Do you need a computer to 3d print?

If you are new to the world of 3D printing, you may be wondering whether you need a computer to get started. After all, 3D printing sounds like a complex process that requires a lot of technology. But do you really need a computer to 3D print?

3D printing has become increasingly popular in recent years, and for good reason. With the ability to create custom objects from digital designs, it has revolutionized the way we approach manufacturing and crafting. However, many people are still unsure about the technology and what it takes to get started.

The answer to whether you need a computer to 3D print depends on a few factors. While a computer is not always necessary, it is still a critical component for most 3D printing projects. In this article, we will explore the different scenarios where a computer may or may not be required, as well as the software options available for those without a computer. So, whether you’re an experienced 3D printing enthusiast or just getting started, read on to learn everything you need to know about using a computer for 3D printing.

Do you need a computer to 3D print?

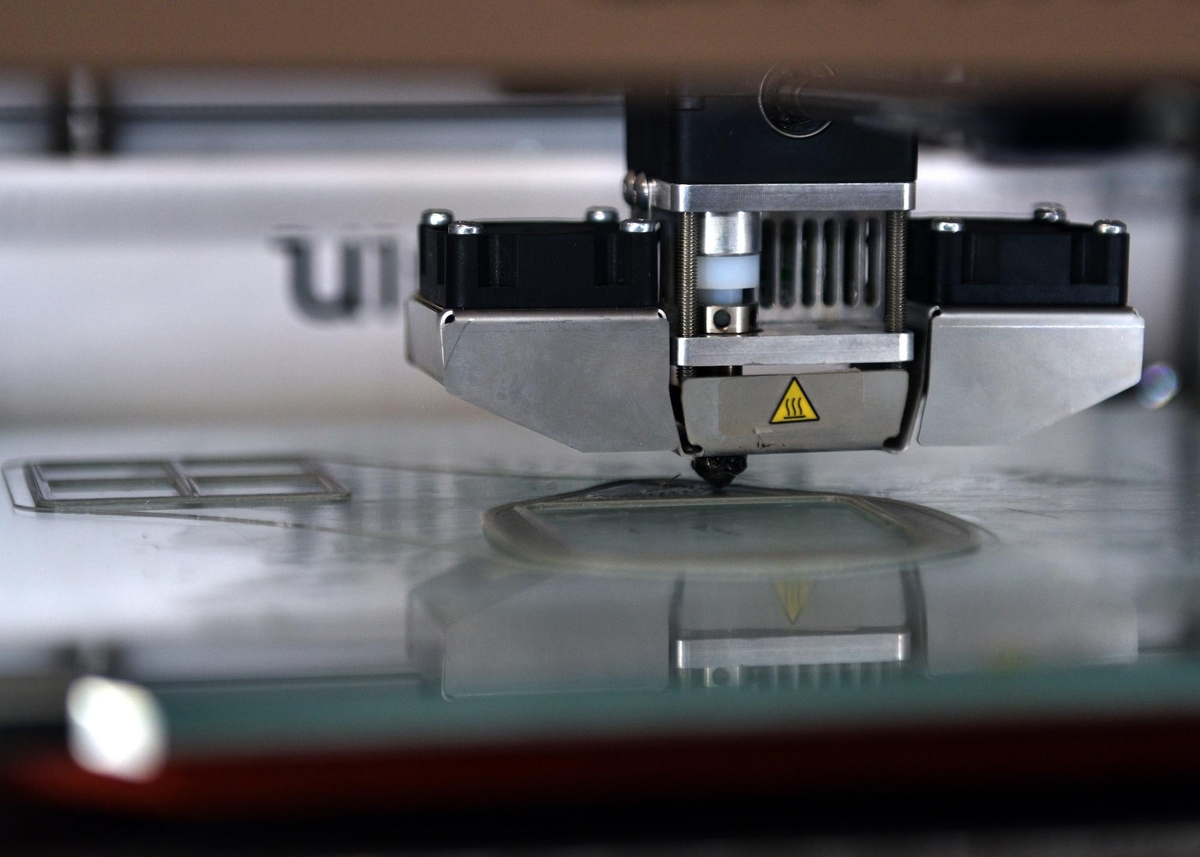

It depends on the type of 3D printing project you have in mind. For basic projects, such as small plastic parts or figurines, it is possible to use a standalone 3D printer without a computer. This can be a great option for those who are just getting started with 3D printing and want to experiment with the technology. However, using a computer provides many advantages such as allowing you to create complex designs, adjust settings and access a wide range of materials.

If you plan to use a computer for 3D printing, there are a few things you should consider. The first is the type of software you will need. Most 3D printing projects require specialized software such as Fusion 360 or Cura. These programs allow users to design and manipulate objects in three dimensions before they are 3D printed. Additionally, most 3D printers come with their own software that helps you connect and control the printer from your computer.

What computer do I need for a 3D printer?

When researching the specs needed for your computer to use a 3D printer and make or print 3D print designs, it is important to consider what software you will be using and their system requirements. Cura is one of the most popular software packages out there when it comes to sending 3D prints to your 3D printer, so it is wise to make sure your computer meets the minimum system requirements. According to our research, you need at least 2GB of RAM, 50MB of available hard drive space, and a Dual Core processor with 2GHz frequency or better. Additionally, you will need an OpenGL 2.0 capable video card with 256MB of RAM that supports non-packed pixel formats. Your computer should also support 1024 x 768 screen resolution as well GPT partitions larger than 2TB and USB or RS232 port connectivity.

These necessary requirements will ensure that your 3D printing experience runs smoothly and efficiently without any lagging or crashing due to incompatibility with the necessary software. While you do not necessarily need the most state-of-the-art machine for a good quality experience with 3D printing, having a sturdy system that meets these basic requirements can help prevent additional frustration down the line as you become more advanced in your 3D printing projects.

What is required for 3D printing?

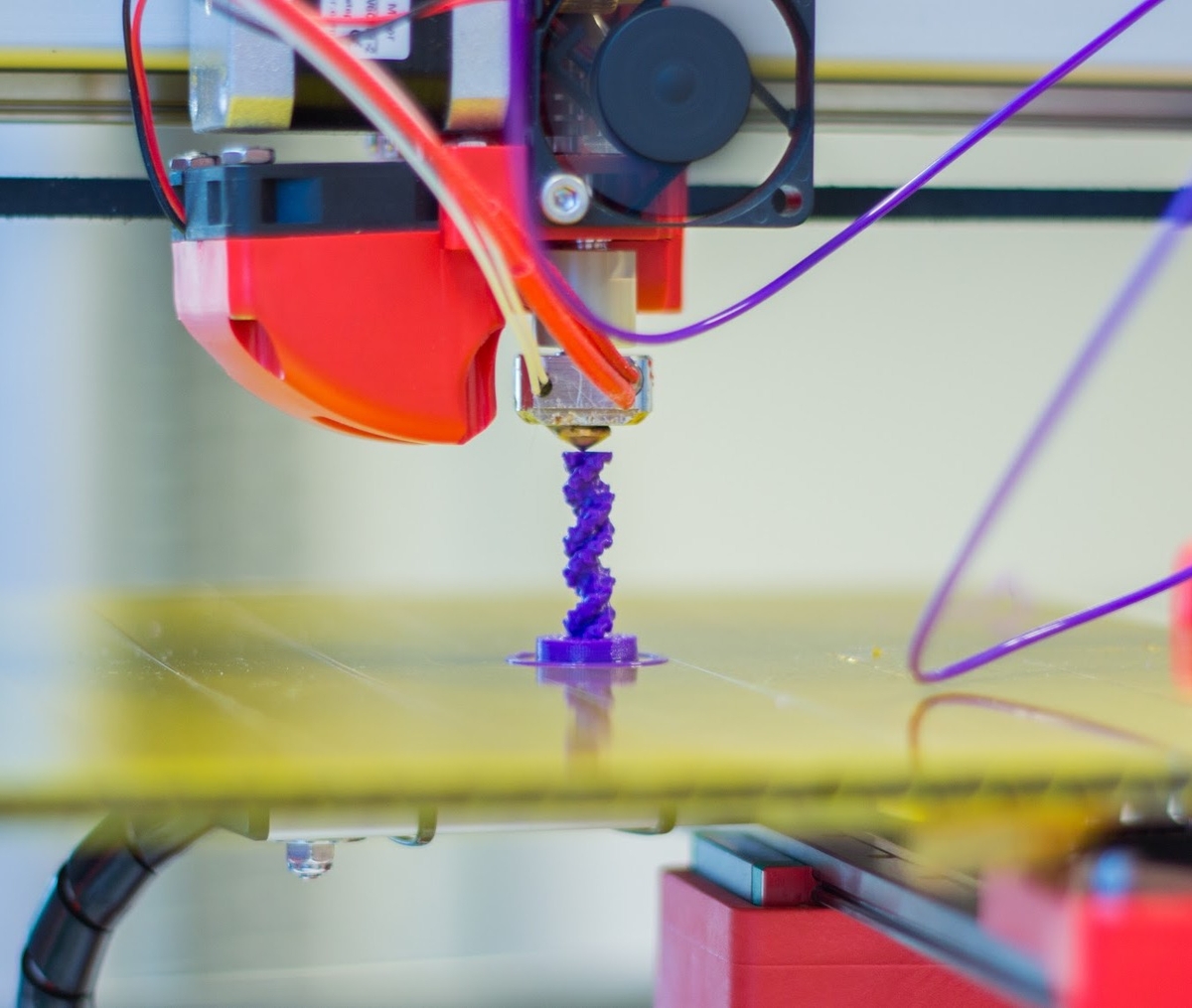

Creating 3D printed objects requires more than just a 3D printer – you also need filament, software, and a computer. A 3D printer, such as the Ender 3 from Amazon, is essential for printing physical copies of designs. Filament is what the 3D printer uses to create the object, and it comes in a range of materials, allowing for different levels of durability or flexibility. Not all printers come with filament included, so it is important to purchase additional filament when starting out with 3D printing.

A computer is also required for transferring file designs to your 3D printer, as well as free software to create them or prepare them for printing. Some of these programs are open source program and accessible at no cost online. Popular examples include Cura and Simplify3D (both available on Amazon). With these user-friendly programs, anyone can begin designing their own projects that come to life in tangible form through the process of 3D printing!

Do 3D printers come with design software?

3D printers are becoming increasingly popular, but they don’t come with the design software you’ll need to create or manipulate printable models. Instead, you’ll have to download free programs like a slicer and a CAD software in order to make your own designs. A slicer will take you user created design file, whether it be an STL model or something more complex, and convert it into code that your 3d printer can understand. The most popular slicer these days is Cura; however, other choices such as Slic3r and Skeinforge also exist.

In addition to the slicing software, you’ll need something a bit more complex to actually design a 3d print. Popular pieces of software used include Blender and Sculptris from Pixologic which offer excellent printing capabilities. Some websites like Thingiverse even provide thousands of free 3d designs that one can download and simply warm up their printer for! No copyright laws apply here since all of the authors on Thingiverse willingly share their content for others to benefit from – so feel free to browse around and print whatever tickles your fancy!

Is 3D printing hard to learn?

Learning 3D printing can seem like a daunting task in the beginning, especially with all of the different options and features that can be used. While getting your 3D printer up and running may be relatively simple, designing or creating your own projects is much more difficult to learn. Complex software such as Fusion 360 can provide an array of options when it comes to customizing your design, which may take some time to understand and deploy effectively.

Navigating through the feature-laden software options certainly has its challenges, but with dedication and practice you will easily become familiarized with them. It may take a bit longer for more complex designs, but once you’ve learned the ins-and-outs of 3D printing, navigating through the different menus should become second nature– giving you the ability to quickly design something without struggling too much. No matter how daunting learning 3D printing may seem at first glance – don’t give up because eventually you will reap its rewards.

What is the easiest 3D software to learn?

TinkerCad is the easiest 3d software to learn due to its user-friendly interface and accessible tutorials. It’s designed for kids, but the setup is intuitive enough for adults as well. The learning curve with TinkerCad is gentle and has a great set of tutorials; however if you have acquired a handle on the concepts and would like to delve in further, Fusion 360 or Onshape are great options to explore.

Fusion 360 and Onshape are more suitable for professionals since they offer greater features and require more intricate knowledge. These software are used by people employed in various industries as they involve intricate designing such as electronics engineering, architects/construction and more. With either of these two, users can easily build complex polygonal models, manipulate shapes via tools like booleans operations, extrude meshes into solid geometry etc.

How long does it take to print something on a 3D printer?

3D printing technology has revolutionized the way products are made, with objects being designed and manufactured quickly with precise details. With 3D printing, it is possible to produce intricate pieces without the need for traditional methods of production that often require large scale machinery. However, most people have one question in mind: How long does it take to print something on a 3D printer?

The answer depends largely on the size and complexity of what you want to print. A small 3D print typically takes about 30 minutes, but larger more detailed prints will require considerably more time. For example, a hobby-level 3D printer may produce prints that take 6 hours or less while complex designs might take as long as 7 days! One major factor impacting time is how much fine detail the design has – if there are lots of minute features then the printer’s arm needs to constantly move back and forth across parts of the object, adding small amounts of resin each time. In some cases shrinking an oversized or intricate object before printing can help reduce print times drastically. With larger printers featuring multiple working arms and faster technologies like stereolithography (SLA), these wait times can come down even further.