Why won’t my 3d printer print.?

Have you ever experienced the frustration of firing up your 3D printer only to find that it won’t print? It’s a common problem faced by 3D printing enthusiasts, and it can be a frustrating one, especially when you have a project to complete or deadline to meet.

3D printing has come a long way in recent years, and it’s no surprise that more and more people are adopting this technology for various practical and artistic applications. However, even with the most advanced 3D printers, things can go wrong, and it’s not always easy to know what’s causing the problem.

So, why won’t your 3D printer print? From issues with the filament to software glitches and hardware faults, there are several reasons why your printer may be misbehaving. In this article, we’ll explore some of the common reasons why 3D printers won’t print, and we’ll provide some tips on how to troubleshoot the issue and get your printer up and running again.

What is 3D Printing?

3D printing is a form of additive manufacturing technology where a three-dimensional object is created by laying down successive layers of material. 3D printing is also known as additive manufacturing, rapid prototyping, and direct digital manufacturing.

It has been used in many industries such as automotive, aerospace, and medical devices to create complex objects quickly and inexpensively. 3D printing works by adding layer upon layer of material (usually plastic) until the desired shape and structure have been achieved. The printer then heats up the material and controls its extrusion to create the object.

This process can be very precise and allow for intricate details that would be impossible to achieve using traditional methods. 3D printing can be used to produce detailed parts with high accuracy at a fraction of the cost compared to other traditional manufacturing methods such as machining or injection moulding.

Common Issues with 3D Printing

The process of 3D printing can be complex and having a successful print can often rely on many factors. Common issues that arise while 3D printing include inaccurate or incomplete prints, poor layer adhesion, warping or curling of the plastic, and clogged extruder nozzles. Inaccurate or incomplete prints can occur if the printer is not calibrated properly.

Poor layer adhesion may happen if the temperature settings are too low, which can cause the layers to not adhere to each other correctly. Warping or curling of plastic occurs when the plastic cools too quickly as it is being printed, causing distortion in the shape of the object. Clogged extruder nozzles can be caused by dirt accumulation in the nozzle due to improper maintenance or expired filament material.

Additionally, running out of filament during a print will result in an incomplete object as well. To avoid these common issues with 3D printing, it is important to keep your printer well maintained and ensure that you have enough material for each print job.

Materials

Materials are the building blocks of 3D printing and they play an important role in ensuring successful prints. There is a wide range of materials available for 3D printing, including plastics like ABS and PLA, metals such as stainless steel and titanium, and resins such as photopolymers. Each material has its own unique properties that make it suitable for certain applications.

For example, ABS is strong and flexible, making it ideal for structural parts; PLA is a biodegradable plastic that produces less odour during printing; and stainless steel is corrosion resistant and durable.

Different materials also require different temperature settings to ensure proper adhesion between layers, so it’s important to use the correct type of filament for each print job. Proper maintenance of your printer will help you get the most out of your materials and ensure that each print comes out looking great!

Printer Manufacturer

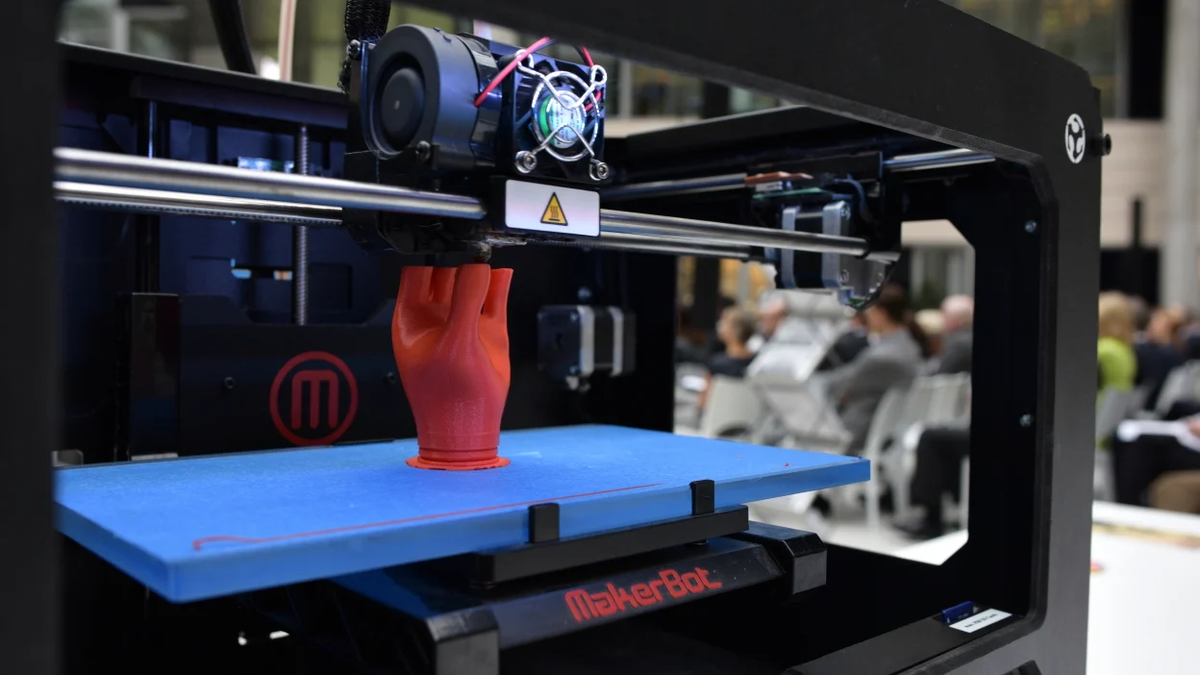

Printer manufacturers are responsible for the production and design of 3D printers. Companies such as Stratasys, Ultimaker, and MakerBot have become industry leaders in 3D printing technology. Their printers offer a range of features, from dual extruders to large build volumes and multiple materials support.

By developing innovative technologies, these companies provide users with reliable tools that can produce high-quality prints. Printer manufacturers also offer technical support services to help users overcome any challenges they may encounter during the printing process.

From installation assistance to troubleshooting tips, these companies strive to make 3D printing easier and more accessible to everyone. With their dedication to innovation and customer service, printer manufacturers are setting the standard for 3D printing technology.

Filament Manufacturer

Filament manufacturers play an important role in the 3D printing industry. They produce the materials used to create 3D objects, such as plastic, metal, and wood. Companies like ColorFabb, Polymaker, and eSun specialise in providing high-quality filaments for all types of printers.

These companies use advanced manufacturing techniques to ensure that their products are strong, durable, and reliable. With a wide variety of colours and materials available from these companies, users can easily find the perfect material for their 3D printing projects. Filament manufacturers also offer technical support services to help users find the right filament for their needs.

By collaborating with printer manufacturers and providing ongoing customer service, filament manufacturers are helping to drive innovation in the 3D printing industry.

Isopropyl Alcohol

Isopropyl alcohol, commonly referred to as rubbing alcohol, is a colourless and flammable chemical compound with a distinctive odour. It is an effective solvent and cleaning agent for many surfaces and materials. Isopropyl alcohol is also used in the 3D printing industry to clean certain parts of the printer before and after use. This helps to ensure that the quality of prints is not compromised by any dirt or dust particles.

The effectiveness of isopropyl alcohol as a cleaning agent makes it an essential part of 3D printing maintenance. Additionally, its ability to evaporate quickly means that it does not leave behind any residue that could potentially cause problems with the printer’s operation. Isopropyl alcohol is an important tool for keeping 3D printers running smoothly and producing high-quality prints.

Glass Transition Temperature

Glass transition temperature (Tg) is an important physical property of a material that affects its performance in various applications, such as 3D printing. It is the temperature at which a material transitions from a glassy state to a rubbery or plastic state.

At this temperature, the molecular bonds become weak and the material starts to soften, allowing for more flexibility and easier manipulation. This property is especially important for 3D printing since materials with higher Tg will require higher temperatures when melting them before they can be extruded into their desired shape.

By understanding the Tg of different materials, it is possible to select the most suitable one for any given 3D printing application. Additionally, controlling the Tg of a particular material can help ensure consistent quality prints by avoiding unnecessary warping or cracking during the cooling stage.

Processes and Preparation

Processes and Preparation are essential parts of successful 3D printing. Preparing the model for 3D printing involves cleaning, repairing, slicing, orienting, scaling and positioning the model. After this step is completed, the 3D printer must be calibrated to ensure that it is ready and able to print the desired object.

Once these steps are done and all materials needed are available, the actual printing process can begin. It usually involves heating up a filament material such as plastic or metal to its glass transition temperature before it can be extruded through a nozzle onto a build plate in order to create the desired shape layer by layer. Proper preparation and processes are essential for high-quality prints that meet all of your specifications.

Print Bed Levelling Process

Print bed levelling is an important process that must be performed before 3D printing. It involves adjusting the printer’s build plate so it is level and at the same height for each corner. This ensures that the filament material will remain consistent in the extrusion process and that the print will have a uniform surface finish.

The process typically begins by turning off the power to the 3D printer and then removing any objects from the print bed. Next, using a feeler gauge or ruler, measure each corner of the print bed in order to detect any irregularities in height. If necessary, use adjustable screws on the bottom of the printer to level out any differences.

Once this is complete, turn on your 3D printer again and check its functionality with a test print. Following these steps can help ensure quality prints every time!

Nozzle Temperature Setting

Nozzle temperature is one of the most important settings to get right when 3D printing. It affects the amount of material that can be extruded, as well as the part’s surface finish and strength. Different filament materials require different temperatures in order to be properly extruded, so it’s important to check the recommended range for your specific filament type before beginning a print.

Generally, the nozzle temperature should be set somewhere between 180-220°C for PLA, and 210-250°C for ABS. To adjust the temperature on your 3D printer, simply use the appropriate controls on your machine or through its software interface. By taking time to properly set up your printer’s nozzle temperature, you can ensure that your prints come out looking perfect every time!