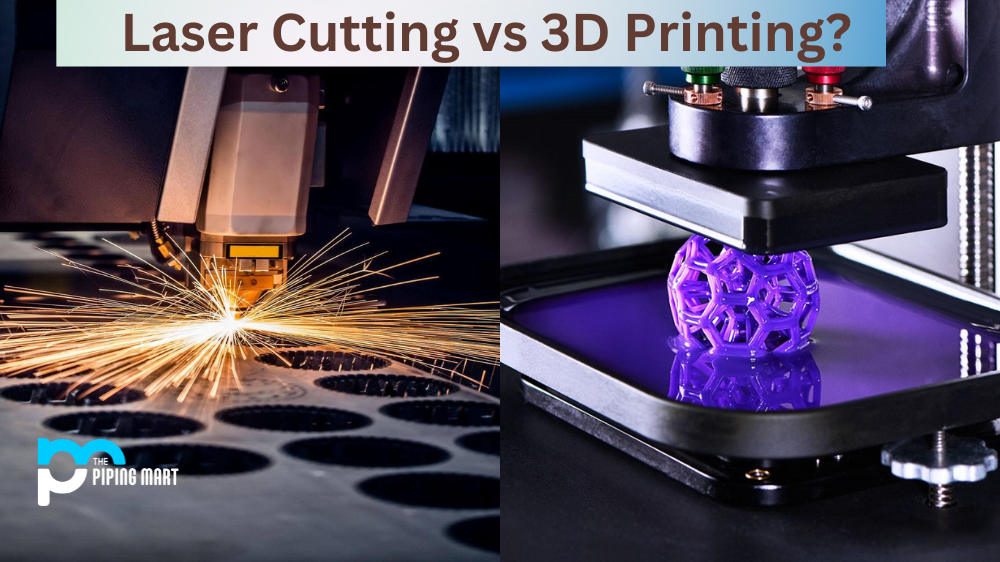

3d printing vs laser cutting

When it comes to manufacturing, there are a lot of options available. Two popular choices are 3D printing and laser cutting. But which one is better? Which one should you choose?

Both 3D printing and laser cutting are modern and innovative techniques that have revolutionized manufacturing. They have made it easier, faster, and more cost-effective to create complex designs and prototypes. However, each method has its own strengths and weaknesses.

If you are in the manufacturing industry, it’s important to know the differences between 3D printing and laser cutting. Knowing which one to use can save you time, money, and effort. In this article, we will compare and contrast these two methods, highlighting their pros and cons, to help you make an informed decision.

While both methods have their advantages and disadvantages, the decision ultimately depends on the specific needs of your project. In this article, we’ll compare 3D printing and laser cutting in terms of cost, speed, accuracy, and material compatibility to help you determine which method is best for your manufacturing needs.

What Is a Laser Cutter?

A laser cutter is a machine that uses a focused beam of light to cut through materials. It works by melting, burning, or vaporizing the material along a programmed path. Laser cutters are highly accurate and can typically cut materials within 0.1mm of the desired shape or design. They can also cut complex shapes with ease and make detailed cuts into hard materials like metals and plastics.

One major advantage of laser cutting is that it offers precise and detailed cuts. By using a computer-controlled laser beam, the machine can accurately cut complex shapes and designs with high precision. Laser cutting also does not require any contact with the material, meaning that there is no risk of damaging or marring the surface. Additionally, since the process does not require physical contact with the material, there is less wear and tear on the machine itself.

What Is 3D Printing?

3D printing is a manufacturing process that involves building up three-dimensional objects layer by layer. Unlike traditional machining techniques, 3D printing does not require any physical contact with the material, making it suitable for delicate materials and designs. It also offers high architectural freedom and can produce complex shapes with ease .

3D printing is highly accurate and can produce detailed designs with relatively few limitations. It is also extremely fast; in most cases, the entire process can be completed within a few hours depending on the size of the object.

3D printing is a process of creating three-dimensional objects by using a computer-aided design (CAD) model. The printer reads the digital model and then builds the object layer by layer using various materials such as plastic, metal, or even food.

This technology has revolutionized the manufacturing industry by allowing for faster production times and customization of products. It has also led to advancements in fields such as medicine and aerospace, where 3D printing is used to create prosthetics and airplane parts, respectively. With its versatility and potential for innovation, 3D printing has become an important tool for businesses and individuals alike.

Materials Used in 3D Printers Vs Laser Cutters

3D printing and laser cutting can both be used with a variety of materials, but there are some significant differences between the two processes. 3D printers typically work best with thermoplastics like ABS or PLA, while laser cutters are most suitable for softer materials like wood, paper, leather, or fabric. Metal can also be cut with a laser cutter, but it is not as precise as 3D printing.

Materials used in 3D printers and laser cutters differ significantly. 3D printers use a variety of materials such as plastics, metals, ceramics, and even food products. These materials are melted and then extruded layer by layer to create a 3D object.

On the other hand, laser cutters use materials that can be cut or etched such as wood, plastic, paper, fabric, and leather. The laser beam cuts through the material, creating precise and intricate designs. While 3D printers are better suited for creating complex 3D shapes, laser cutters are ideal for cutting and engraving flat materials. The choice of material ultimately depends on the intended use and desired outcome of the project.

Cost Comparison Between 3D Printing and Laser Cutting

The cost of 3D printing and laser cutting can vary depending on the material, complexity of the design, and other factors. On average, laser cutting is more affordable than 3D printing.

However, it should be noted that 3D printing offers higher accuracy and more architectural freedom than laser cutting. Therefore, if you require a more complex or intricate design, 3D printing may be the more cost-effective option.

When it comes to cost comparison between 3D printing and laser cutting, it depends on the specific project and the materials being used. Generally, 3D printing can be more expensive upfront because of the cost of the printer and the materials, but it can be more cost-effective for producing small, intricate designs in low volumes. Laser cutting, on the other hand, can be more cost-effective for larger volumes and for cutting through thicker materials.

Additionally, laser cutting can be quicker and more precise than 3D printing in certain applications. Ultimately, it is important to consider the specific needs of the project and to weigh the costs and benefits of each method before making a decision.

When to Choose a Laser Cutter Vs 3D Printer?

When deciding between laser cutting and 3D printing, it is important to consider the specific needs of your project.

If you need a fast and cost-effective solution for creating detailed shapes or designs in softer materials like wood, paper, leather, or fabric, then laser cutting may be the best option. On the other hand, if you require a more complex design with higher accuracy in thermop lastics or metals, then 3D printing may be the better choice.

When to Choose a Laser Cutter Vs 3D Printer

When it comes to deciding between a laser cutter and 3D printer for your project, the decision ultimately depends on the specific needs of your project.

Laser cutters are ideal for projects that require fast and cost-effective solutions in softer materials like wood, paper, leather, or fabric. On the other hand, 3D printing offers higher accuracy and more architectural freedom than laser cutting and is better suited for projects requiring intricate designs in thermoplastics or metals.

What kind of projects is it possible to create with laser cutting?

Laser cutters can be used to create a wide range of projects, from simple shapes to complex designs. Laser cutting is ideal for creating detailed pieces that require precision and accuracy, such as jewelry or intricate art.

It can also be used for industrial purposes, such as laser-cutting metal parts for cars or other machines. Laser cutting is also commonly used in the production of consumer goods like toys, furniture, and signs.

Quality and Precision

When it comes to precision, accuracy, and quality of work, 3D printing and laser cutting each have their advantages and disadvantages. 3D printing offers higher accuracy, which makes it ideal for complex designs that require exact measurements. Laser cutting is known for its high precisionand can be used to create intricate shapes with minimal waste material. However, laser cutting requires a very precise setup and is more expensive than 3D printing.