3d printing without layer lines

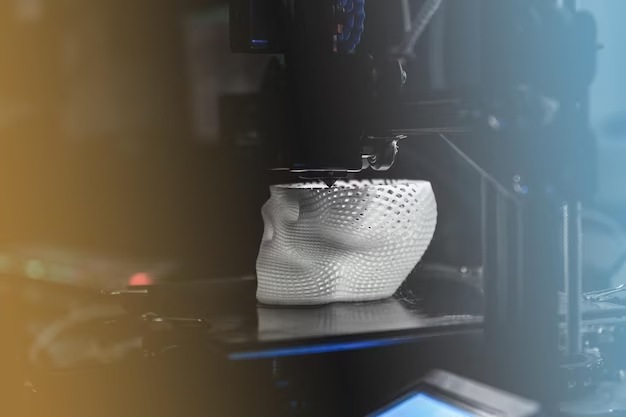

Have you ever looked at a 3D printed object and wondered why it has visible layer lines? No matter how precise the printer is, these lines always seem to be there. But what if there was a way to 3D print without any visible lines? Would it not only make the finished product look better, but also improve its strength and durability?

Layer lines are an inevitable and annoying aspect of 3D printing that have been a longstanding challenge for the industry. These lines are created as the printer moves horizontally to create each layer, leaving behind visible ridges and lines on the object. However, new technology is emerging that could eliminate these lines altogether.

3D printing has revolutionized the manufacturing and prototyping industry, but the battle against layer lines has been ongoing. The good news is that there are now alternatives to traditional 3D printing that can produce objects without any visible lines.

This breakthrough technology is changing the face of 3D printing and opening up new possibilities for designers, engineers, and manufacturers alike. In this article, we’ll explore the technology behind 3D printing without layer lines and how it can benefit a variety of industries.

What are Layer Lines?

Layer lines are an unavoidable aspect of 3D printing. They are the visible horizontal ridges seen on the surface of 3D printed objects and can be caused by a number of factors, including extrusion temperature, material properties, and layer height.

Layer lines can range from barely noticeable to very pronounced depending on the part geometry, printing parameters and post-processing techniques used. To reduce layer lines, 3D printers can print with a finer nozzle size or slower print speed in order to produce higher resolution prints with fewer visible ridges.

Why Avoid Layer Lines?

Layer lines are not only visually distracting, but they can also affect the structural integrity of a 3D printed part. Excessive layer lines can weaken parts by compromising their strength and making them more susceptible to breakage or warping.

Layer lines also create rough surfaces which can be difficult to paint or finish, leading to an overall lower quality product. By avoiding layer lines, you can produce higher quality prints that look better and last longer. Additionally, reducing layer lines allows for faster printing speeds since there is less time required for each layer to cool before the next layer is added on top.

3D Printing Materials

3D printing materials come in a variety of forms and have been developed to meet the demands of different applications. Depending on the intended use, different types of materials can be used to ensure a successful print. For example, rigid plastics are commonly used for items that need to hold their shape, while more flexible materials such as rubber or ABS can be used for parts that need to bend or move without breaking.

There are also specialized materials with unique properties such as wood-like filaments and photopolymers resins for UV curing applications. With the right material selection, it’s possible to produce high quality 3D prints with minimal layer lines and improved surface finish. Along with selecting the correct material, proper settings must also be adjusted in order for the printer to successfully lay down the material in an even manner. This allows for faster printing speeds, better accuracy and less waste – resulting in higher quality prints at lower costs.

Types of Filament

Filament is the most commonly used material for 3D printing and comes in a variety of types depending on the application. PLA (Polylactic Acid) is one of the most popular filament types due to its low cost, ease of use, and wide range of colors. ABS (Acrylonitrile Butadiene Styrene) is another commonly used type that offers greater strength and durability than PLA.

It can also be post-processed with acetone for a glossy finish. Nylon is a strong yet flexible material that produces parts with excellent impact resistance and can be printed with high precision. HIPS (High Impact Polystyrene) is often used as a support structure material due to its ability to dissolve in limonene, while PETG (Polyethylene Terephthalate Glycol) offers greater flexibility compared to PLA without sacrificing strength or durability.

Lastly, metal filaments such as bronze or copper are becoming increasingly popular due to their unique aesthetic properties and strong mechanical properties.

Choosing the Right Filament for Your Printer

Choosing the right filament for your 3D printer is essential for achieving the best possible results. Different types of filament offer different characteristics such as strength, flexibility, and heat resistance. PLA (Polylactic Acid) is one of the most popular filaments and is known for its low cost, ease of use, and wide range of colors.

ABS (Acrylonitrile Butadiene Styrene) offers greater strength and durability than PLA but requires higher temperatures to print properly. Nylon is a strong yet flexible material that produces parts with excellent impact resistance while HIPS (High Impact Polystyrene) can be used as a support structure material due to its ability to dissolve in limonene. PETG (Polyethylene Terephthalate Glycol) offers greater flexibility compared to PLA without sacrificing strength or durability.

Lastly, metal filaments such as bronze or copper are becoming increasingly popular due to their unique aesthetic properties and strong mechanical properties. No matter what type of filament you choose, it’s important to make sure it is compatible with your 3D printer in order to get the most out of it.

Temperatures and Cooling Strategy

Temperature and cooling strategies play a crucial role in 3D printing. If the temperature of the print bed or extruder is too low, the material won’t be malleable enough to form layers properly. On the other hand, if it’s too high, plastic materials like PLA can deform and warp.

To address this issue, many 3D printers are equipped with cooling fans that direct air onto the print bed and/or extruder to help maintain optimal temperatures. It’s also important to consider ambient temperature when printing; if a room is too hot or humid, plastic materials will tend to warp more easily than usual. To achieve best results, make sure your printer is set up in an environment with a consistent temperature around 70°F (21°C).

Additionally, use a 3D printer enclosure for better temperature control and reduced warping. By taking these steps you can ensure that your prints come out looking great without any layer lines.

The Role of Layer Height

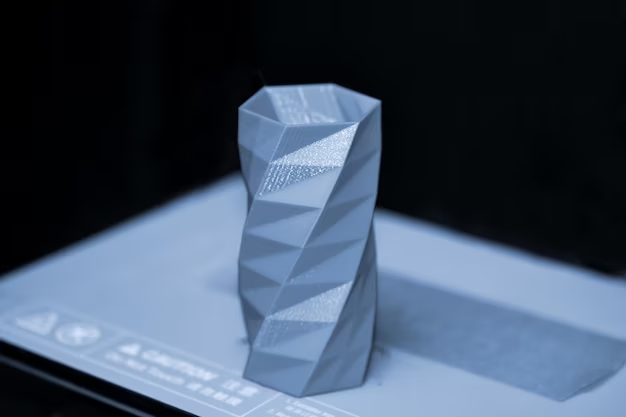

Layer height is an important factor to consider when 3D printing. It refers to the thickness of each layer, and it directly affects the quality and resolution of the final print. Generally speaking, lower layer heights result in smoother surfaces and finer details, while higher layer heights can lead to rougher textures.

The ideal layer height will vary depending on the specific application, but as a general rule of thumb it’s usually best to use the lowest possible layer height that still produces acceptable results. When selecting a layer height for a given project, it’s important to consider the size of your printer’s nozzle as well as the speed at which you’ll be printing. Slower speeds require slower layer heights in order to avoid clogging or other problems with too much material being deposited in one spot.

Additionally, some materials may require different settings than others; for example PLA is typically printed at 0.1mm or 0.2mm while ABS is usually printed at 0.25mm or higher. By taking all these factors into consideration you can ensure that your prints come out looking great without any issues caused by improper layer heights.

Thin Layers, Thin Lines

In 3D printing, thin layers and thin lines are essential for achieving a high-quality print. Thin layers provide the resolution needed to accurately reproduce even the most intricate details of an object. Thin lines are also important since they allow for smoother surface finishes and better control over the flow of material during printing.

Thin layers and thin lines can be achieved by using a low layer height setting on your 3D printer. Generally speaking, the lower the layer height is set, the thinner the layer and line will be. Additionally, some materials may require different settings than others; for example PLA is typically printed at 0.1mm or 0.2mm while ABS is usually printed at 0.25mm or higher.

By carefully selecting a layer height appropriate for your particular project and material type, you can ensure that you get smooth surface finishes with crisp detail without compromising on speed or accuracy.