What is sla 3d printing?

Have you ever heard of SLA 3D printing? It’s a technology that has been rapidly gaining popularity in the world of 3D printing. But what exactly is it?

3D printing has revolutionized the way we create objects, from small toys to large industrial parts. SLA 3D printing is a type of additive manufacturing technique that uses a specific type of resin to create highly detailed and accurate parts.

SLA 3D printing, or stereolithography, is a method that uses a laser to cure liquid resin into solid objects. It offers high precision and accuracy, making it ideal for creating intricate and detailed models. In this article, we’ll explore the ins and outs of SLA 3D printing and how it works. Whether you’re a 3D printing enthusiast or just curious about the technology, read on to learn more.

With SLA 3D printing, you can create intricate and precise parts that are not possible with traditional manufacturing methods. In this article, we will delve deeper into what SLA 3D printing is, how it works, and its advantages over other 3D printing technologies. So, let’s explore the world of SLA 3D printing and discover its potential.

What is SLA 3D printing?

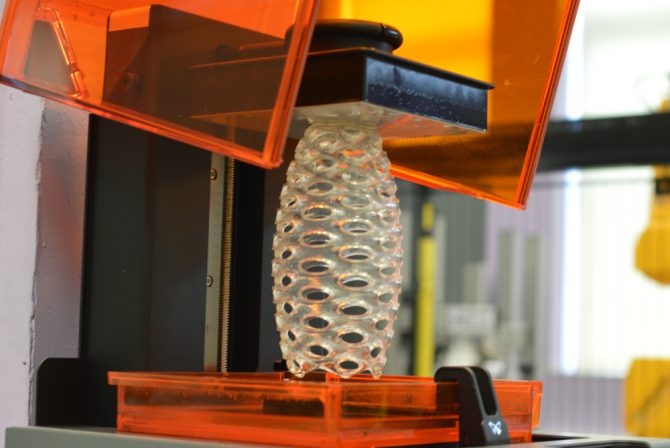

SLA 3D printing is a type of additive manufacturing that uses liquid resin as the printing material. The process begins with the use of an ultraviolet (UV) laser to cure the resin layer by layer until it forms a solid object. This method can be used to create parts with intricate details and high precision, making it ideal for model-making, prototyping, and production.

Unlike other 3D printing methods, SLA 3D printing offers superior accuracy and surface finish. It also allows for faster turnaround times, as the parts can be printed quickly in a single operation rather than multiple separate steps.

The major benefit of SLA 3D printing is its high resolution. The laser cures the resin layer by layer, meaning that it can create objects with intricate details and complex geometries. This level of precision allows for more accurate parts and prototypes, making it ideal for various applications such as dental prosthetics and jewelry.

SLA 3D printing is also versatile in terms of materials used . Currently, SLA 3D printers can use a variety of resins ranging from rigid to flexible, allowing you to create parts with different properties and applications.

SLA 3D printing has several other advantages over traditional manufacturing methods. For example, the technique requires less post-processing and no support structures are necessary. It also offers a high degree of control over the resolution and properties of the finished product. With SLA 3D printing, you can create complex parts with intricate details that would be impossible to make with traditional methods.

Another benefit of SLA 3D printing is that it is relatively inexpensive compared to other 3D printing technologies. As a result, the cost of creating prototypes and small batches of parts is much lower than with traditional methods.

How does SLA 3D printing work ?

SLA 3D printing is a fairly straightforward process. The first step is to prepare the model in a computer-aided design (CAD) program. Once the model is ready, it is sliced into thin layers, which are then sent to the printer.

The printer itself consists of a tank filled with liquid resin and a platform that moves up and down as the parts are printed. An ultraviolet (UV) laser then cures each layer of resin, creating a solid object. The platform then moves down and the process is repeated until the entire part is complete.

The main advantage of SLA 3D printing is its speed and accuracy. Since it uses a laser to cure the resin, it can create extremely detailed parts with high precision and accuracy. And since the process is done in one single operation, it can produce parts quickly.

What are the print parameters of SLA?

The print parameters for SLA 3D printing include layer height, curing time, and exposure time. Layer height refers to how thick or thin each of the layers is. Thicker layers result in a stronger part but take longer to print.

Curing time determines how long the laser should be left on each layer. A longer curing time results in stronger parts but can also increase the printing time . Exposure time determines how long the laser should be exposed to each layer. A longer exposure time results in stronger parts but can also increase the printing time. The optimal settings for these print parameters depend on the material used, so it is important to experiment with different settings to find out what works best for your particular application.

SLA 3D printing offers a number of benefits over traditional manufacturing methods. For example, it is much faster than other 3D printing technologies and can produce highly accurate parts and prototypes with intricate details. In addition, the process requires less post-processing and no support structures are necessary. Finally, SLA 3D printing is also relatively inexpensive compared to other 3D printing technologies, which makes it ideal for prototyping and small batch production.

What are the characteristics of SLA 3D printing?

SLA 3D printing is known for its high precision and accuracy, as well as its ability to produce complex parts with intricate details. The process also offers a wide range of materials, allowing you to create parts with different properties and applications.

Additionally, SLA 3D printing requires less post-processing than traditional manufacturing methods and no support structures are necessary. Finally, the cost of creating prototypes and small batches of parts with SLA 3D printing is much lower than with traditional methods.

SLA 3D printing offers a range of benefits compared to other 3D printing technologies. For example, it requires less post-processing and no support structures are necessary. Additionally, SLA 3D printing produces parts quickly and with high precision and accuracy, enabling you to create complex parts with intricate details that would be impossible to make with traditional methods. It also offers a wide range of materials, allowing you to create parts with different properties and applications.

Finally, the cost of creating prototypes and small batches of parts with SLA 3D printing is much lower than with traditional methods.

Curling

SLA 3D printing is a great solution for making parts that require high precision and accuracy, such as those used in the automotive and aerospace industries.

The process can also be used to create parts with intricate details, making it ideal for creating complex objects with small features. Additionally, SLA 3D printing offers a wide range of materials, allowing you to create parts with different properties and applications. Finally , the cost of creating prototypes and small batches of parts with SLA 3D printing is much lower than with traditional methods.

Layer adhesion

SLA 3D printing is also renowned for its high layer adhesion, meaning that parts printed with the technology are more durable and less likely to break or deform over time.

This makes SLA 3D printing ideal for creating highly detailed parts that require superior strength and durability. Furthermore, because SLA 3D printing requires little post-processing, it can be used to quickly produce prototypes and small batches of parts for testing and evaluation.