What are 3d printed dentures?

Have you ever heard of 3D printed dentures? It may sound like something out of a sci-fi movie, but this technology is becoming increasingly popular in the dental industry.

Dentures have been around for centuries, but the process of making them has remained relatively unchanged. Traditional dentures are formed by taking a mold of the patient’s mouth, which can be uncomfortable and time-consuming. However, with the advent of 3D printing technology, dentures can now be created in a more efficient and precise manner.

3D printed dentures are a game-changer in the dental industry. They offer numerous benefits such as improved fit, reduced production time, and lower costs. In this article, we’ll explore what 3D printed dentures are, how they are made, and why they are becoming an increasingly popular option for those in need of dentures.

What are 3d printed dentures?

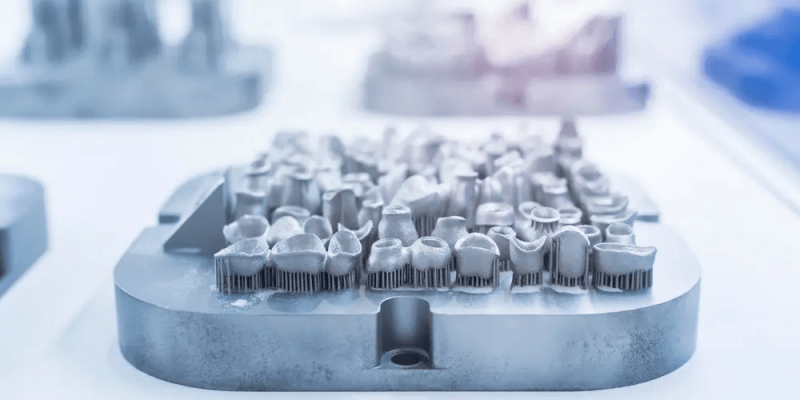

3D printed dentures are quickly becoming one of the most revolutionary advancements in modern dental care. 3D printing is an incredibly versatile technology, making it perfect for designing and manufacturing custom-fit dentures. This form of digital denture technology significantly reduces costs compared to traditional methods, and the speed at which they can be made increases throughputs, meaning that the patient gets a much faster turnaround on their new dentures. Furthermore, 3D printed dentures offer increased design options that can produce higher quality results than traditional methods warrant.

When considering making the switch to 3D printing your dentures, there are many advantages to consider. One of them is affordability – savings up to 80% have been reported with 3D printing compared to conventional techniques. Additionally, instead of using a range or mono-designs as traditionally done in laboratories all over the world, creating custom designs become possible now with 3D printing technology. Different tooth colours and saturation levels as well as various shapes and sizes, all this can be easily achieved due to its digital nature; materials like acrylate resins make great frames while combining natural feel and durability in one package! Finally accuracy also gets a boost when producing digitally; With layer heights ranging from 2-

Another major advantage that 3D printed dentures offer is their improved fit. Due to the precise nature of the technology, dentures made with 3D printing are much more accurate than traditional methods and fit more comfortably in the patient’s mouth. Furthermore, they don’t require lengthy preparation time and can be produced quickly, allowing the patient to receive their new dentures sooner than ever before.

Benefits of 3d printing dentures

Using 3D printing to create dentures has clear advantages over traditional denture-making methods. 3D printing is incredibly precise, allowing dental professionals to generate dentures that fit the patient’s mouth precisely and comfortably. This means no additional time or money have to be spent on making adjustments after delivery of the denture. 3D printing also allows for lighter, more durable materials such as medical-grade plastic to be used in the creation of the denture, ensuring it lasts longer and its form remains intact even after several years of use.

Additionally, 3D printed dentures can be manufactured fairly quickly compared to other types. The turnaround time for a full set (both upper and lower) of personalized 3D printed Dentures might range between four days to two weeks depending on the complexity of the case. This makes them ideal for those who need an immediate solution since having no teeth can affect someone’s speech, confidence and overall well being. Lastly, utilizing this technology is also good for the environment since it generates less waste than when done traditionally due to lower friction rates in production meaning fewer raw materials being used from start to finish.

High-quality prostheses

3D printing has revolutionized digital production of dentures, offering significantly increased production with lowered prices and higher standards of quality control. Carbon’s state-of-the-art printers offer a versatile solution that can provide a multitude of shades, highly accurate results, and enhanced physical properties such as color stability and high impact fracture resistance. The superior accuracy and aesthetics are well received by medical professionals and patients alike, making high-quality prostheses more accessible than ever before.

The capability to fully print denture bases and teeth enables labs to take full advantage of the latest advancements in 3D printing technology for creating the most realistic and comfortable prostheses possible. Carded teeth are also available for those seeking greater diversity in tooth shape or form, ensuring customers never have to feel like they are sacrificing quality for their budget. Whatever the choice, thanks to 3D printing technology from Carbon, high-quality prostheses can now be reliably produced faster and cheaper than ever before.

Reduce reliance on skilled artisans

The use of 3D printing technology has revolutionized the production of dentures. This has allowed dental labs and technicians to produce dentures with significantly less labor hours, far more quickly and efficiently than before. By reducing the amount of manual labor involved in fabrication, 3D printing has helped reduce reliance on highly skilled artisans that are becoming harder to find.

In comparison to traditional methods, 3D printing can cut labor hours by around half for the same number of dentures. Additionally, this technology makes it much simpler for lab owners and technicians to rapidly expand production without having to search out additional skilled technicians. This greater efficiency is aided further by facilities such as automated grinding or milling machines that can polish finished products very quickly. Ultimately, these pioneering technologies enable dental labs to meet the demand in an increasingly competitive market while leveraging the most modern techniques available.

Better fit

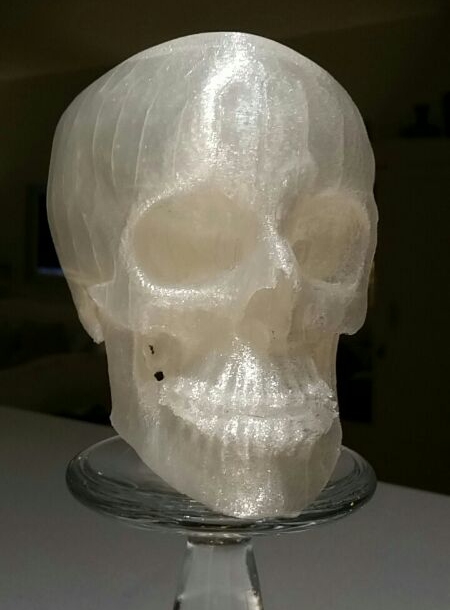

Digital denture workflows have revolutionized the process of fitting dentures, making it faster and more precise. Faster still is the even more advanced workflow that uses a patient’s existing denture as a custom tray to create an accurate VPS (Vinyl Polysiloxane Impression) impression. This impression can then be scanned using an intraoral scanner and sent to the lab where the new denture can be digitally designed using denture CAD software and then 3D printed. Eliminating the need for stone and wax used in traditional methods, this innovative breakthrough has reduced the number of appointments needed to complete and deliver a new denture from five to just two – resulting in improved fit, comfort, and increased accuracy. This reference impression method significantly reduces any potential copy errors, meaning that better-fitting dentures can be produced with greater speed and efficiency. Improved workflows such as these have made having digital dentures quicker and easier than ever before – improving the overall quality of care provided to patients.

Improve profits

Dental labs now have the ability to increase profitability with 3D printing by moving away from traditional manufacturing methods for dentures. With 3D printing, monotonous manual labor is reduced and costs are cut down significantly. For example, switching to a 3D printing workflow can save an hour or more of manual labor per arch and up to $50 in material cost per arch. When this is applied over multiple dentures in a day it adds up to tens of thousands of dollars in savings per year. Furthermore, high-speed 3D printers like Carbon’s M2 can further speed up the production process allowing labs to create highly accurate dentures at a fraction of the time compared to conventional methods while drastically reducing post-processing time and cost. All these factors combined make it possible for dental labs to scale their denture business and improve profits.

Easily replaceable

With the advent of digital dentures, patients no longer need to worry about the hassle of replacement and repair in the event that they lose or damage their dentures. Traditional dentures require multiple appointments with technicians and lots of impression work before new dentures can be made. Digital denture technology offers an alternative solution, making replacing lost or broken dentures much more convenient for patients.

Thanks to digital dentures, lost or damaged dentures are easily replaceable since a digital copy is stored at a lab. This means a lab can reprint the same set of missing teeth quickly and conveniently so that patients don’t have to wait for appointments or live without their prosthetics for extended periods of time. The ease and speed of replacement makes digital denture technology a great option for many people looking to replace their traditional full or partial denture sets.

When to choose 3d printed dentures?

3D printed dentures are quickly growing in popularity as an effective and often more cost-efficient method of manufacturing high-quality dentures. This innovative and versatile digital denture production technique offers labs a myriad of advantages, especially when compared with traditional methods. For instance, those who seek to increase their production volumes or reduce the labor needed for manufacturing will likely find 3D printing to be an efficient option. Likewise, those who may currently be unable to hire the skilled technicians necessary for traditional fabrication processes can benefit from 3D printing’s automated system, which requires far less human labor and intervention.

Additionally, choosing 3D printed dentures can provide labs with a premium and economy option that evens out costs while ultimate delivering superior results in terms of accuracy, consistency, and convenience. With greater precision than ever before, fabrication labs now have the capability to produce dentures quickly and accurately without compromising on quality or safety standards. This ultimately gives patients secure, comfortable fitting prostheses that represent excellent value for money whilst providing optimum function and aesthetics. Choosing 3D printed dentures can help any dental lab to heighten its success in this growing market space while optimizing costs at the same time.