How to 3d print without a 3d printer?

Have you ever wished you could bring your digital design to life, but don’t have access to a 3D printer? The good news is that you can still make it happen.

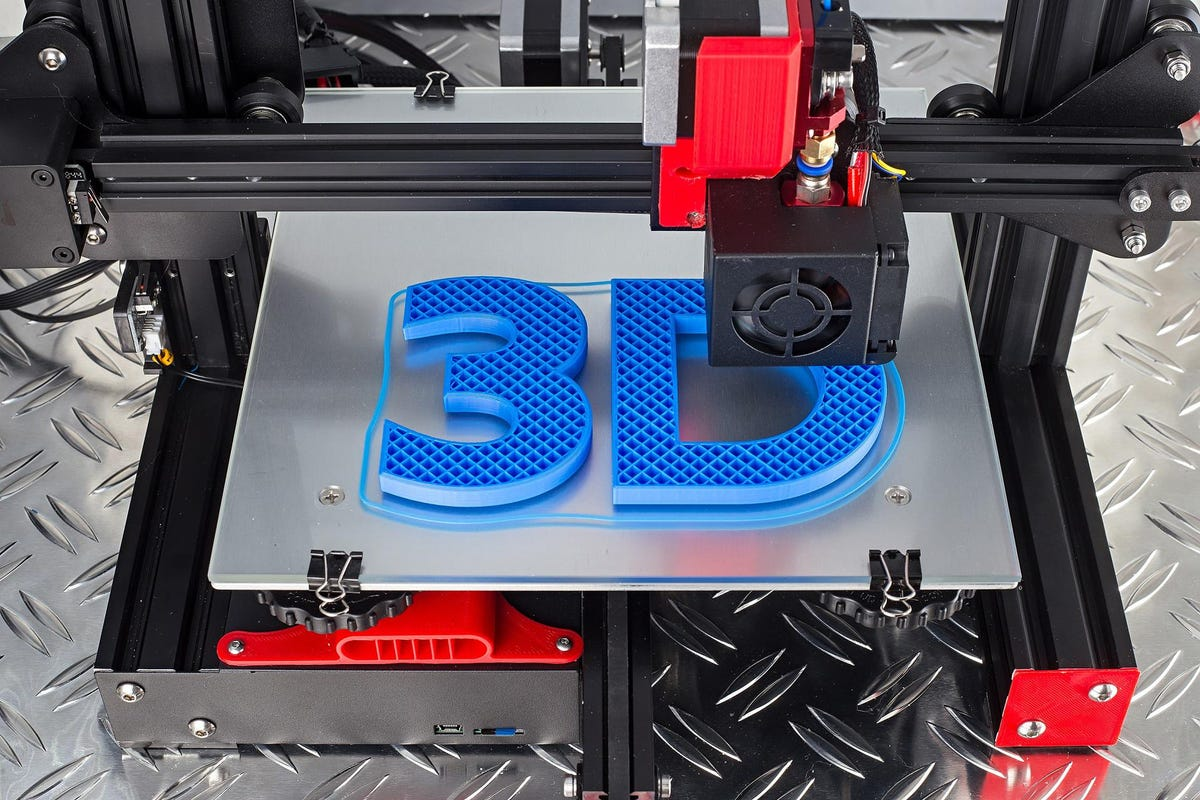

3D printing has revolutionized the manufacturing industry, allowing us to create complex objects through the layer-by-layer deposition of materials. But not everyone has the budget or resources to own a 3D printer. Luckily, there are alternative methods to achieve similar results.

In this article, we will explore various techniques and tools you can use to 3D print without a 3D printer. Whether you’re a DIY enthusiast or a professional designer, you’ll discover how to turn your ideas into physical objects, using readily available materials and equipment. So let’s dive into the world of 3D printing, without actually owning a printer.

Why 3D Print Without a Printer?

3D printing without a printer is an attractive option for anyone who wants to create custom parts, prototypes or finished products. It eliminates the need for costly and complex 3D printers and makes it easy to get started with 3D printing. With services such as Shapeways or Sculpteo, customers can upload their designs and have them printed using the latest technology without any of the hassle associated with setting up a 3D printer.

Furthermore, these services offer access to a range of materials and finishes that would not be available through traditional 3D printing methods. This allows users to explore new creative possibilities when designing their products. By utilizing these services, individuals can save time and money while still achieving high-quality results.

Gather the Necessary Materials

When 3D printing without a printer, it’s important to make sure that you have the necessary materials and tools for the job. First and foremost, you’ll need a design or model in either STL or OBJ format. Without this, there will be no way to create a 3D printed part. Additionally, you’ll need access to a 3D printing service such as Shapeways or Sculpteo which allows you to upload your designs and order prints.

Finally, depending on what type of material you’re interested in using for your print, you may need additional supplies such as paint or sealants depending on the type of finish that you want. By gathering all of these materials ahead of time, it will make the process of 3D printing without a printer much easier and efficient.

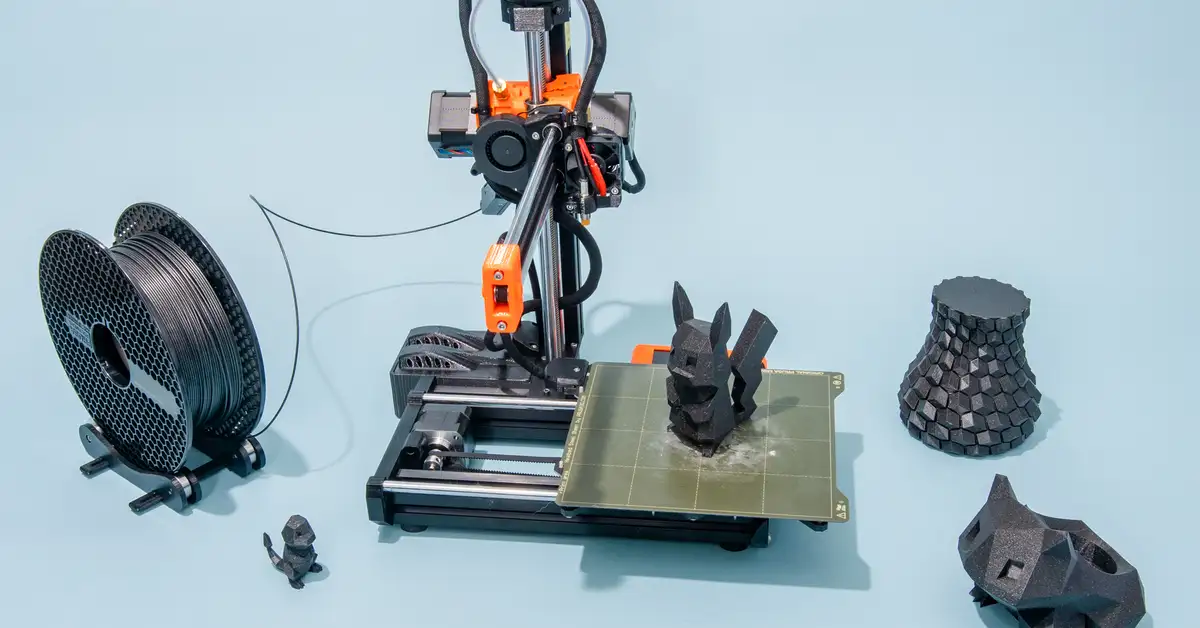

Filament

Filament is an essential part of 3D printing, and it is the material that is used to create the 3D print. There are a variety of types of filaments available, each with their own unique benefits and drawbacks. PLA is one of the most popular materials for 3D printing as it has low shrinkage and warping tendencies as well as a wide range of colors and finishes.

ABS plastic is another common filament choice due to its high strength and durability, but it can be difficult to work with due to its tendency to warp when heated. PETG filament is a great alternative for those looking for a strong, durable material that also has good temperature resistance. Finally, Nylon filament offers excellent flexibility while remaining extremely tough and durable. By selecting the right type of filament for your project, you can ensure that your 3D prints come out looking perfect every time!

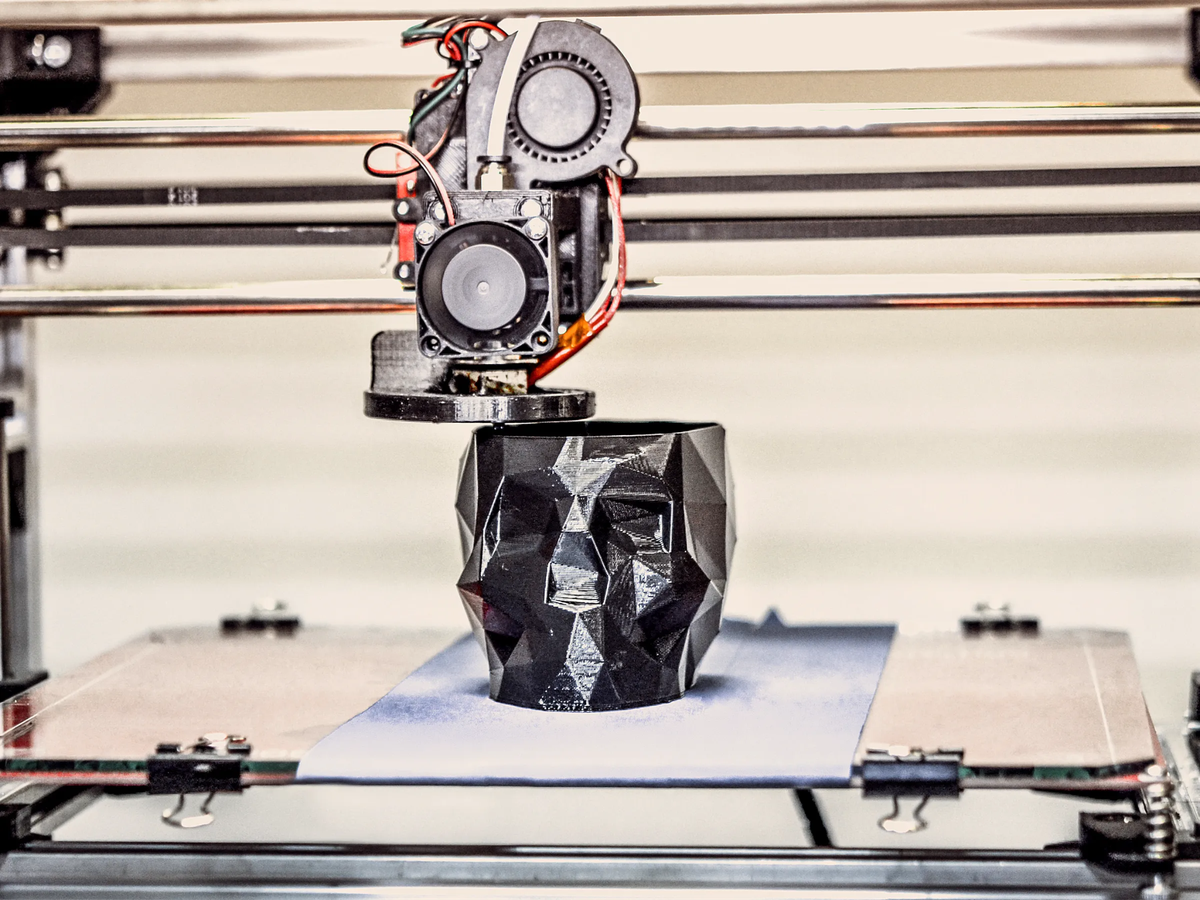

Build Platform

The build platform is the foundation of every 3D printer, and it is the surface on which the 3D object will be built. It is important to choose a platform that is large enough to accommodate the size of your project, as well as one that will provide stability during the printing process. The platform should also be level and flat, so that your prints come out looking even and smooth.

Additionally, you’ll want to select a material for your build platform that can withstand high temperatures and won’t warp when heated. Common materials used for build platforms are glass or aluminum plates; however, more specialized options such as ceramic or copper-coated surfaces are becoming increasingly popular due to their superior heat resistance properties. Whatever material you choose for your build platform, make sure it is level and stable before you begin printing!

Computer/Laptop

Whether you’re a student, professional, or casual user, having a computer or laptop is essential for day-to-day activities. When selecting the right computer for your needs, there are several factors to consider such as size, processing power, and storage capacity. Laptops are perfect for those on the go who want a lightweight option that is easy to transport; however, desktop models tend to be more powerful and offer more expandability.

No matter what type of device you choose, make sure it has enough RAM to handle your tasks and enough storage space for all your files. Finally, look at features like backlit keyboards and touchscreen capabilities if you need extra convenience and accessibility. With so many options available today, finding the right computer or laptop has never been easier!

USB Drive

USB drives are a great way to store and transport data. These small, pen-sized devices provide quick access to documents, photos, music, and other digital content. With plenty of storage options available, you can easily find the right capacity for your needs. USB drives also boast fast transfer speeds so you won’t have to wait around for files to copy over.

They are also incredibly durable and resistant to shocks and drops, making them ideal for travel. Furthermore, most USB drives don’t require any special software or drivers to work; simply plug it into your computer and start transferring data! With their compact size and convenience, USB drives are an essential tool for anyone who needs easy access to their digital content on the go.

Software for Slicing and Printing

Software for slicing and printing is an important part of 3D printing. Slicing software takes a 3D model and cuts it into thin layers that the printer can then print in sequence to form the final object. It also modifies the model to make sure that it is suitable for 3D printing, such as by thickening some areas or adding extra support structures. There are many slicing programs available, ranging from free open-source solutions to paid professional-grade software.

The right program will depend on your specific needs, so be sure to do some research before making a decision. In general, most users should be able to get by with a basic but reliable slicer; however, more experienced users may want to invest in more advanced features like multi-material support or auto-slicing capabilities. Regardless of which program you decide on, having the right software makes all the difference when it comes to successful 3D printing!

Prepare Your Object Model File for 3D Printing

Preparing your 3D model file for 3D printing is an important step in the process. The first thing to do is make sure you have a high-quality mesh with no errors or inconsistencies. If not, use a mesh repair program to fix any issues. Additionally, you may need to scale and orient your model so that it fits on the print bed and prints correctly.

Also, consider adding support structures if your object has any overhangs or parts that could be prone to warping or breaking during printing. Finally, export the model as an STL file, which is the standard format used for 3D printing. With these steps complete, you can confidently send your model off to be printed!

Find a 3D Model File to Print

Finding a 3D model file to print can be a daunting task. Fortunately, there are many sources for 3D models available online. Popular websites like Thingiverse, MyMiniFactory, and Yeggi offer thousands of free STL files that are ready to download and print. Alternatively, you could create your own model using a 3D modeling software such as Blender or Fusion 360.

This requires more skill and knowledge, but it also gives you the freedom to create an object with any design or shape that you desire. Additionally, some companies offer custom 3D printing services where they will take your design specifications and turn them into a physical object. With these options in mind, you should have no problem finding the perfect 3D model file for your next project!