Is 3d printing worth it?

3D printing has gained a lot of attention in recent years, but is it really worth the hype? With the industry growing rapidly, it’s important to consider the benefits and drawbacks of 3D printing before investing in the technology.

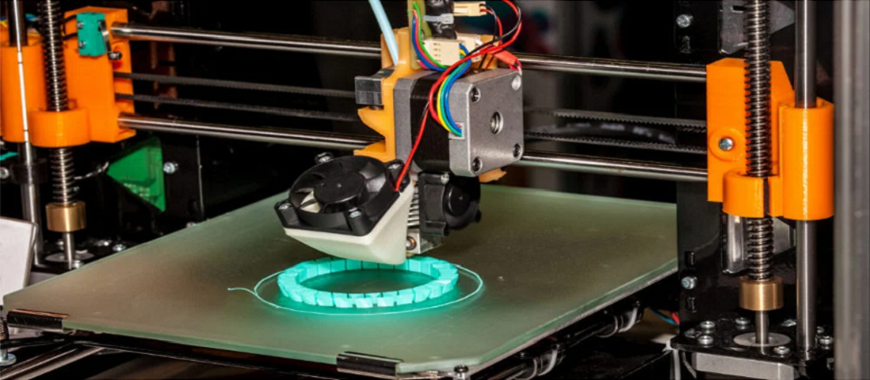

3D printing is a process of creating three-dimensional objects from a digital file. It has revolutionized various industries such as manufacturing, medicine, and architecture, but it also comes with its own set of challenges. The cost of 3D printers, materials, and maintenance can be high, which raises the question – is 3D printing worth it?

In this article, we will explore the pros and cons of 3D printing, and whether investing in the technology is a wise decision. We will weigh its benefits and drawbacks to help you make an informed decision, and assist you in determining whether 3D printing is valuable enough for your needs, budget and goals.

Benefits of 3D Printing

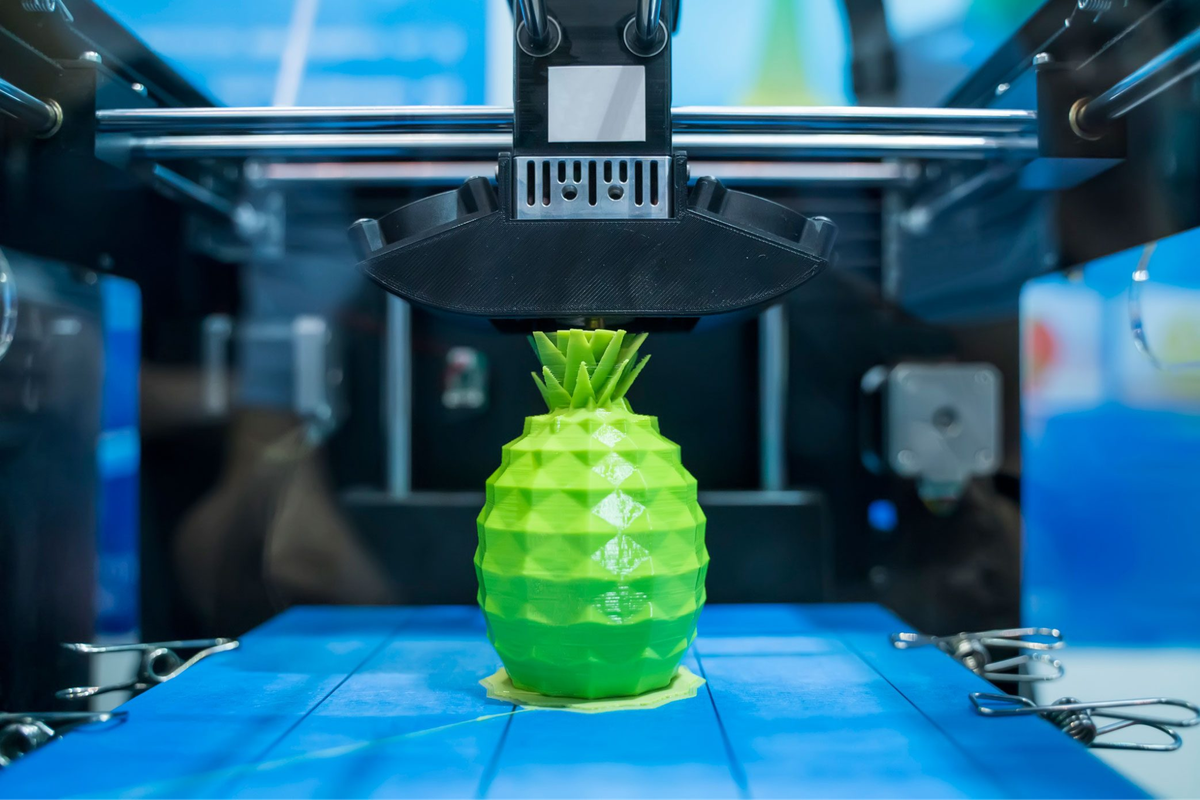

The benefits of 3D printing are numerous, making it a popular choice for prototyping, product design, custom manufacturing, medical research and more. 3D printing offers advantages such as fast turnaround times and cost savings when compared to traditional manufacturing methods. Additionally, 3D printing enables users to create complex shapes that would otherwise be too difficult or costly to manufacture using traditional methods.

Furthermore, 3D printing provides an opportunity for makers and DIY enthusiasts to bring their ideas to life without having any prior experience with engineering or design. With its versatility and affordability, 3D printing is becoming increasingly popular among businesses and individuals alike. Whether you’re looking for a cost effective way of bringing your ideas to life or need large quantities of parts quickly, 3D printing may be the right choice for you.

Cost Considerations

When it comes to 3D printing, cost considerations can be a major factor in deciding whether or not the technology is worth the investment. Depending on what you plan on printing and how often, costs can range from relatively inexpensive for smaller items to expensive for more complex designs. Additionally, 3D printer materials such as filament, resins and powders can add up over time if you’re using the technology frequently.

In terms of long-term savings, however, 3D printing may be worth considering if you need multiple copies of an object or are looking to save money on prototyping or production costs. Furthermore, many 3D printers have a low initial cost that may make them more attractive than traditional manufacturing methods. Ultimately, it’s important to weigh your options carefully before making any decisions as there are many factors that go into determining whether 3D printing is right for you.

Initial Cost

When it comes to 3D printing, the initial cost can be a major deciding factor in whether or not it is worth pursuing. Depending on the type of printer you get, costs can vary from relatively inexpensive for smaller items to expensive for more complex models. Additionally, there are a variety of materials you may need such as filament, resins and powders that can add up over time if you’re using the technology frequently.

However, many 3D printers have an initial cost that may be lower than traditional manufacturing methods. This makes them an attractive option if you’re looking to save money on prototyping or production costs without sacrificing quality. Ultimately, it’s important to carefully consider your options before investing in a 3D printer as there are many factors that go into determining whether it is the right choice for your needs.

Cost of 3D Printing Materials

The cost of materials for 3D printing is an important factor to consider when deciding if the technology is worth it. There are a variety of materials available, ranging from inexpensive filaments like PLA and ABS to more expensive resins and powders. The type of material you use will depend on the application and desired results, as each one offers different advantages. It’s important to research what materials are best suited for your needs and compare prices before making a purchase.

Additionally, some types of materials may require additional preparation or post-processing steps that could add to your overall costs. Ultimately, understanding the cost of materials as well as any associated labor costs can help you determine if 3D printing is worth it for your project.

Cost of Premium Printers for Detailed Models and Miniatures

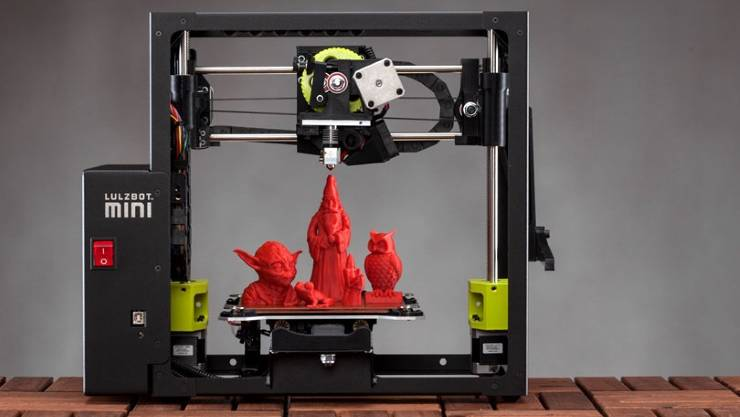

Premium 3D printers can produce highly detailed models and miniatures with amazing accuracy and precision. However, these machines come at a hefty price tag, making them out of reach for many hobbyists. Depending on the printer and features you need, these machines can cost anywhere from a few hundred to several thousand dollars.

Investing in a high-end 3D printer requires careful consideration of your budget and needs. Generally speaking, the more expensive printers offer better resolution and faster print speeds while allowing for more prints in less time. Before purchasing a premium 3D printer, make sure to compare different models and read user reviews to ensure that you get the best value for your money.

Additionally, consider if you will need any additional materials or tools that could add to the overall cost of your purchase. Ultimately, deciding whether or not investing in a premium 3D printer is worth it depends on individual projects and preferences.

Money in 3D Printing Businesses

Starting a 3D printing business can be an exciting and lucrative venture, but it is important to consider the financial side of the operation before making any major investments. Depending on the type of printing services you offer, you may need to purchase specialized equipment and materials that can add up quickly. Additionally, depending on the size and scope of your business, you may require staff or storage space for inventory.

Before taking any steps towards setting up a 3D printing business, be sure to research all costs associated with running such an operation and create a budget accordingly. Additionally, consider potential sources of funding such as loans or grants from local governments or organizations if needed. With careful planning and financial management, a 3D printing business can be an excellent source of income.

Worthy Investment? Initial Investment vs. Long Term Profitability

When it comes to 3D printing, the initial investment can be quite large. Many businesses are looking at thousands of dollars in equipment and materials before they even begin their operations. However, despite the large up-front cost, 3D printing can be a very worthy investment in the long run. Long term profitability depends on many factors such as demand for the services offered, pricing structure, and competition level in the area.

By researching potential markets and creating a sound business plan with realistic goals, 3D printing businesses can often see positive returns from their investments within just a few years. The key to success lies in carefully planning out all aspects of the business before investing any money. Researching potential markets is essential for understanding what services may be most profitable and what prices customers are willing to pay for them.

Additionally, by considering costs associated with staff or storage space upfront, businesses can ensure that their investments are well spent and will help them reach their long-term goals. With careful planning and financial management, 3D printing can be an excellent source of income over time.

Types of Printers and Print Quality

3D printing has become increasingly popular in recent years, and many people are wondering if it is worth the money. The answer depends on a few factors, including what type of printer you buy and the quality of prints that you desire. There are several types of 3D printers available on the market today. Each type offers different benefits and drawbacks that should be considered before purchasing. The most common types are Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS) and Digital Light Processing (DLP).

FDM is the most affordable option, but it is also limited in terms of print quality as well as material options. SLA offers higher resolution prints with a wider range of materials, but it tends to be more expensive. SLS and DLP offer even higher resolution prints with a variety of materials, but they tend to be very expensive. The quality of prints from any 3D printer ultimately depends on its build volume, layer height, nozzle size, printing speed and other features.

Generally speaking, larger build volumes allow for larger objects to be printed while smaller layer heights produce smoother surfaces. Smaller nozzles allow for finer details to be printed while faster speeds reduce overall print time. All these features come at a cost though; higher-end 3D printers tend to have better specs than lower-end models which makes them more expensive.

In conclusion, whether or not 3D printing is worth it comes down to personal preference and budget constraints. If you’re looking for high-quality prints with a wide range of materials then an SLA or DLP printer may be worth the investment; however if you