3d printer not printing correctly

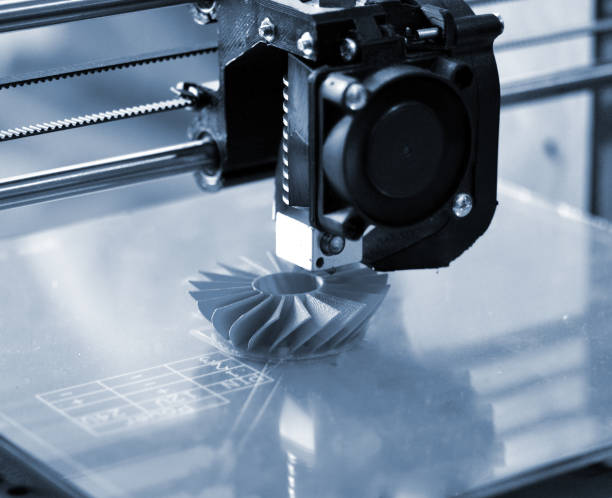

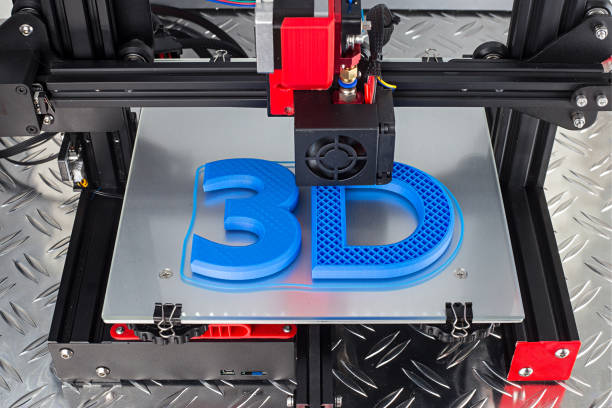

Have you ever experienced frustration when you sit down to print a 3D model, only to find that your printer isn’t working as it should be? Perhaps your printer is producing messy prints, skips lines or even stopping mid-print. If you’re wondering why your 3D printer isn’t printing correctly, you’re not alone.

3D printing is a rapidly growing technology that allows for the creation of three-dimensional objects, creating endless possibilities for creativity and innovation. However, even the most advanced 3D printers can encounter problems, leading to print errors or complete failure.

If you’re struggling with 3D printer problems, don’t panic! In this article, we’ll explore the most common reasons why your 3D printer is not printing correctly and suggest some solutions to help you troubleshoot your printer and get back to printing beautiful, high-quality models.

Causes of Incorrect 3D Printing

Incorrect 3D printing can be caused by a number of factors, including the quality of filament used, incorrect settings on the printer, and external environmental conditions. Low-quality filament often does not adhere correctly to the build platform or extrude properly. This can lead to clogged nozzles, warping, poor adhesion between layers and uneven layers. It is important to ensure that all settings are correct before starting a print job, including layer height and temperature setting.

Furthermore, if the environment around the printer is too hot or humid it can affect the properties of the printed object. To avoid these issues it is important to use high quality filament and maintain an optimal temperature and humidity level in the environment around your 3D printer. In addition, regularly cleaning and maintaining your printer will help ensure that all parts are functioning correctly and free from dust or debris buildup which can interfere with proper printing.

Print Surface Issues

Print surface issues are a common problem for 3D printing. If the print surface is not properly prepared and/or maintained, it can lead to inaccurate prints, warping, and poor adhesion between layers.

It is important to ensure that the print surface is clean and free from any dust or debris before beginning a print job. The most common type of print surface is a heated build plate, which should be set to the optimal temperature for your filament material.

Additionally, certain types of materials require the use of an adhesive like hairspray or glue stick applied to the bed prior to printing. Depending on what type of material you’re using and what kind of printer you have, you may want to experiment with different surfaces such as BuildTak or PEI sheets. Maintaining your print surface correctly will help ensure that your prints come out accurately and without deformities or warping.

Nozzle Diameter & Retraction Distance

Nozzle diameter and retraction distance are two critical settings that need to be adjusted when 3D printing. The nozzle diameter is the size of the opening through which plastic filament is extruded from the print head.

Generally, nozzle diameters range from 0.4mm to 1.2mm and should be chosen based on the desired resolution of your prints. A larger nozzle diameter will create more visible layers, but less detailed prints. On the other hand, a smaller nozzle diameter will produce more detailed prints, but require multiple passes over a given area to achieve this detail.

Retraction distance is also important to adjust in order to prevent stringing and oozing that can occur during printing due to plastic filament melting inside the hot end of your printer. Retraction distance refers to how far back the filament is retracted before moving onto a new area of your print job; too long or short of a retraction distance can cause issues with your prints. Adjusting this setting correctly will ensure that your prints come out looking their best!

Poor 3D Model Design

Poor 3D model design can lead to a number of issues when printing, such as warped parts, poor surface finish, or incomplete prints. To avoid these problems, designers should pay special attention to their 3D models before sending them for printing.

First and foremost, the wall thickness of a model should be considered. If the walls are too thin, they will be prone to warping or even breaking during the printing process. It is important to think about the overall size of your model when considering its wall thickness; larger models will require thicker walls than smaller ones. Additionally, rounded edges and overhangs should be kept to a minimum in order for successful printing. Avoiding sharp angles and fine details will help reduce the chance of failure during production.

Finally, designers should consider how their model is oriented before sending it off for printing. The orientation of the model can have an effect on both print time and quality; orienting it in such a way that gravity works with it rather than against it can help ensure success. With these tips in mind, designers can create high-quality 3D models that are ready for printing!

Printing Process Parameters

Printing process parameters are key to successful 3D printing. These parameters include the type of material used, print speed, layer height, extruder temperature and more. By setting these parameters correctly, a designer can ensure that their model is printed with the highest possible quality.

Material selection is an important part of the printing process. Different materials have different properties which can affect the finished product. PLA is great for small parts and detailed models due to its strength and low melting point, while ABS is better suited for large parts due to its higher melting point and increased strength.

The print speed will also affect the quality of the finished product; too slow or too fast a speed can lead to poor surface finish or incomplete prints. It is important to find a balance between time and quality when setting this parameter; faster speeds will mean faster prints but may result in poorer quality compared to slower speeds where more time is taken on each layer.

Finally, the extruder temperature should be adjusted based on the type of filament being used; some materials require higher temperatures than others in order for them to melt properly and form a strong bond with other layers during printing. All of these factors come together to create a successful 3D printed part!

Printing Speed Settings

Print speed is a critical parameter when 3D printing, as it affects the quality of the finished product. Too slow or too fast a speed can lead to poor surface finish or incomplete prints. To ensure optimal results, it is important to find a balance between time and quality when setting this parameter; faster speeds will mean faster prints but may result in poorer quality compared to slower speeds where more time is taken on each layer.

The type of material used also plays an important role in determining the print speed settings; PLA and ABS materials require different temperature ranges and speeds for successful results. It is also important to consider any other factors such as layer height, nozzle diameter, number of perimeters and infill percentage when adjusting the print speed settings. By doing so, designers can ensure that their model is printed with the highest quality possible.

Flow Rate Adjustment Issues

Flow rate is another important setting to consider when 3D printing. It is the rate at which the material is being extruded from the nozzle, and it can cause problems if it’s not calibrated correctly. If the flow rate is too low, then there will be gaps in the layers of the model and prints may fail due to under-extrusion.

On the other hand, if the flow rate is too high, then there will be an excessive amount of material deposited and this can lead to poor surface finish or clogged nozzles. T

To prevent these issues, it is important to adjust the flow rate accordingly so that all parts of a 3D print are properly filled out. This involves calibrating both the filament diameter and nozzle diameter as they are connected to each other. Additionally, users should also take into consideration any changes in temperature or pressure that could affect how much material flows through their printer. By adjusting these settings correctly, 3D printing enthusiasts can make sure their prints look great every time!

Print Temperature Variations

Print temperature is one of the most important settings to consider when 3D printing. It is the heat applied to the filament as it passes through the nozzle and can have a major impact on how well objects are printed. If the temperature is too low, then there will be gaps in the layers of the model and prints may fail due to under-extrusion.

On the other hand, if it’s too high, then there will be an excessive amount of material deposited and this can lead to poor surface finish or clogged nozzles. To prevent these issues, users should adjust their print temperature accordingly depending on what type of filament they are using.

For example, higher temperatures work better for more flexible materials such as ABS while lower temperatures work better for more rigid materials such as PLA. Additionally, users should also take into consideration any changes in ambient temperature that could affect how hot their printer gets during a print job. By adjusting these settings correctly, 3D printing enthusiasts can ensure their prints come out looking great every time!

Quality Control Problems

Quality control problems are a common issue that 3D printing enthusiasts face when attempting to create complex objects. If the design of a model is not correct, or if there are errors in the filament used, then the parts may not fit together properly or may be too weak to support the weight of other components.

Additionally, incorrect settings can lead to poor surface finish or over-extrusion which can cause clogged nozzles and jamming. To prevent these types of issues, it’s important for users to double-check their designs and settings prior to beginning each print job. Additionally, it’s also important to inspect finished prints for any signs of defects before removing them from the printer. Taking these steps will help ensure that 3D prints come out looking great every time!