and tricks, you’ll be able to print complex models with ease and minimal post-processing.

How to 3D print without support?

One of the most effective ways to 3D print without supports is to ensure that your instructions are as precise as possible. Pay attention to all of the details, such as wall thickness, layer height and infill percentage. This way, you can avoid any warping or other issues that could arise due to incorrect settings.

Choose materials wisely. Not all materials are suitable for printing without supports; for example, ABS is less likely to warp than PLA.

Be mindful of the orientation of your models. Try to print with the overhangs facing downwards so gravity can provide support during printing.

Use a slicing software that supports “proximity supports” or “smart supports.” These features generate structures only where needed, which makes it easier to remove them after printing.

Use bridging techniques to create structures with overhangs. This involves manually adding filament bridges between two points of the model that need support.

Finally, use a higher nozzle temperature. This can help reduce warping and improve adhesion to the print bed.

By following these tips, you can 3D print without supports and achieve great results. With a little bit of practice and experimentation, you’ll be able to create complex structures without the need for supports.

Can you 3D print holes without supports?

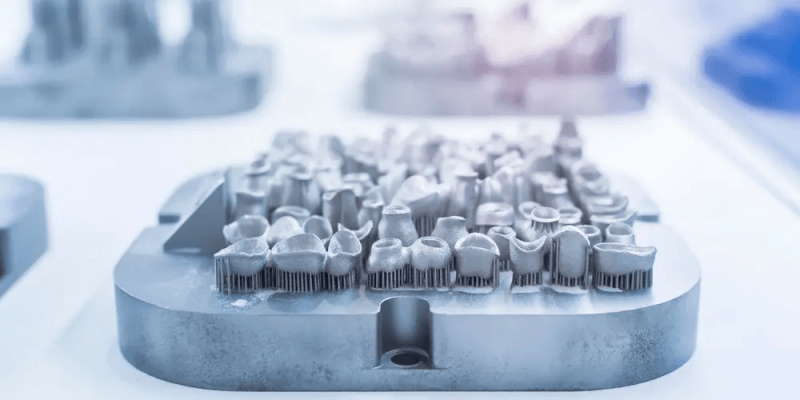

The development of 3D printers has allowed users to easily produce complex models and small parts with ease. One of the most common questions that people have when faced with this technology is if it’s possible to 3D print holes without supports. The good news is that the answer is yes! For those who have a well-calibrated 3D printer and optimal temperature settings, you can actually create good quality holes for your prints without having to use any additional support material.

However, as 3D printing is inherently a layer-by-layer process, it can be tricky to get the perfect hole shape printed out. To combat this issue, you may need to make some adjustments to your CAD software or model before sending it off for printing. If you are attempting a more complex model with larger holes then you might need the assistance of supports, depending on how well the 3D printer’s extruder handles print overhangs during this phase of production. Nevertheless, understanding that it is indeed possible to produce a hole in a 3D printed part without support will prove invaluable in setting up your printing projects correctly!

How to 3D print spheres without supports?

It is definitely possible to 3D print a sphere without having to use supports. To achieve this, you can start by splitting it into two. There are various splitting tools available online which can help you in this process. For an in-depth tutorial on how to do that, I highly recommend referring to my “How to Split and Cut STL Models for 3D Printing” guide. Once split, the two parts of the sphere have to be printed separately and then attached together using post-processing.

An interesting way of creating perfect spheres without having to use supports was demonstrated by My Tech Fun in one of their videos. Here, they started by dividing the sphere into two hemispheres and making holes in each hemisphere before attaching them together with some minor post-processing work that typically takes 10-15 minutes of effort. This technique proves to be a more efficient option compared to printing one large solid object due to the decreased time taken for printing a couple of separate parts instead of one big object.

If you want to 3D print a sphere without the need for supports, it’s important that you follow instructions carefully. This includes slicing your model correctly and making sure your printer is calibrated properly. Using a slicer such as Cura or Slic3r will make it easier to get the best results.

Experimentation. There are various techniques available when it comes to 3 D printing without supports and you may need to try out a few of them to find the one that works best for your printer. Making use of trial and error is a great way to find out which methods can produce the most reliable results.

Can you drill a hole in PLA & 3D prints?

Drilling a hole into PLA and other 3D prints can be done, but it requires an extra level of care compared to other materials. Specifically, you should avoid drilling parallel to the layers of the print, as this can cause layer splitting. Additionally, it’s highly recommended that holes in your part be pre-designed when creating the digital model. This ensures that they are more easily drilled while yielding better results. ABS filaments are generally more drills friendly than PLA given its increased strength and flexibility.

When starting the drilling process on a PLA or 3D printed item it’s important to make sure you’re using a slow speed setting on your drill bit so as not to overheat or melt the plastic. Furthermore, if you’re printing parts with curves or other complex shapes then you may need to use specialized drill bits such as forstner bits for improved success rates. At the end of the day, with proper preparation you can certainly drill holes in PLA and 3D printed parts with solid results.

When 3D printing models with holes, there are a few tips you should keep in mind before printing. Firstly, ensure that the hole is fully enclosed within the model’s geometry for better results. Secondly, use a thin wall thickness around your hole to avoid any unnecessary support builds. Finally, when slicing your model in preparation for printing, make sure to configure your software settings to print with a brim or skirt around the hole to ensure that it comes out correctly. With all these considerations in mind, you should be able to achieve great results when 3D printing models with holes!

How to 3D print without supports?

3D printing without supports is a great way to improve the quality, efficiency and time of your 3D prints. It can be achieved by lowering your layer height, decreasing the print speed and reducing the temperature in order to achieve better overhang angles, so you won’t need any supports. You can also try changing the part orientation to see if it can print without supports. Splitting the print into different parts can also help in minimizing or eliminating the need for supports during a 3d printing process.

The best 3D prints are usually those that don’t require using too much supports as it reduces a very time-consuming and often harmful-to-the-print part of the post-processing phase. In some cases however, it is impossible to create without adding supports which is why several techniques have been developed in order to minimize their usage or even remove its need altogether. The first step that one should take when attempting such an endeavor is to tweak slicer settings according to their printer type and the material being used for printing. This step can lead to significant improvements in terms of quality and time needed for completing any 3d printing project.

When 3D printing without supports, other methods need to be taken into account in order to achieve the best results. For example, adding brim or rafts can provide additional stability and help reduce warping or curling of the print. Additionally, using a higher flow rate for the filament can also help produce better overhangs by increasing the pressure on these features; this tactic should however be used with caution as too much pressure can cause the extruder to clog or even break. Finally, some printers also come equipped with a dual-extrusion system that allow for support materials such as PVA or PVA-based filaments to be printed within the same job. This option can greatly reduce post-processing time and improve the overall product quality.