How much does 3d printing cost per hour?

Have you ever wondered how much it costs to use a 3D printer for an hour? As the popularity of 3D printing continues to grow, so does the demand for information on its cost implications. Whether you’re a hobbyist or a business owner, understanding the costs associated with 3D printing is crucial to prevent overspending.

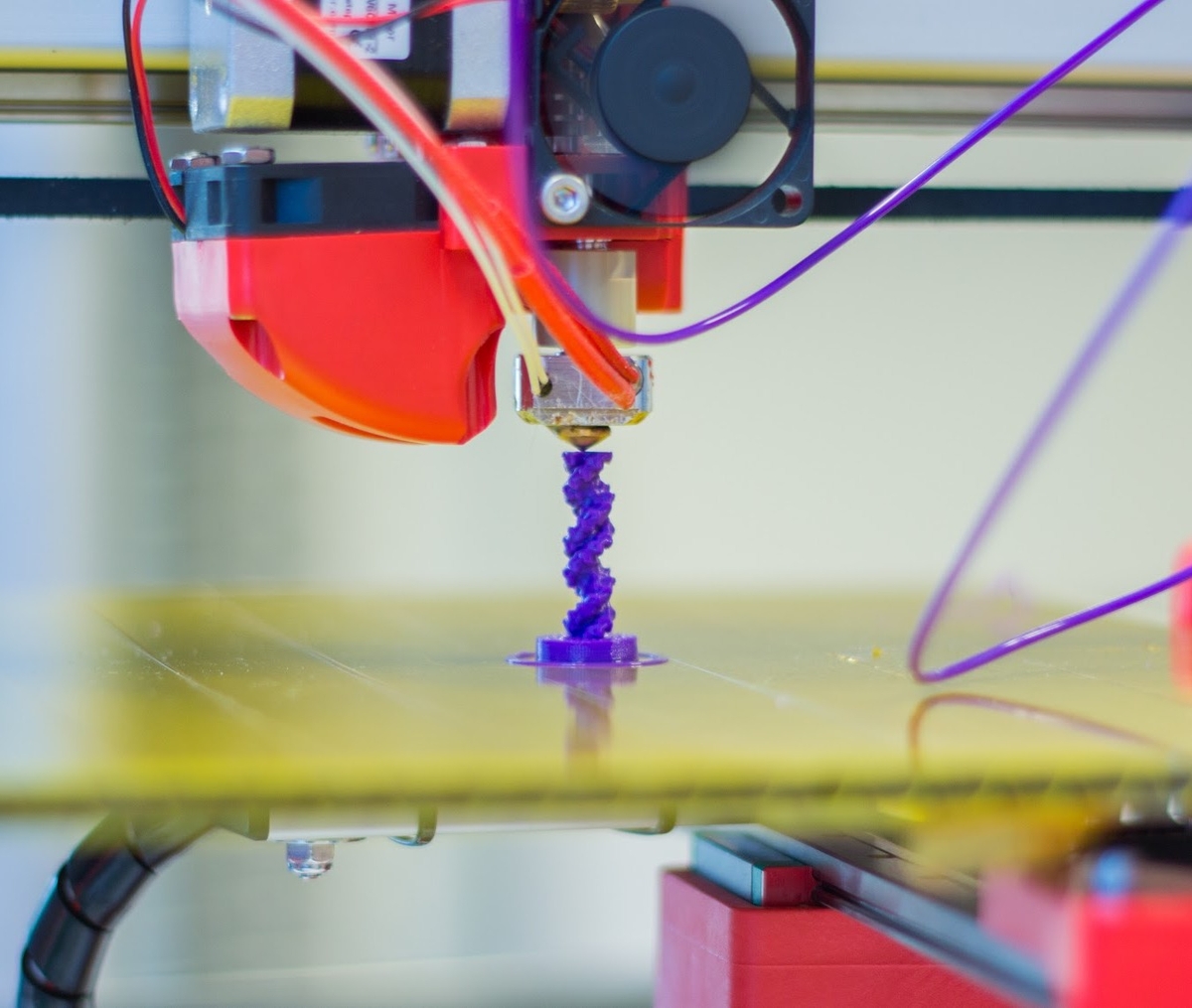

3D printing has revolutionized the manufacturing industry, allowing for the creation of complex designs that were previously impossible. However, with the technology being relatively new, there is still a lot of uncertainty surrounding its costs. Many factors come into play when calculating the cost of 3D printing, including the type of printer, materials used, and the printing speed.

If you’re considering investing in a 3D printer or using one for a project, it’s essential to understand how much it costs per hour. In this article, we’ll break down the factors that contribute to the cost of 3D printing per hour, enabling you to make an informed decision when it comes to your printing needs.

How much does 3D printing cost per hour?

Three-dimensional printing or 3D printing has opened opportunities to practitioners in the manufacturing industry who have access to this technology. It is a revolutionary approach to manufacturing, now allowing engineers and designers to create parts or functional prototypes from a whole in a much quicker, cost effective and efficient way. With 3D printing, individuals no longer need to start with a whole and then go through the process of deductive thinking while machining away material until they reach their desired part or prototype.

Thanks to the advancements in 3D printing technology, people have the ability to produce complex designs that would usually be impossible with traditional subtractive methods such as CNC machining. Not only does three-dimensional printing provide overall shorter lead times for production than traditional methods but also offers greater control for manufacturers over variables like surface finish, errors and defects. Furthermore, with 3D printing, it’s possible to customize a model or design quickly as changes can be easily made and implemented. You may be asking how much does 3D printing cost per hour? The answer is always different depending on the vendor and what type of materials are being used in production. Additionally, some aspects of your project may increase cost such as complexity of the design or how long it takes for parts to print. On average, however, the cost of 3D printing per hour is usually around $35-50 for a small machine and can be up to $200 for larger machines.

In conclusion, 3D printing is an increasingly popular technology that has revolutionized the manufacturing industry. The cost of 3D printing per hour varies depending on several factors, including the type of printer, materials used, and printing speed. It is important to understand this variable cost when planning your 3D printing projects to ensure that you don’t go over budget.

Is it expensive to 3D print?

3D printing is becoming increasingly popular and with that increased popularity comes the question of how expensive it can be. There is no easy answer since the cost of 3D printing depends on various factors. The most significant are the material types being used, the complexity of a design, labor required for assembly and other similar factors. The initial purchase of the 3D printer also plays a major part but doesn’t represent the entire expenditure.

The type of printer can also have an effect on costs. For example, resin-based printers are typically pricier up front than FDM 3D printers but they can provide much better value to professional users in the long run due to their heightened performance capabilities such as better part quality, smoother finishes and finer detail, greater throughput, and build chamber utilization (especially mSLA printers). As you can see, depending on what technology is used 3D printing can actually be very cost-effective if done right.

What impacts 3D printer pricing and costs?

One of the main factors that plays a role in 3D printer pricing and costs is the quality of parts and materials used. Higher-end models of 3D printers will typically use higher quality internal components such as motors, electronic components, or metals like copper or steel. This will naturally increase the cost. Additionally, different brands may have different prices depending on their reputation and customer service/support offered with their products.

Another factor that affects 3D printer pricing and costs is the type of filaments used for printing. Generally speaking, more expensive materials mean more costly 3D printing jobs; for example, certain types of plastics can be more expensive than other types due to manufacturing complexity, availability and durability. Different types of filaments not only require different amounts of plastic powder but each kind has its own set of pros and cons related to the level of detail achievable during a print job. Depending on what applications you are using your 3D printer for, these variables should be carefully considered when deciding on an appropriate model and featureset.

Materials

Materials are a fundamental aspect of 3D printing, as the right material is required in order to achieve the desired result. Nexa3D offers a diverse range of materials for their photopolymer NXE 400, including thermoplastics and metals. Thermoplastics are highly adaptable and lightweight, making them suitable for a wide range of applications. Amongst some of the most commonly used types of thermoplastics in 3D printing are PC (polycarbonate), ABS (acrylonitrile butadiene styrene) and PLA (polylactic acid). As well as resin and filament materials, users can also choose from various metal materials such as stainless steel, titanium, brass, aluminum and copper alloys. Metal materials offer unparalleled strength and durability; however it often comes with a higher price tag than other options available. Therefore users must consider their needs carefully before opting to use metal materials in their project.

Size

Size is an increasingly important factor in modern printing, as the size of a printed object can affect both the cost and the time spent creating it. On one hand, larger-sized objects require additional materials, leading to higher costs. The amount of material used in a print job increases exponentially with increasing size, so larger objects end up much more expensive than smaller ones. Additionally, large-sized prints take a longer time to complete due to the prolonged printing process; if speed is of a concern, then consider using smaller objects instead.

The printer that is used to create the printed object also needs to be taken into account when considering size. For example, some 3D printers can easily accommodate small parts and objects but may not have enough space or power to print larger items. Also, large prints often require specialty printers with features such as specialized cartridges and heated beds for better precision and accuracy when printing big items. Generally speaking, purchasing a bigger printer comes with a bigger price tag so budget should also be considered carefully before investing in these more expensive machines.

Complexity

Complex designs require more complex processes in order to produce them. This means that they tend to be more expensive than simpler designs, due to the increased amount of resources and effort necessary for their production. When it comes to 3D printing, complexity is typically measured in terms of infill density, which refers to the number of extra layers within a 3D printed object. A higher infill rate generally equals a higher cost due to the additional materials needed for support structures and longer print times. Moreover, it can also increase printing costs if there is a need for multiple prints with various settings and material types; such as if different colors or plastic types are called for in order to complete the desired design.

In terms of aesthetics alone, complexity can deliver outstanding results with an eye-catching level of detail when done correctly. However, this often makes them far more intricate than simpler designs which can lead to more time consuming efforts and higher costs in the long run. Furthermore, any error during production would mean wasted time and resources which could undermine progress even further. As such, there are a few things to consider before opting for a complex design over a simpler one specifically when it comes to 3D printing. With all these factors considered, complex designs

Software

When it comes to 3D printing, the choice of software can make a huge difference in the quality and precision of your prints. 3D printer manufacturers often offer proprietary software to accompany their hardware, though third-party open-source programs such as Cura and Slic3r are also available. Both software types have their own advantages and disadvantages.

For those willing to invest more in their 3D printing experience, proprietary software typically offers a wider range of features and capabilities than open-source options. While the initial cost for these programs may be greater, they often provide added convenience by streamlining setup processes and automating tasks such as filament changing or parameter adjustments. On top of that, proprietary software is usually linked with dedicated support from the manufacturer so users get access to timely help should they encounter technical issues.

Electricity

Electricity plays an important role in the functioning of a 3D printer. The usage of electricity can vary based on the type of material and print size that it is required to print. On average, consumer-grade 3D printers require about 0.5kWh for operation, but this number greatly increases for industrial grade 3D printers that require higher voltage outlets and can consume significant amounts of electricity in order to print complex pieces.

In order to minimize electricity consumption, advanced 3D printers are now equipped with energy efficient technologies. These technologies enable the machine to use the least amount of electricity while maintaining excellent quality prints. Additionally, more and more 3D printers are offering eco-friendly modes which further reduce power consumption whenever possible during the printing process. As such, these advanced technologies make it possible for users to create quality prints without compromising on energy efficiency or costing more money due to high electricity usage.

Post-processing

Post-processing is an essential part of the industrial manufacturing process that can add a considerable amount of time, cost and labor to the production cycle. In order to ensure quality end products and cost-effective production, post-processing typically involves additional materials (such as paint, adhesives or coatings), accessories, time and even skilled technicians. This lengthy associated process has been a burden for many manufacturers who are looking for ways to reduce costs and streamline post-processing operations.

Luckily, there are new technologies on the market aimed at reducing the time, money and manpower needed for industrial post-processing. For instance, Nexa 3Ds xWash and xCure systems integrate necessary post-processing features directly into the 3D printing process– eliminating the need for manual labor or additional machinery or materials. This allows operators to drastically reduce their reliance on traditional post-processing techniques like manual sanding, ultimate resulting in cost savings across both labor and material costs.