How many hours does a 3d printer last?

When you invest in a 3D printer, you want to make sure that your investment is worth it. But how long can you expect your 3D printer to last? Is it a one-time purchase, or will you need to replace it after a certain amount of time?

3D printing technology has come a long way since its inception. 3D printers are now widely available and are used in various industries, from automotive to aerospace, education to healthcare. However, like any technology, 3D printers have a lifespan that varies depending on several factors.

If you are planning to buy a 3D printer, you need to consider its longevity. Knowing how long a 3D printer lasts can help you make an informed decision and plan your budget accordingly. In this article, we will discuss the different factors that affect the lifespan of a 3D printer and give you an idea of how many hours you can expect your 3D printer to last.

How many hours does a 3d printer last?

A 3D printer can last a long time depending on how it’s treated and the brand used. Generally, 3D printers won’t need to be replaced for several years. The best 3D printers often come with warranties of up to three years, meaning they should remain functional within that window of time. However, some printer models may last even longer if cared for properly. Different factors affect the longevity of a 3D printer including its usage frequency, maintenance frequency, and type of materials used in printing.

In addition to the material being printed, cleaning and upkeep are essential for extending the lifespan of a 3D printer. It’s important to follow manufacturer instructions as well as parts replacement directions provided with each machine. Users must also keep an eye on wear parts such as nozzles and heaters so they can spend extra money on replacement items when these components get worn out. A projector’s lifespan will depend on usage too; most projectors are designed to last around five years or more based on regular use—at least 2500 hours of use per year is recommended for optimal performance over extended periods of time.

How many printing hours does a 3D printer have?

3D printers can be very reliable machines when you take care of them properly. When kept in good condition, it’s expected that a 3D printer can have a lifespan of around 10 years. This means that the machine should last at least four hours daily during those 10 years, giving you a total of about 7,500 to 15,000 printing hours. However, this is only possible if the machine is proper looked after and regularly serviced.

When servicing your 3D printer, you don’t just keep it going for longer; you help improve its reliability and performance. Replacing worn out parts and doing basic repairs as needed are essential steps to keep the printer running smoothly. Additionally, effective fine-tuning goes beyond simple replacements – it also helps adjust and optimize individual components to ensure uniform heating throughout various layers of your prints, reducing wrinkles and deformities. As such, maintenance not only extends the lifetime of your machine but also improves its overall printing effectiveness significantly too.

What causes 3D printer breaking?

The various causes of a 3D printer breaking can be attributed to the use of inferior-quality parts and accessories. The majority of 3D printers have several components, some of which need to be replaced frequently. Wires in particular are one such component whose structure renders them prone to permanent breakages over time if they’re not maintained properly. If your printer has shorter-lived flex cables, this will end up costing you more money as you may find yourself having to replace them every so often. Additionally, those in the printing business love pushing the boundaries with innovative designs and upgrades in order to stay ahead of the competition; however, these experiments can prove negative for 3D printers as certain aftermarket parts may not fully be compatible with their systems, thus causing irreparable damage or breakdowns.

Preventing breakages is possible by regularly inspecting the 3D printer for any faults or wear and tear that needs addressing. Furthermore, ensuring that all parts and accessories used are good quality will ultimately extend its life for many years. Keeping software updated on a regular basis is important too as faulty programs or firmware can cause instability which could lead to a breakdown of your 3D printer eventually down the line. It’s better to be safe than sorry, so keep up with maintenance and servicing your 3D printer.

What can you do to ensure your 3D printer lasts longer?

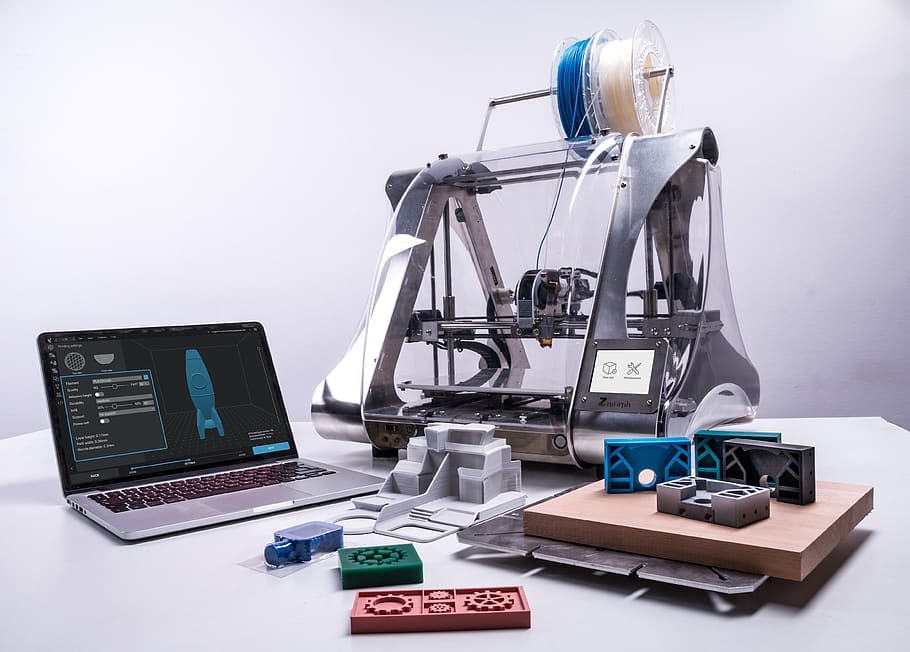

To ensure that your 3D printer lasts as long as possible, it is important to start by selecting a reputable brand. When making this purchase, it is wise to research the product thoroughly. Reading customer reviews and considering the feedback of experienced users can help you find a reliable model that will hold up over time. Once you have purchased the right machine, it is key to learn how to properly care for and maintain it.

Knowing when and how to service your printer can help extend its life span significantly. Common tasks include cleaning its nozzles, replacing worn parts, regularly recalibrating components, and periodically lubricating moving parts. Additionally, following the manufacturer’s guidelines for regular maintenance should be adhered to in accordance with the digital manual included with each machine. Proper maintenance also requires being aware of common problems such as clogs or jammed layers that may lead to machinery damage. Becoming knowledgeable about basic preventive measures will not only maximize performance but lengthen its lifespan too.

Proper maintenance practices for your 3D printer

Maintaining your 3D printer is essential to ensure its optimal performance, longevity, and safety. It includes regular cleaning of the printer and its components, quality filament selection, and proper temperature settings. The following tips can help keep your 3D printer in top condition:

First, keep the 3D printer clean. It’s important to clean out every part of the machine- including the nozzle, printing bed, extruder head, filament feeder gears, fans, and other moving parts- on a regular basis with a soft brush or compressed air. Not only does this prevent dust and dirt build-up that can affect printing results but it also helps reduce wear on these components over time. Additionally, make sure to inspect all components for any loose screws or worn parts before each print which will help reduce print errors.

Second, use quality filament for higher success rates and better prints. Pay attention to “tolerances” when selecting filaments; make sure that the materials you are using have been tested in your specific 3D printer model for optimal results. Finally, finding an optimal temperature setting is key for good adhesion between layers and avoiding warping of prints from inaccurately heated plastics. Make sure you read the manufacturer’s guidelines on suggested temperature settings.

To sum up, 3D printers generally have a long life span and can last for many years if they are properly maintained. Ensuring that all parts and accessories used are good quality will extend its life significantly, as well as regularly inspecting the 3D printer for any faults or wear and tear that needs addressing. Additionally, properly cleaning and servicing your 3D printer, using quality filaments, and setting the correct temperatures are all important steps in extending its life. With proper maintenance and care, a 3D printer can last for many years.

1. Always keep the filament nozzle clean

Maintaining a clean filament nozzle is important for 3D printing. It ensures that the 3D print quality is consistent and good, and prevents any clogs that could compromise its design. To keep the nozzle clean and working properly you should use an appropriate cleaning tool regularly, before and after each print job. This will help to prevent any inconsistencies occurring in the filament flow, which can affect the finished product.

It is also good practice to replace the filament nozzle after a certain amount of prints, especially if it has been heavily used or show signs of prolonged wear. Although nozzles are consumables, their replacement should be done as a last resort for optimum printer performance. Taking time to routinely inspect and clean your nozzle should extend its life span significantly. Additionally, having back-ups on hand in case something goes wrong can save time and reduce sudden costs associated with replacements.

2. Replace nozzles

The 3D printer’s nozzle is the most essential element of any 3D printing process. It is the tiny point at which the filament goes through and melts before it comes out as a plastic object. The quality of your prints largely depends on how well your nozzle works. To ensure optimal performance, it is important to regularly replace or clean the nozzle of your 3D printer.

However, there isn’t a specific rule of thumb guiding individuals on how long exactly your nozzle should last before it requires replacing. Generally speaking, it is good practice to change this consumable every three to six months depending on various factors like the system you have, what kind of filaments you use and most importantly; how often you use your printer. High end printers generally require less frequent changing than low-end ones while materials like PLA don’t need as much attention as other heated filaments like ABS and Nylon. Taking this into consideration will help maintain optimum performance while ensuring cost-efficiency and a longer lifespan for your printer.

3. Regularly lubricate the machine

The importance of regularly lubricating a 3D printing machine cannot be overstated. Without regular lubrication, the machine’s components will experience wear and tear much sooner than they were designed to last. Friction between parts can cause excessive heat buildup and shorten the life of the machine. A regular schedule should be established for applying the necessary lubricant to the moving parts of the machinery in order to reduce any likely damage.

Different types of lubricants may be suitable for different machines, so it is important to research what kind of lubricant your particular type of 3D printer calls for before you apply it liberally without knowing its effects on your equipment. Too much lubricant can attract dust and grime, effectively gumming up the mechanism and preventing it from working properly, so always follow instructions when using lubricants. For proper maintenance, make sure to frequently inspect your 3D printer and periodically apply appropriate amounts of lubricant as recommended in order to prolong its lifespan while keeping it running optimally.