What is rapid 3d printing?

Have you heard of rapid 3D printing? It’s a revolutionary technology that’s changing the way we manufacture products. But what exactly is it, and how does it work?

3D printing has been around for decades, but it wasn’t until recently that it became accessible to the masses. With rapid 3D printing, the process has become even faster and more efficient, allowing for the creation of complex designs in a matter of hours.

3D printing has been around for decades, but rapid 3D printing is a relatively new development. It’s a process that allows for quick and cost-effective production of complex parts and prototypes. This technology has been a game-changer for industries such as aerospace, automotive, and healthcare.

If you’re curious about rapid 3D printing and how it can benefit your business, this article will provide you with an overview of the technology and its applications. We’ll dive into the details of how it works, the benefits it offers, and the industries that are using it to their advantage. So, let’s get started!

In this article, we’ll take a closer look at what rapid 3D printing is and how it’s being used in various industries. From healthcare to aerospace, this technology is transforming the way we think about manufacturing. So if you’re curious about the future of production, read on to learn more about rapid 3D printing.

What is rapid 3d printing?

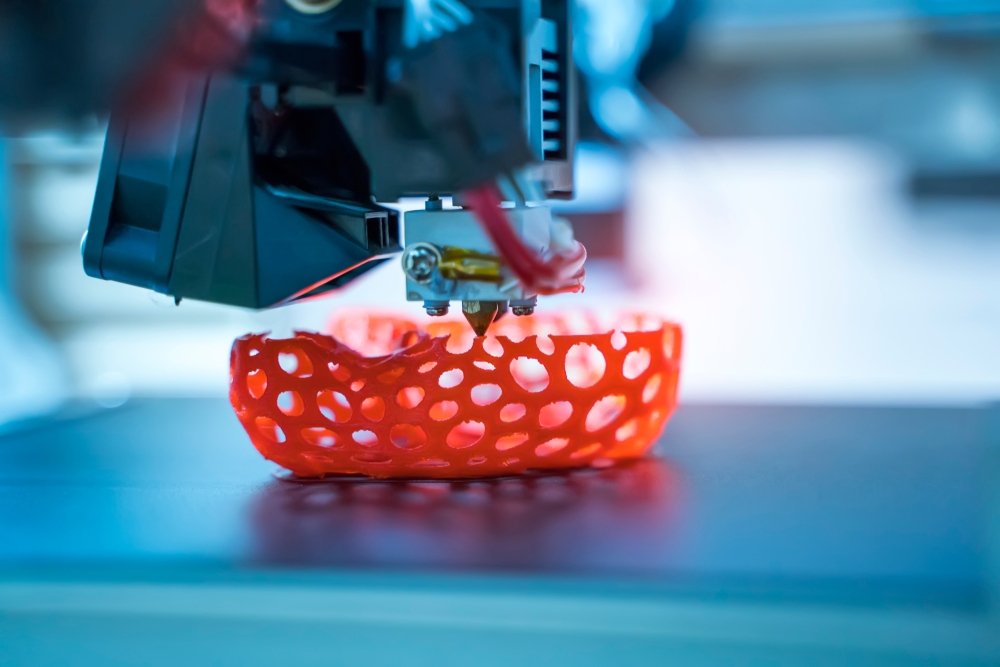

Rapid 3D printing is an advanced manufacturing technology that enables the production of complex parts and prototypes in a matter of hours. It works by taking a digital 3D model and converting it into physical parts or models through an additive layer-by-layer process.

This method is much faster than traditional methods, like injection molding, as it does not require expensive tooling or lengthy setup times. Additionally, it is a much more efficient and cost-effective way to produce small batches of parts or prototypes.

Rapid 3D printing is being used in a variety of industries, including healthcare, automotive, aerospace and more. In the medical field, it allows for the rapid production of implants and prosthetics to help improve patient outcomes. In the automotive industry, this technology enables manufacturers to quickly build working prototypes for testing, reducing development times. In aerospace engineering, rapid 3D printing helps engineers create complex parts quickly and cost-effectively.

Rapid 3D printing is a revolutionary technology that is transforming the way we manufacture products. It has allowed for faster prototyping, shorter lead times, and more efficient production processes in a variety of industries. With this technology, businesses can produce complex parts or models quickly and cost-effectively, allowing them to stay ahead of the competition.

What is Rapid Prototyping?

Rapid prototyping is an important part of the rapid 3D printing process. It involves creating a physical model or prototype of a design quickly and cost-effectively.

This method can be used to test out different concepts, find design flaws, and make necessary changes before producing the final product. Rapid prototyping works by taking a 3D digital model and converting it into a physical model or prototype through an additive layer-by-layer process.

Rapid prototyping is used in a variety of industries, including automotive, aerospace, and healthcare. It allows engineers and designers to quickly test out different concepts and make necessary changes before committing to the final design. This helps reduce development times and costs for businesses, allowing them to stay ahead of the competition.

Is Rapid Prototyping the Same as 3D Printing?

The short answer is no. While rapid prototyping and 3D printing are both additive manufacturing processes, they are not the same. Rapid prototyping is a specific type of 3D printing that focuses on quickly and cost-effectively creating physical models or prototypes of digital designs. This process allows engineers and designers to quickly test out different concepts and make necessary changes before committing to the final design.

On the other hand, 3D printing is a general additive manufacturing process that can be used to produce parts or products. This process uses a digital 3D model and converts it into physical parts or models through an additive layer-by-layer process.

The takeaway here is that rapid prototyping is a specific type of 3D printing that focuses on prototyping and testing, while 3D printing is a more general process used to create parts or products.

Rapid 3D printing has a variety of applications in many industries, ranging from automotive and aerospace to healthcare and consumer electronics. For example, in the automotive sector, this technology allows for faster prototyping of parts and components to reduce development time. In healthcare, it enables the rapid production of implants and prosthetics to improve patient outcomes. Additionally, consumer electronics companies can use it to quickly produce small parts or components that would otherwise be difficult and costly to manufacture.

Benefits of Rapid Prototyping

Rapid prototyping and 3D printing offer a number of benefits, including:

• Faster lead times – Rapid prototyping allows for the rapid production of parts or models, reducing development time.

• Cost savings – Since no tooling is required, there are significant cost savings associated with rapid prototyping.

• Complex designs – This technology enables the production of complex parts that would otherwise be difficult or impossible to manufacture using traditional techniques.

• Greater design flexibility – It allows for greater design flexibility since engineers and designers can quickly test out different concepts and make necessary changes before committing to the final design.

Overall, rapid 3D printing is a revolutionary technology that has revolutionized the way companies manufacture products. It has enabled faster lead times, cost savings, and greater design flexibility, all of which have helped businesses stay competitive in a global marketplace.

How to Use Rapid Prototyping in Your Engineering Process?

The use of rapid prototyping can be an invaluable asset to any engineering or manufacturing process. Rapid 3D printing enables the quick production of parts and components, allowing engineers and designers to quickly test out different concepts and make necessary changes before committing to the final design.

By utilizing this technology, companies are able to reduce development times and costs while staying ahead of the competition.

There are several ways to use rapid prototyping in the engineering process. Firstly, companies can use it for initial testing and validation of digital designs. This helps to reduce development time by quickly determining whether a design is viable or not. Secondly, it can be used for product verification and validation prior to production. Lastly, it can also be used to create one-off custom parts or components that would otherwise be difficult or impossible to manufacture using traditional techniques.

Rapid 3D printing is an invaluable asset to any engineering or manufacturing process, as it enables faster lead times, cost savings, and greater design flexibility. By utilizing this technology, companies are able to remain competitive in a global marketplace while creating higher quality products at lower costs.

How Can I Get Started with Rapid Prototyping?

Getting started with rapid prototyping is simpler than you might think. The first step is to select the appropriate 3D printing technology for the project at hand. Depending on the project, some technologies may be more suitable than others. Once decided upon, the next step is to create a 3D model of your desired product or part in software such as Autodesk Fusion 360 or Solidworks.

Once the 3D model is complete, the next step is to prepare a file for 3D printing. This includes slicing the model into layers, adding supports if necessary, and setting up the printer settings. Finally, the file needs to be sent to a 3D printer for fabrication.