Non-planar 3d printing all you need to know

Have you ever wondered how 3D printing works? Most of us are familiar with the process of printing a flat design onto paper, but how does it work when it comes to creating three-dimensional objects? And what about non-planar 3D printing?

3D printing has revolutionized the way we create objects, from simple toys to complex prosthetics. However, traditional 3D printing has limitations when it comes to creating curved or irregular shapes. This is where non-planar 3D printing comes in.

Non-planar 3D printing is a technique that allows for the creation of complex, curved shapes that traditional 3D printing cannot achieve. In this article, we will explore what non-planar 3D printing is, how it works, and its potential applications. Whether you are a designer, engineer, or simply curious about the latest technology, this article will give you all the information you need to know about non-planar 3D printing.

Non-Planar 3D Printing: All You Need to Know

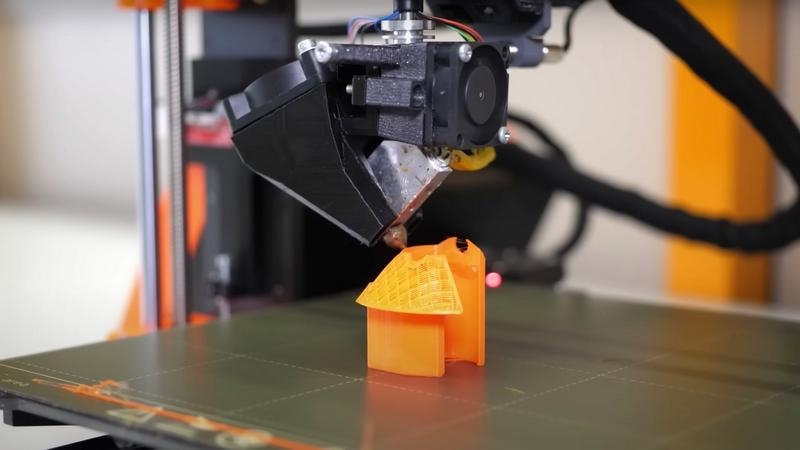

Non-planar 3D printing is a method of printing three-dimensional objects that features curves, contours, and other irregular shapes. It works by adding layers of material to create an object from the bottom up. Instead of using a flat surface as its base, non-planar 3D printing uses a curved one. This allows for the creation of complex shapes that traditional 3D printing cannot achieve.

The process of non-planar 3D printing is similar to traditional 3D printing in that it begins with a computer-aided design (CAD) program to create the object’s design. The model is then sliced into thin layers and sent to the 3D printer. The printer deposits material onto the curved surface according to the programmed instructions. Each layer is then bonded to the previous layer until the object is completed.

Non-planar 3D printing has a wide range of potential applications. It can be used to create custom prosthetics, vehicle components, medical tools and more. This technology can also be used for rapid prototyping and low-volume production, allowing designers and engineers to quickly experiment with new ideas without having to invest in expensive equipment .

Non-planar 3D printing is an exciting and innovative technology that has the potential to revolutionize the way we create objects. Whether you are a designer, engineer, or simply curious about the latest technology, understanding non-planar 3D printing will be invaluable in navigating this ever-changing landscape.

Smooth and Curvy

Non-planar 3D printing is an innovative technology that offers a wide range of benefits over traditional 3D printing. Its ability to create smooth, curved surfaces makes it ideal for creating objects with complex shapes and intricate details. This technology also allows for more accurate representations of real-world objects, as well as improved aesthetics for various applications.

In the manufacturing world, non-planar 3D printing can be used to create custom parts and components with greater precision and accuracy than ever before. This technology can also be used to quickly produce prototypes for testing, allowing designers and engineers to experiment with new ideas without having to invest in expensive equipment.

Non-planar 3D printing is an exciting and innovative technology with a wide range of potential applications. Whether you are a designer, engineer, or simply curious about the latest technology, understanding non-planar 3D printing will be invaluable in navigating this ever-changing landscape.

Suitable Types of Models

Non-planar 3D printing is a great tool for creating complex, curved shapes. This makes it ideal for medical tools, prosthetics, vehicle components, and more. The technology can also be used for rapid prototyping and low-volume production of parts and products. Additionally, non-planar 3D printing can be used to create accurate representations of real-world objects with intricate details.

Non-planar 3D printing is a versatile technology that can be used for a variety of applications. It is an ideal choice for creating medical tools with intricate details, as well as custom parts and components for vehicles. This technology can also be used to quickly produce prototypes, allowing designers and engineers to experiment with new ideas without the need for expensive equipment. Furthermore, non-planar 3D printing can be used to create accurate representations of real-world objects with intricate details.

Compatible Software

Non-planar 3D printing is driven by computer-aided design (CAD) programs. These software tools allow users to create accurate models of objects with complex shapes and intricate details.

Popular CAD programs for non-planar 3D printing include Fusion 360, Autodesk Inventor, Solidworks, and SolidEdge. Additionally, most 3D printers are compatible with a variety of 3D printing software tools, such as Simplify3D, MakerBot Print, and Cura.

How It Works

Non-planar 3D printing is a relatively new technology, but it has quickly become an invaluable tool for designers and engineers. This technology works by combining CAD models with specialized extrusion techniques to create objects with smooth and curved surfaces.

The process begins with a CAD model of the object being created. This model is then sliced into thin layers which are printed one at a time using a specialized extrusion head that follows the contours of the model. As each layer is printed, it is fused to the previous one, creating a three-dimensional object with smooth curved surfaces.

Pros & Cons

The biggest advantage of non-planar 3D printing is its ability to create complex, curved shapes with greater accuracy and precision than traditional 3D printing methods. This technology also allows for rapid prototyping and low-volume production of parts and products.

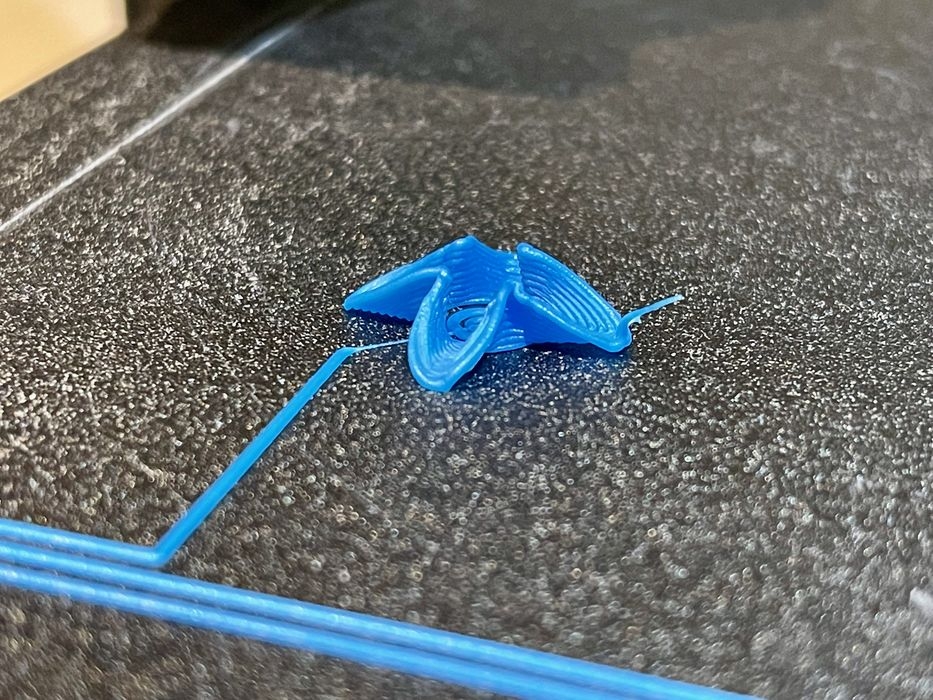

However, non-planar 3D printing can be costly due to the specialized equipment required. Additionally, this type of printing may require significant post-processing to achieve a finished product.

One of the main advantages of non-planar 3D printing is its ability to produce objects with intricate details. This technology can be used to create finely detailed medical tools, prosthetics, vehicle components, and more. It also offers designers and engineers the opportunity to quickly produce prototypes for testing new ideas without having to invest in expensive equipment. Furthermore, non-planar 3D printing can be used to accurately represent real-world objects with complex shapes and intricate details.

How to Start

If you are interested in getting started with non-planar 3D printing, the first step is to find a compatible 3D printer. Additionally, you will need to select the right type of filament for your project. There are several types of filaments available, including PLA, ABS, and nylon. You’ll also need to choose a compatible CAD program such as Fusion 360 or Autodesk Inventor.

Once you have all the necessary materials, you can begin creating your 3D models using the CAD program of your choice. After designing your model, it is time to export the file to your 3D printer and begin printing.

What is Next

Non-planar 3D printing is an exciting new technology that offers designers and engineers the opportunity to quickly produce complex shapes with intricate details. This technology is still relatively new, but its potential applications are vast. As the technology continues to evolve, it will no doubt open up a world of possibilities for product design and development.

The next step for non-planar 3D printing is to refine the technology for industrial applications. As the technology continues to evolve, it will be important to make sure that the process of 3D printing can handle high-volume production and large-scale projects. Additionally, it will be important to ensure that this technology is cost-effective and efficient. To achieve these goals, engineers and designers will need to continue to develop new techniques and materials for non-planar 3D printing.