How to fix 3d printer stringing?

Are you frustrated with your 3D printer stringing? Do you find yourself wasting hours of time and material cleaning up messy prints? Stringing is a common problem faced by 3D printing enthusiasts, but the good news is that it can be fixed.

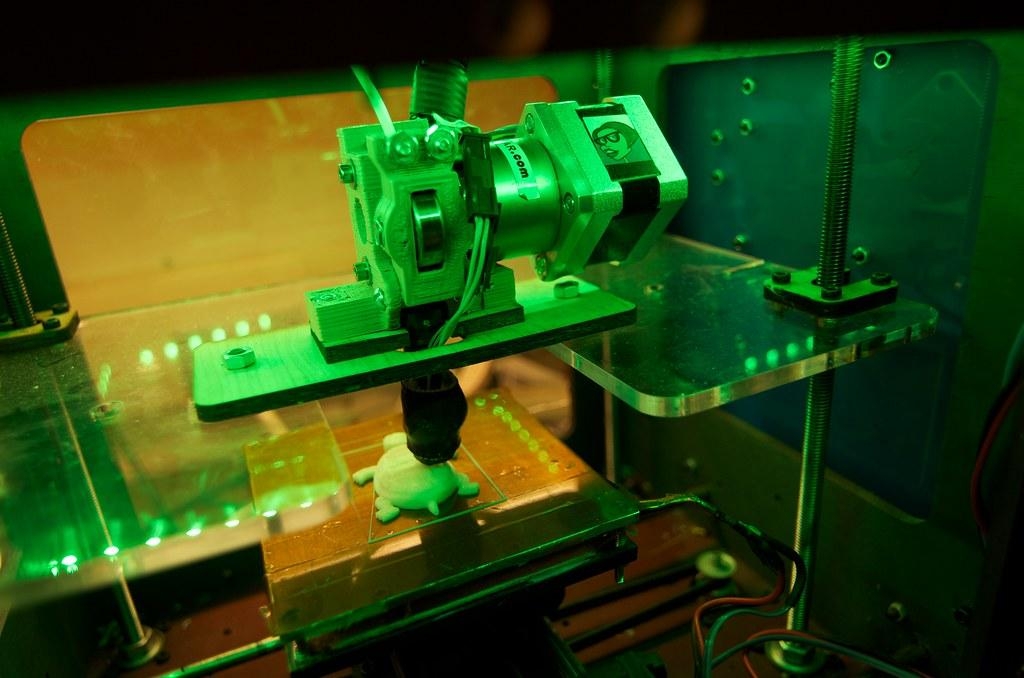

Stringing occurs when small strands of melted plastic are left behind on a 3D print, resulting in a web-like appearance. It happens when the printer nozzle is not retracted properly, causing the filament to continue oozing as the nozzle moves across the print bed. Stringing can be frustrating, not only because it messes up the appearance of your prints, but also because it can cause damage to your printer.

Thankfully, there are simple and effective ways to fix 3D printer stringing. In this article, we will dive into the most common methods for dealing with stringing and provide tips to help you prevent it from happening in the first place. With a little bit of knowledge and some adjustments to your printer settings, you can say goodbye to stringing and hello to clean, beautiful prints.

How to fix 3D printer stringing?

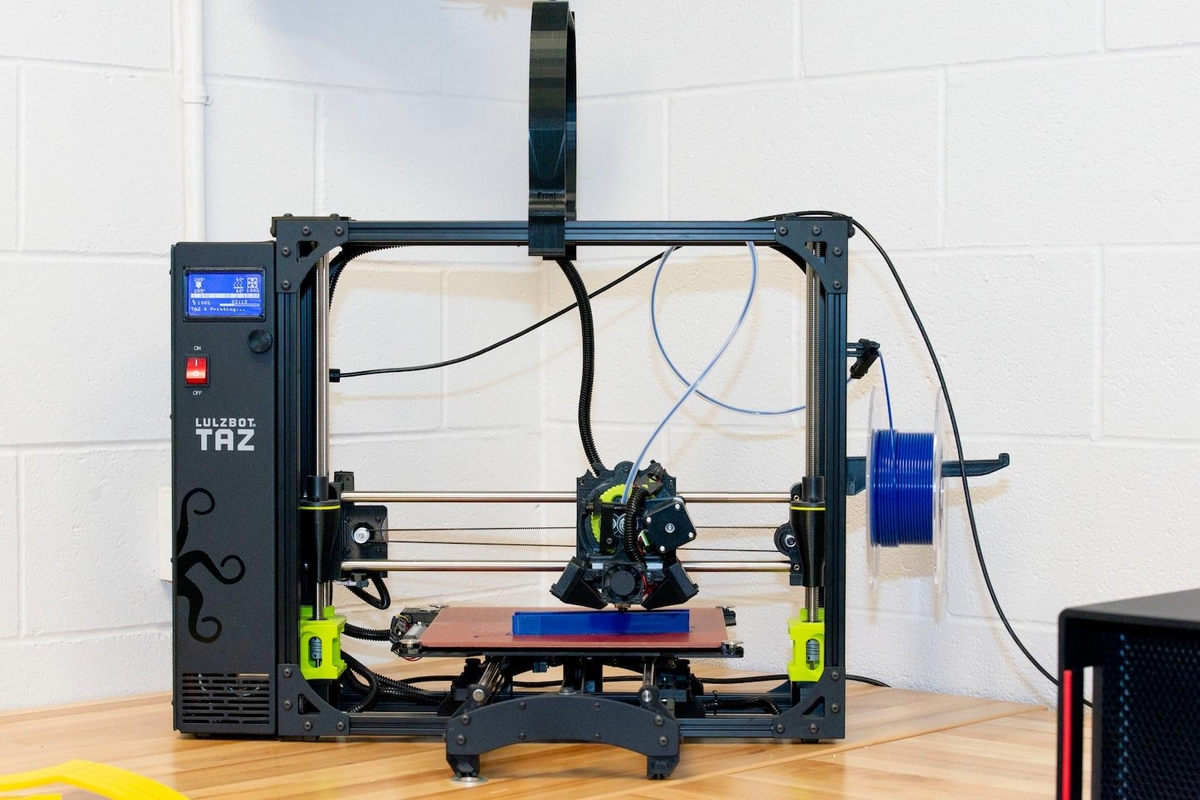

Before making any adjustments to your printer settings, it is important to read the instructions provided by the manufacturer and make sure you understand them. Always follow safety protocols when working around 3D printers.

Adjust nozzle temperature. The optimal nozzle temperature for your particular type of filament will vary depending on the brand and formulation. Generally speaking, a higher printing temperature will result in less stringing, but it is important to stay within the recommended range to avoid damaging your printer.

Change retraction settings. Retraction is the process of quickly pulling back the filament between moves to prevent ooze. If you are experiencing stringing, you may need to adjust the retraction settings in your slicer software. A general rule of thumb is that a longer retraction distance and slower speed will result in less string ing.

Increase fan speed. Increasing the fan speed on your 3D printer will help cool down the melted filament, reducing stringing. This is especially important for prints with small features or sharp angles, as higher speeds will help to solidify the plastic faster and prevent oozing.

By making a few simple adjustments to your 3D printer settings and understanding how stringing works, you can say goodbye to messy prints and start producing beautiful, clean models.

Once you have identified the likely cause of your 3D printer stringing, it is important to carefully follow the instructions provided by the manufacturer. This includes reading safety protocols and understanding the recommended settings for your particular brand and model of printer.

Check filament type. Different types of filaments will require different nozzle temperatures, retraction settings and fan speeds in order to produce clean prints. Be sure to read the instructions provided with your filament and adjust your settings accordingly.

Clean the nozzle. If you are still experiencing stringing after making adjustments to your printer settings, you may need to clean the nozzle. Use a thin wire such as a guitar string or dental floss to scrape any residue that may be clogging up the nozzle opening.

In order to achieve consistent results, it is important to follow the instructions provided by the manufacturer. This includes understanding your printer’s capabilities and limitations and adjusting settings based on the type of filament being used. It is also a good idea to run a few test prints before starting a large print job to make sure everything is working properly.

What causes filament stringing?

Stringing, also known as ooze, is an issue that can occur when 3D printing with filament. This is a very common problem that results in long strands of plastic being left on and around the print, attaching parts of the model together and making it appear unprofessional or messy.

There are several things that can cause filament stringing. First, incorrect retraction settings can cause unwanted oozing during movement of the nozzle between areas of printing. This occurs because when the retraction settings are too low or too high, plastic will be pulled back through the hotend instead of being correctly purged out at each move point transition. Second, excessive nozzle temperature can lead to more melted plastic than intended which causes excess ooze and stringing between areas where it shouldn’t be. Finally, having filament exposed to humidity before being sent to print can negatively affect the material’s characteristics by altering its melting point and viscosity which leads to stringing while printing.

Humidity

When 3D printing with filament, it is important to make sure that the material used is dry and of the best quality. High humidity can interfere with the printing process by making it difficult to adjust the print mode when using wet filament. Therefore, it is essential to monitor humidity levels in order to ensure successful prints. Materials such as PLA, PETG and ABS are less likely to absorb moisture due to their characteristics but users should be attentive when working with wet filament to prevent any problems from arising.

Manufacturers offer drying modes for most of their consumables to help combat humidity related issues and provide customers with the highest quality results. Signs of excessive humidity can be detected through loose surfaces on parts or lint found along a thread’s length. This can indicate that new filament needs to be purchased in order for a successful print or that damp conditions need to be eliminated from the environment. In conclusion, monitoring humidity levels can go a long way towards helping one produce better quality 3D prints.

Incorrect feeding and temperature

The extruder of a 3D printer must be provided with precise feed and adequate temperature regime in order to ensure reliable and aesthetically pleasing result. Incorrect feeding or unsuitable temperature settings can be indicative of over extrusion, an issue that manifests itself with distinct characteristics such as oozing blobs, distorted geometry, ribbed horizontal surfaces and strings formed by excessive plastic leftover during the nozzle’s idle movements.

To check the temperature mode, 3D printers owners can use “temperature towers”, a sequence of vertically positioned identical elements printed at different nozzle temperatures. Unlike wet filament error that can be detected separately, incorrect feeding and insufficient or excessive temperatures will generally both need to be taken into account and controlled sequentially in order to obtain successful prints. With correct settings defined and maintained throughout the printing process, it is possible to get excellent results from 3D printing.

Incorrect retraction

Retraction is an important feature for Fused Filament Fabrication (FFF) 3D printers. It is used to prevent unwanted plastic from leaking from the extruder nozzle while moving between two print points or onto a non-print area. The two primary settings that control retraction are length and speed. If the length is set too low, it can result in stringing of the filament and insufficient material fed when the nozzle resumes its printing task. If it is set too high, then thread stretching as well as plastic entering into the cold zone may occur and could eventually lead to plugging of the extruder.

Similarly, if the retraction speed is set too quickly, there is a greater chance that either filament breakage will occur within the melt zone or feed slippage when exiting out of that area. Therefore, it is critical to calibrate these retraction settings correctly for successful 3D printing jobs and to achieve overall good results with minimal waste of filament material. Additionally, one should always take into account their specific printer model and its mechanical capabilities when adjusting each of these parameters.