3d printer repair how to fix your machine

Are you having trouble with your 3D printer? Is it not functioning properly or producing low-quality prints? Don’t worry; you’re not alone.

3D printing has revolutionized the manufacturing industry, allowing for the creation of complex and customizable objects. However, like any other machine, 3D printers can break down or malfunction.

If you’re experiencing issues with your 3D printer, it’s essential to identify the problem and fix it promptly. Repairing a 3D printer can be intimidating, but it doesn’t have to be. With the right knowledge and tools, you can fix most issues yourself. In this article, we’ll discuss some common problems you may encounter with your 3D printer and how to fix them.

Have you ever experienced a malfunctioning 3D printer? It can be frustrating when your machine isn’t working properly and you’re not sure how to fix it. But fear not, because with a little troubleshooting, you can get your 3D printer back up and running in no time.

3D printing has become increasingly popular in recent years, with more and more people using these machines for a variety of purposes, from creating prototypes to making personalized gifts. However, like any other machine, 3D printers can break down or malfunction over time, and it’s important to know how to fix them.

If you’re experiencing problems with your 3D printer, don’t panic. There are several common issues that can be easily fixed with a little know-how. In this article, we’ll take a look at some of the most common 3D printer problems and provide you with step-by-step instructions on how to troubleshoot and fix them. So, let’s get started!

What is a 3d printer?

A 3D printer is a piece of technology that uses a process called additive manufacturing to create three-dimensional objects from digital files. It works by depositing thin layers of material, such as plastic or metal, one on top of the other until the desired object is formed. This type of printing has revolutionized the way products are made, allowing for the creation of complex and customizable objects.

One of the most common problems you may encounter with your 3D printer is a clogged nozzle. This can be caused by improper filament loading or using low-quality filament, and it can result in poor printing quality or uneven layers. To fix this issue, you’ll want to first remove any excess filament from the nozzle, then prime the nozzle to get it flowing again. You can do this by heating the nozzle to the right temperature and using a tool to push filament through.

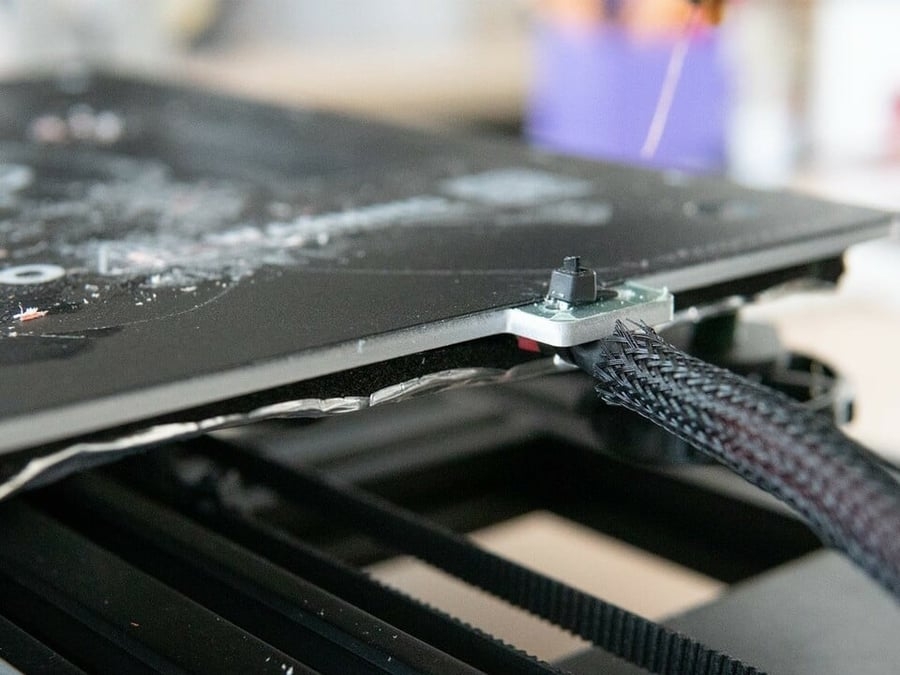

Another issue that can arise with 3D printers is an improperly leveled build plate. If your printer’s build plate is not level, it can cause uneven layers or objects that don’t stick properly. To fix this problem, you’ll need to adjust the screws on the bottom of the printer so that they are evenly distributed. You can also use a piece of paper to check the level of the build plate and make sure it is even.

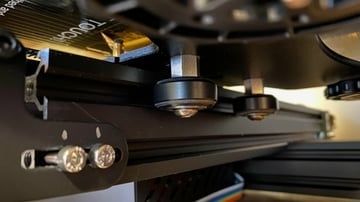

Finally, if your 3D printer is having trouble extruding filament, you may need to adjust the tension on the extruder motor. This can be done by loosening or tightening the screws on the motor until it is properly adjusted.

Maintenance vs. Repair

3D printer maintenance and repair are two different things. Maintenance is the process of keeping your 3D printer in good working condition by regularly checking for problems and cleaning it. Repair, on the other hand, involves fixing any issues with the machine when they arise.

For best results, it’s important to do both maintenance and repair on your 3D printer. This will ensure that it runs smoothly and that any problems are addressed quickly.

Maintenance and repair are both important aspects of keeping equipment and machinery functioning properly. Maintenance involves regularly scheduled tasks, such as cleaning, lubricating, and inspecting equipment to prevent problems and extend its lifespan.

Repair, on the other hand, is necessary when equipment breaks or malfunctions and requires fixing or replacing parts. While maintenance can help prevent the need for repairs, it cannot completely eliminate the possibility of equipment failure. Both maintenance and repair require skilled technicians and can be costly, so it is important to prioritize preventative maintenance to minimize the need for repairs.

Identifying the Problem

Before attempting to fix a 3D printer, it is important to identify the problem. This can be done by running a test print, checking for any errors in the software, and inspecting the machine for any signs of damage. Once the source of the issue has been identified, you can then take steps to troubleshoot and resolve it.

Taking Safety Precautions

When working with 3D printers, safety is of utmost importance. It is important to wear protective eyewear and gloves when handling the machine, as well as taking the proper precautions when dealing with hot components. Additionally, make sure to unplug the printer before performing any repairs or maintenance.

Obtaining Materials & Tools

Once you have identified the problem, you will then need to obtain any materials and tools necessary for the repair or maintenance. Depending on the issue, this could include replacement parts, lubricants, cleaning solutions, and other items. You may also need specialized tools for certain repairs or maintenance tasks.

Executing the Repair

Once all the necessary materials and tools have been obtained, you can then begin to execute the repair or maintenance. This could include replacing a faulty part, tightening screws, cleaning and lubricating components, or performing other tasks as necessary. If you are unsure of how to proceed with the repair, it is best to consult an expert before attempting any complex repairs.

Testing

Once the repair or maintenance is complete, it is important to test the 3D printer to make sure that it is working properly. This can be done by running a test print or checking for any errors in the software. If everything seems to be functioning correctly, then you can begin using your 3D printer again as normal.

Fixing a 3D Printer That Won’t Turn On

If your 3D printer won’t turn on, the first thing to do is check the power cable and make sure it is securely connected to both the outlet and the machine. If it is, then you may need to replace a faulty part or investigate other possible causes of the issue. It is best to consult an expert if you are unable to diagnose the problem or don’t have the necessary tools or skills to fix it.

Troubleshooting Common Problems

3D Printers can experience a wide range of issues, from software glitches to hardware malfunctions. Fortunately, many of these problems can be identified and resolved with the right tools and knowledge. Here are some common issues and instructions on how to troubleshoot them:

Nozzle Clogs: If your nozzle is clogged, you may need to clean it with a wire brush or compressed air. You can also try using a cleaning solution designed specifically for clogged nozzles.

Filament Jam: If your filament is not feeding properly, you may need to check the tension of your spool and adjust it if necessary. You should also make sure that the filament is loaded correctly and that the feeder and drive gears are clean and free of debris.

Nozzle Leaks: If your nozzle is leaking, you may need to replace the O-rings or nozzle itself. You can also try cleaning the nozzle with a wire brush or a cleaning solution designed for 3D printers.