How long will a 3d printer last?

3D printing is a revolutionary technology that has changed the way we create, design, and manufacture objects. But with all the hype surrounding 3D printing, there’s one question that many people are asking: how long will a 3D printer last?

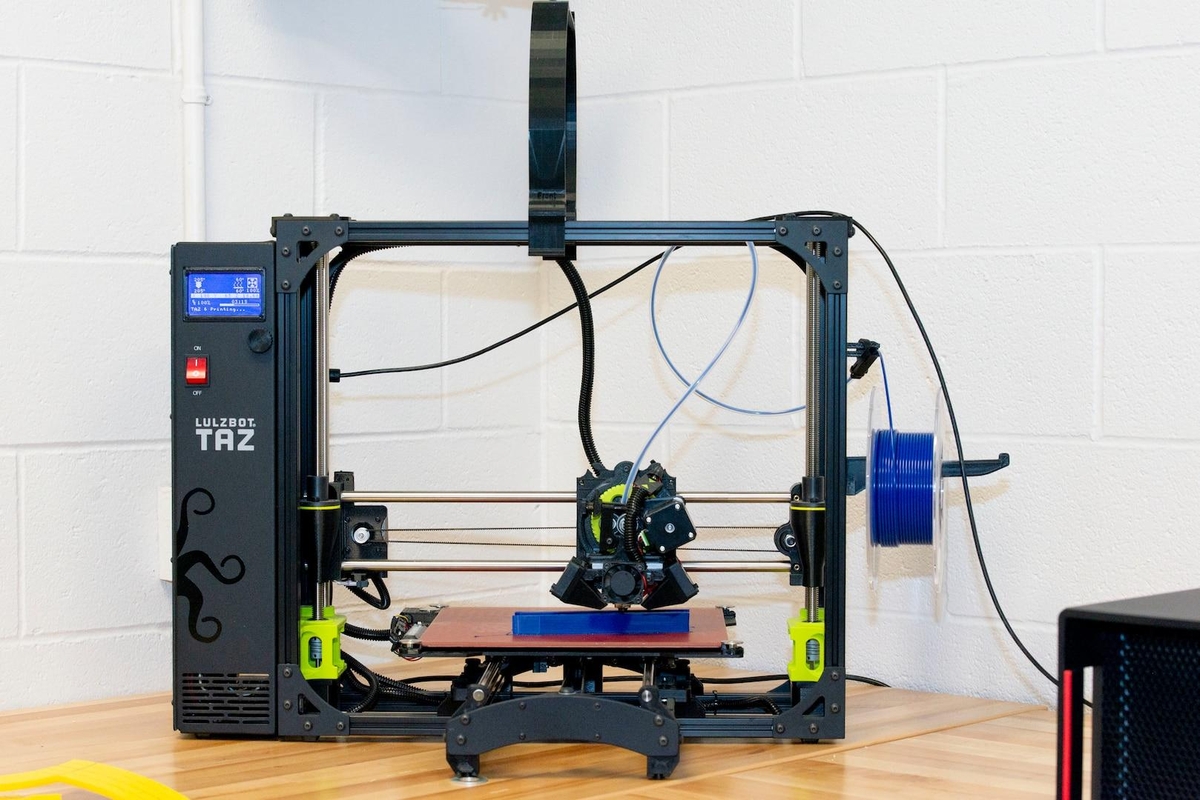

3D printers have become increasingly popular in recent years, with more and more people using them for both personal and professional projects. However, 3D printers are not cheap, and many people want to know how long their investment will last before they need to buy a new one.

The lifespan of a 3D printer can vary depending on several factors, such as the quality of the components, the frequency of use, and the maintenance and care it receives. In this article, we will explore the different factors that can affect the lifespan of a 3D printer and provide some tips on how to extend its longevity. So if you’re considering investing in a 3D printer, or if you already own one, keep reading to find out how long your 3D printer is likely to last.

How long will a 3d printer last?

No one likes wasting their hard-earned money, especially when buying something as expensive as a 3D printer. When weighing your options you want to be sure you’re picking the model that will last you the longest. Knowing how long a 3D printer is expected to last can help make that decision easier.

Factors such as how often it’s used and how well it’s maintained have an influence on lifespan, so you have a direct impact on how long your 3D printer lasts. Many high-end models tend to have longer lifespans but this isn’t necessarily true for all brands, so do research before purchasing your 3D printer to ensure you’re getting what you need for the best value. Additionally, think about whether or not it would be more advantageous to replace select parts of your machine rather than going through the entire effort and cost of replacing it altogether. Exploring this option can often extend the lifespan of your existing 3D printer significantly with some simple maintenance.

How many printing hours does a 3d printer have?

One of the biggest questions when it comes to 3D printing is just how long will a machine last? The answer depends on how it’s maintained. A good printer should last approximately 10 years, and if it were used four hours each day then the total number of hours that the machine could hit in its lifespan could be about 7,500-15,000. But to ensure that your printer does last for this amount of time and hits those numbers, you have to put in the work. This entails routine replacements and repairs. It also involves fine-tuning many parts of the machine throughout its life to secure a long lifespan.

But beyond simply making sure your 3D printer lasts as long as possible, regular maintenance will give you some notable advantages too. This can include increased printing capabilities due to an optimized design. Additionally, speed and quality can also improve because nooks and crannies within the printing structure are properly cleaned out. Thus, while it is important to keep track of just how many hours a 3D Printer has left in its lifespan, investing energy in maintaining the printer can extend that lifespan while also providing quality prints at increased speeds too!

What causes 3d printer breaking?

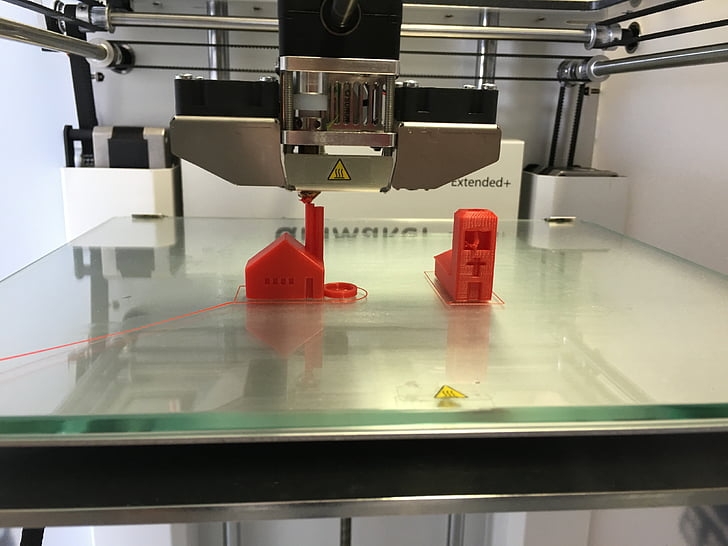

3D printing, the process of creating three-dimensional objects from a digital file, has become an essential in many manufacturing, engineering and creative fields. Since its emergence as a viable technology, there have been various advances that have followed to make the 3D printing experience smoother and more reliable for users. Yet despite all these advancements, 3D printer breakages still occur as some internal component of the printing machine can cause malfunction or even physical damage to itself.

One such component would be the wiring within the 3D printers themselves. Over time and with frequent use, printed wires can become vulnerable to breaks due to their propensity for frequent bending and movement. Replacing these short-term parts with premium flex cables could help prevent any breakdowns owing to this factor. Another reason why breakages happen is when users decide to install customized designs and upgrades onto their printers in order to gain an advantage in terms of performance or design aesthetic during competitive print jobs. While this may indeed offer certain benefits, it could also potentially lead to risky hardware tinkering which might cause more damage than good. To optimize performance while avoiding any potential malfunctions as a result of experiments gone wrong, it’s best to make sure your 3D printer is properly stocked with the right parts and upgrades. These components should be tailored to fit your specific printing needs and should not be beyond your printer’s capabilities.

What can you do to ensure your 3d printer lasts longer?

Having the right 3D printer is important for a long-lasting machine. Reputable brands are both reliable and durable, so buyers should do their research before investing in one. Read reviews from other customers to get an idea of what printer models have had success and which should be avoided. Having this information in mind beforehand can save time and frustration when using the printer and ensure that it lasts a long time.

In addition to choosing the right machine, having knowledge about servicing needs is vital to keep it running well over time. Knowing which parts often require replacing or updating, along with understanding recommended maintenance intervals and requirements, can save money in repairs and replacement fees while making sure the device runs well long term. Being aware of industry news concerning product recalls or specific errors related to certain machines can also help ensure that any technical issues are addressed quickly before they become expensive problems later on.

Finally, regular cleaning and lubrication of all parts as well as occasional calibration of the printer can help extend its life significantly. Cleaning the nozzle and other parts with a soft cloth after each job is essential to ensure that residue does not accumulate, causing clogs and eventually damage over time. Adding lubricant to the moving parts will also prevent any premature wear and tear on the machine. Calibration should be done as recommended by the manufacturer to ensure that all parts are working in sync and that prints are accurate.

By doing these simple tasks, you can help increase the life of your 3D printer significantly and guarantee its performance over time.

The quality of the filament used in a 3D printer is another important factor when considering how long one will last. Filament that’s of a lesser quality or has been sitting on a shelf for an extended period of time can cause clogs, jams, and other problems that can significantly reduce the lifespan of a 3D printer. To ensure optimal performance and longevity, only buy filament that’s high in quality and certified safe for use in 3D printers.

Proper maintenance practices for your 3d printer

Maintaining and properly caring for your 3D printer is essential for ensuring a long life and great results. To ensure that your 3D printer functions at its peak performance, proper maintenance practices must be observed and adhered to. There are several ways in which you can maintain the condition of your 3D printer in order to maximize its lifespan.

First, the bed level should be checked regularly due to the vibrations caused by printing processes. Bed leveling should also be adjusted when needed, especially after changing filaments or nozzle sizes. Second, using the proper cooling fan speed and keeping it clean will help prevent debris from causing clogged or blocked nozzles. Third, it is important to regularly check all components of the printer for any wear and tear that may have occurred over time such as loose wires and fasteners since these issues can lead to faulty prints. Finally, all moving parts should be lubricated regularly with an appropriate lubricant in order to keep them functioning properly and reduce noise levels while printing. Following these steps will help ensure a reliable and consistent print quality with fewer instances of failed prints due to machine failure or other issues like jamming or poor layer adhesion.

Keeping your 3D printer on a regular cleaning schedule will help to ensure its lasting performance. Clean the nozzle after every print and keep the build plate free from debris and dirt. Regularly check the extruder for any clogged or blocked filaments, and replace old, worn out parts in a timely manner. Additionally, make sure that all moving parts are well lubricated with an appropriate lubricant for smooth operation. Following these maintenance tips will help to ensure that your 3D printer lasts for many years.