3d printing quoting software.

Are you tired of spending hours trying to get accurate quotes for your 3D printing projects? Do you find yourself unsure about which printing method to choose or how much it will cost?

As 3D printing becomes more popular in various industries from manufacturing to healthcare, it is important to have tools that make the process smoother and more efficient. One key aspect of the process is getting an accurate quote for the project at hand. In the past, this often meant contacting multiple vendors and waiting for responses. Luckily, with the advent of 3D printing quoting software, this process can now be streamlined.

If you’re in the market for 3D printing services, choosing the right software to get a quote can save you time, money, and headaches. In this article, we’ll explore the benefits of using 3D printing quoting software and some of the top options available in the market.

What is 3D Printing Quoting Software?

3D printing quoting software is a technology that helps businesses create accurate and competitive quotes for their 3D printing services. It automates the process of quoting 3D printing jobs, making it quick and easy to generate quotes for customers. The software can be used to calculate materials costs, labor costs, shipping costs, and turnaround times for orders.

It also allows businesses to customize each quote according to their customer’s specific needs, ensuring that they get the best deal possible. With this software, businesses can easily keep track of all quotes sent out and quickly respond to customer inquiries. By streamlining the quoting process with 3D printing quoting software, businesses can save time and money while providing excellent customer service.

Benefits of Using 3D Printing Quoting Software

Using 3D printing quoting software can provide numerous benefits for businesses. It can save valuable time by automating the process of creating quotes for customers, allowing businesses to focus their energy on other tasks. Additionally, it can help ensure accuracy and competitiveness when quoting jobs, as the software will accurately calculate material costs and turnaround times.

With this technology, businesses can easily keep track of all quotes sent out, allowing them to quickly respond to customer inquiries and provide excellent customer service. Finally, using 3D printing quoting software will help businesses stay organized and efficient while providing accurate quotes that are tailored to each customer’s needs. Overall, utilizing 3D printing quoting software is a great way for businesses to save time, money and resources while providing top-notch customer service.

Understanding the 3D Printing Process

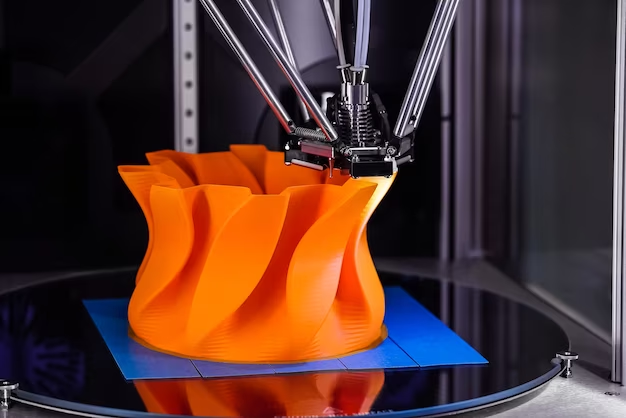

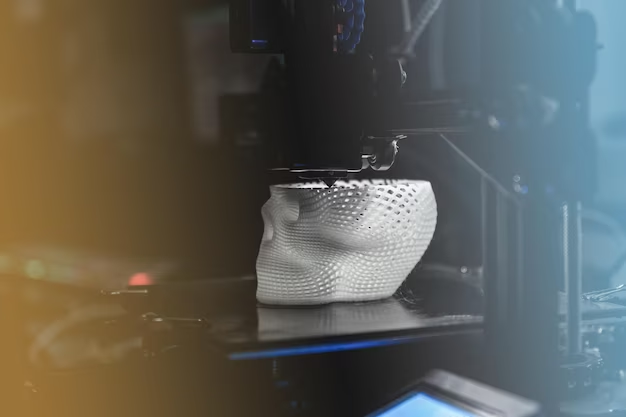

Understanding the 3D printing process is essential for businesses to get the most out of their 3D printing quoting software. The process begins with a 3D model, which can be created using CAD software or scanned from a physical object. This model then needs to be adjusted and prepared for the printer in order to ensure the best quality print.

Once prepared, the 3D printer will use a variety of materials such as plastics, metals, or ceramic to create the desired shape layer by layer. Finally, post-processing may be necessary to ensure an optimal finish. By understanding this process, businesses will have all of the information they need to accurately quote jobs and provide excellent customer service.

Types of 3D Printer Technologies

There are several different types of 3D printer technologies available, each offering unique benefits for various applications. Fused Filament Fabrication (FFF) is the most popular and widely used 3D printing technology. It works by extruding a fine filament of melted plastic onto a build plate to form the desired shape layer by layer.

On the other hand, Stereolithography (SLA) uses laser beams to cure liquid photopolymer resins into solid objects, resulting in superior surface quality compared to FFF. Material Jetting creates parts using droplets of polymer resin which are then cured with UV light. Finally, Selective Laser Sintering (SLS) employs high-powered lasers to melt powdered materials such as nylon and metal alloys into parts with strong mechanical properties and intricate details.

By understanding these technologies, businesses can make a more informed decision when selecting the right 3D printing technology for their needs.

Digital Models and File Types

Digital models are 3D files used to produce physical objects with a 3D printer. They can be created from scratch using CAD software or downloaded from existing libraries. STL is the most popular file type for 3D printing and it describes the geometry of an object with triangles, which the printer then uses to build the part layer by layer.

Additionally, there are other file formats used for specific types of printers such as OBJ for Material Jetting and SLS machines that require SLT files. These forms contain more details than STL files, but they may not always be compatible with all 3D printers. It’s important to check what format the printer requires before sending a model to print in order to minimize errors and maximize efficiency.

Wide Range of Materials Available for 3D Prints

The range of 3D printing materials is ever-expanding, and the possibilities are virtually endless. From thermoplastics like PLA and ABS to metal alloys such as stainless steel and aluminum, 3D printing technology can be used to create parts in a variety of materials suitable for different applications.

For example, nylon is an excellent choice for parts that require significant strength or flexibility, while polycarbonate is perfect for parts that need to be lightweight but sturdy. Additionally, exotic materials such as Carbon Fiber Reinforced Polymer (CFRP) can be used for high-performance parts that require greater strength than traditional plastics.

By using different materials with various properties, engineers have the ability to customize their designs to meet specific needs and requirements. With so many options available, 3D printing truly provides unlimited potential for creating unique objects from scratch!

Machine Time Required for Different Projects

The amount of time required to complete a 3D printing project varies depending on the size, complexity, and material of the part being made. For simple projects such as small plastic items, the machine time can be as little as 15 minutes. On the other hand, large scale projects with complex geometries or multiple colors may take several hours to print.

Additionally, certain materials may require additional setup time due to their unique properties. For example, metal alloys require extra steps for preheating and post-processing before they are ready for use. Depending on the scope of the project, it may also take longer to create if multiple machines are needed for specific tasks. Ultimately, the amount of machine time required for any given project depends on its size, complexity, and desired material.

Cost of 3D Printing Services Vary Greatly Depending On the Project

The cost of 3D printing services can vary greatly depending on the size, complexity, and material of the project. For simple items such as small plastic parts, it may only cost a few dollars to print them. On the other hand, larger projects with complex geometries or multiple colors could run hundreds or even thousands of dollars.

Additionally, certain materials may require additional setup time due to their unique properties, which can add to the total cost. For example, metal alloys are often more expensive to print due to preheating and post-processing steps that must be taken before they are ready for use.

Depending on the scope of the project and the desired outcome, costs may fluctuate further if multiple machines are needed for specific tasks. Ultimately, when considering 3D printing services it is important to consider all aspects of the project in order to get an accurate quote for its completion.

Common Challenges Inherent in the 3D Printing Process

The 3D printing process is an exciting and innovative way to produce objects, but it is not without its challenges. One of the most common issues is achieving a consistent print quality across multiple prints. This can be difficult to achieve due to factors such as filament feeding rate, nozzle temperature, and layer height that all need to be closely monitored and adjusted if necessary.

Additionally, some materials can be more challenging than others when it comes to achieving a successful print. For example, flexible filaments require special care when printing in order to avoid warping or deformation of the object due to the material’s low melting point.

Finally, overhangs and bridging can also cause difficulty for 3D printers, as these features require additional support structures in order for them to be printed properly. With careful consideration of these challenges during the design phase, however, one can greatly improve their chances of producing successful 3D prints with little hassle.