Does room temperature affect 3d printing?

Have you ever wondered how the temperature of your printing environment affects your 3D printing results? Can a slight change in room temperature compromise your printed objects’ quality?

3D printing technology has revolutionized the world of manufacturing and product design in astonishing ways. However, a common doubt among 3D printing enthusiasts is how the temperature of their surroundings could impact the final product’s look and feel.

If you’re into 3D printing or planning to try it, understanding how environmental factors affect the quality of your models is essential. This article will discuss the possible impact of room temperature on 3D printing, what factors it affects, and how you can optimize your printing environment for a seamless printing experience.

Definition of 3D Printing

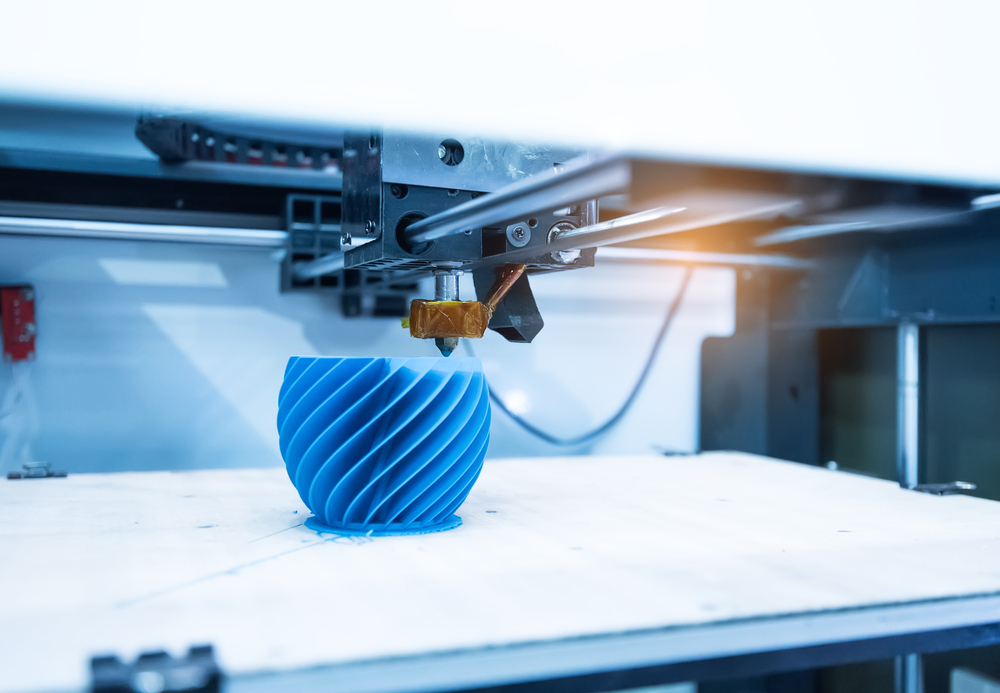

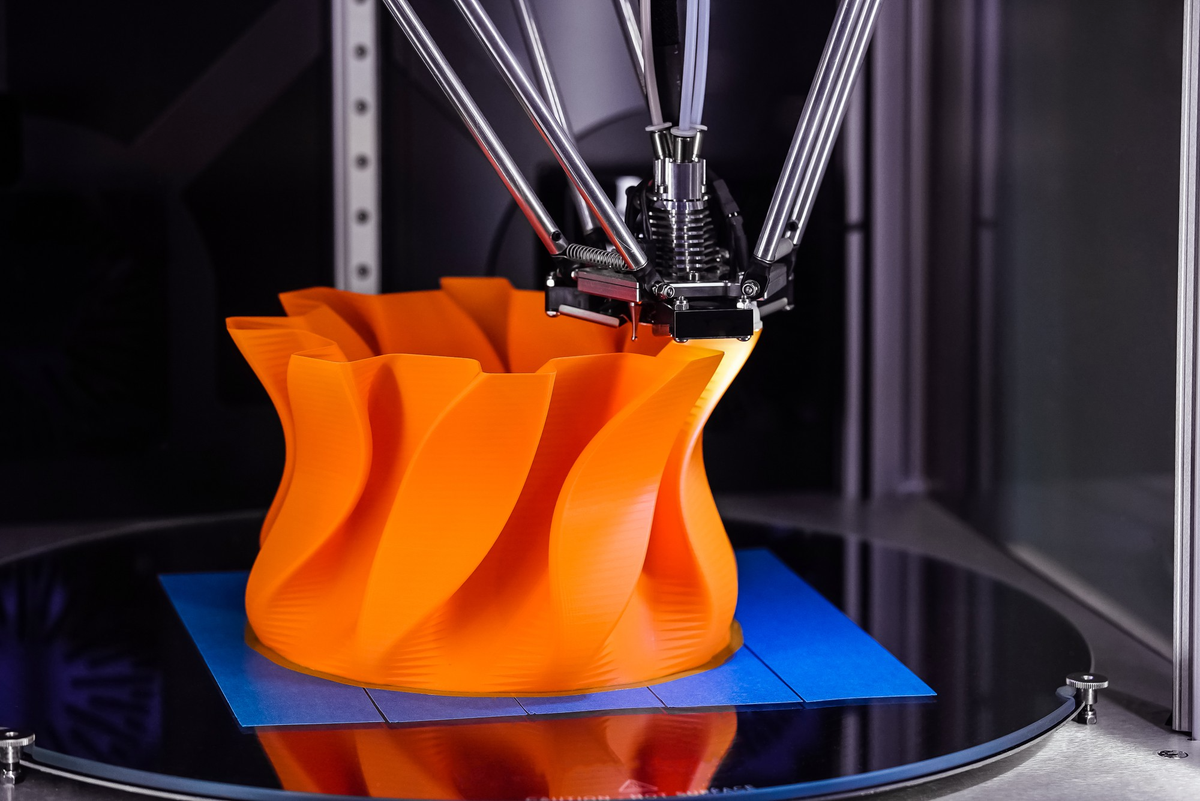

3D printing is an additive manufacturing process in which a physical object is created by depositing materials layer by layer. It is also known as additive fabrication or rapid prototyping, and can be used to produce anything from jewelry to airplanes. 3D printing works by using digital designs that are converted into three-dimensional objects using specialized software. The object is then printed in layers, starting with the bottom-most layer and gradually building up until the entire object has been completed.

Depending on the material being used, 3D printing can create highly detailed objects with intricate details. In addition to its accuracy and precision, 3D printing offers advantages such as faster production times and lower costs compared to traditional manufacturing methods. Ultimately, the technology has revolutionized many industries such as automotive, aerospace, consumer goods and healthcare.

Overview of Room Temperature

Room temperature is an important factor when it comes to 3D printing. Room temperature affects the speed and accuracy of the 3D printing process, as well as the overall quality of the parts produced. Generally speaking, most materials are best printed at temperatures between 18-30°C (64-86°F). Lower temperatures can slow down the extrusion rate, while higher temperatures can lead to warping or other defects in the final part.

Temperature also affects not just the material itself but also other components of the printer such as motors, fans and electronics. Keeping these items within a certain range helps ensure optimal performance and quality prints. Ultimately, having a controlled room temperature is key for successful 3D printing projects.

Purpose of the Article

The purpose of this article is to explain how room temperature affects 3D printing. Room temperature can have a significant impact on the speed, accuracy and overall quality of the 3D printing process. This article will provide an overview of what optimal temperatures are for various materials and components, as well as how to maintain those temperatures in order to achieve successful prints.

It will also provide information on what to do if certain parts become too hot or too cold during the printing process. By understanding how room temperature affects 3D printing, users can ensure that their prints come out with the best possible quality every time.

Room Temperature Basics

Maintaining the right room temperature is essential for successful 3D printing. Generally speaking, the optimal temperature for a 3D printer is between 20°C and 30°C (68-86°F). Anything outside of that range can cause problems such as warping or deformation. It’s also important to consider the material being used, as some materials require higher temperatures than others in order to achieve successful prints.

For instance, PLA plastic should be printed at temperatures between 190-220°C (374-428°F) while ABS plastic needs to be printed at temperatures between 220-250°C (428-482°F). Additionally, overheating certain components like the nozzle or extruder can lead to a variety of issues such as clogs, irregular layers and inconsistent extrusion. To prevent this from happening, it’s important to keep these parts cool by using a fan or other cooling device.

Furthermore, extreme cold can cause filament to become brittle or break off during the printing process. Therefore, it’s important to make sure that your workspace is not too cold either. By understanding how room temperature affects 3D printing and making sure to keep it within optimal ranges, users can ensure that their prints come out with the best possible quality every time.

Normal Range of Ambient Temperature

The ideal range of ambient temperature for 3D printing is between 20 and 30°C (68-86°F). Anything outside of this range can cause quality issues such as warping or deformation. It’s important to consider the material being used, as some materials require higher temperatures than others in order to achieve successful prints.

For instance, PLA plastic should be printed at temperatures between 190-220°C (374-428°F) while ABS plastic needs to be printed at temperatures between 220-250°C (428-482°F). Extreme cold or hot temperatures can also lead to filament breaking off during printing and other problems such as clogs, irregular layers, and inconsistent extrusion. Therefore, it’s important to keep the 3D printer within the recommended temperature range in order to produce high-quality prints every time.

Impact on Print Quality

Room temperature plays a significant role in the quality of 3D prints. If the ambient temperature is too low, then the plastic filament may become brittle and break off during printing. This can lead to clogs, irregular layers, and inconsistent extrusion. On the other hand, if the temperature is too high, then warping and deformation of parts can occur. In order to produce high-quality prints every time, it’s important to keep the 3D printer within the recommended range of 20-30°C (68-86°F).

It’s also important to consider the material being used since some materials require higher temperatures than others in order to achieve successful prints. By keeping the room temperature under control and making sure that your 3D printer is calibrated correctly for your material, you can ensure that you will get consistent results with every print.

Effects on Warping Issues

Warping is one of the most common issues with 3D printing, and it can be caused by a number of factors. Room temperature is an often overlooked culprit, as extreme temperatures can cause parts to warp during printing. Warping occurs when two sides of the object cool at different rates due to unequal airflows or temperature variations within the 3D printer’s chamber.

To reduce warping issues, it’s important to make sure that your 3D printer is in a room that has a stable temperature range between 20-30°C (68-86°F). Additionally, some materials are more prone to warping than others, so be sure to take this into consideration when choosing filament for your prints. By keeping the room temperature consistent and selecting the right filament for your project, you can ensure that your prints will turn out straight and true every time.

Necessity for Constant Temperature Setting

Maintaining a consistent temperature setting for 3D printing is essential for successful prints. An ideal temperature range for 3D printing is between 20-30°C (68-86°F). Straying from this range can cause warping, which is one of the most common issues with 3D printing. Warping occurs when two sides of the object cool at different rates due to unequal airflows or temperature variations within the 3D printer’s chamber.

To ensure that your prints come out straight and true every time, it’s important to keep the room temperature within the recommended range. Additionally, some materials are more prone to warping than others, so selecting a filament that won’t warp under certain temperatures is also key. By following these simple steps, you can ensure that your 3D prints will be successful every time.

Benefits of Heated Enclosure and Bed Temperatures

Heated enclosures and beds can be extremely beneficial for 3D printing. They help to reduce warping, which can be a major issue when 3D printing. Heated enclosures help to maintain a consistent temperature within the printer’s chamber and help to keep the air flow even. They also help to evenly heat up the bed, which helps the filament stick better during the printing process.

This is especially helpful when working with materials that have a tendency to warp under specific temperatures, as it keeps those temperatures more consistent throughout the print. Finally, heated enclosures and beds provide an additional layer of safety by shielding users from any potential harm caused by high temperatures or hot surfaces. By using heated enclosures and beds, you can ensure that your prints come out straight and true every time!

Thermal Stress Considerations

When 3D printing, it is important to consider thermal stress. Thermal stress occurs when the temperature of a material changes quickly, often resulting in warping. Warping can cause the print to be inaccurate and can cause damage to the printer itself. To reduce the risk of this occurring, it is important to keep temperatures consistent throughout the printing process.

This can be achieved through using heated enclosures and beds as well as careful consideration of ambient temperatures and materials used. Additionally, it is important to use cooling fans on prints that require them in order to reduce thermal stress on certain parts of the print. By taking these precautions and monitoring temperatures carefully, users can avoid any potential issues caused by thermal stress.