What do you need to start resin 3d printing?

Have you been considering getting into resin 3D printing? Perhaps you’ve seen some of the incredible creations that can be made with this technology and are curious about how it all works. But before you dive in headfirst, there are a few things you need to know.

Resin 3D printing is a fascinating process that uses a liquid polymer that hardens when exposed to UV light to create highly-detailed objects. It’s a popular option among hobbyists and professionals alike, but getting started can be intimidating if you don’t know what you need.

This guide will walk you through the essential components required to start resin 3D printing. From the printer itself to the various tools and materials you will need, this article will provide a comprehensive overview to help you get started on your resin 3D printing journey. Whether you’re a complete beginner or a seasoned 3D printing veteran, this guide has everything you need to know to get started with resin 3D printing.

What do you need to start resin 3D printing?

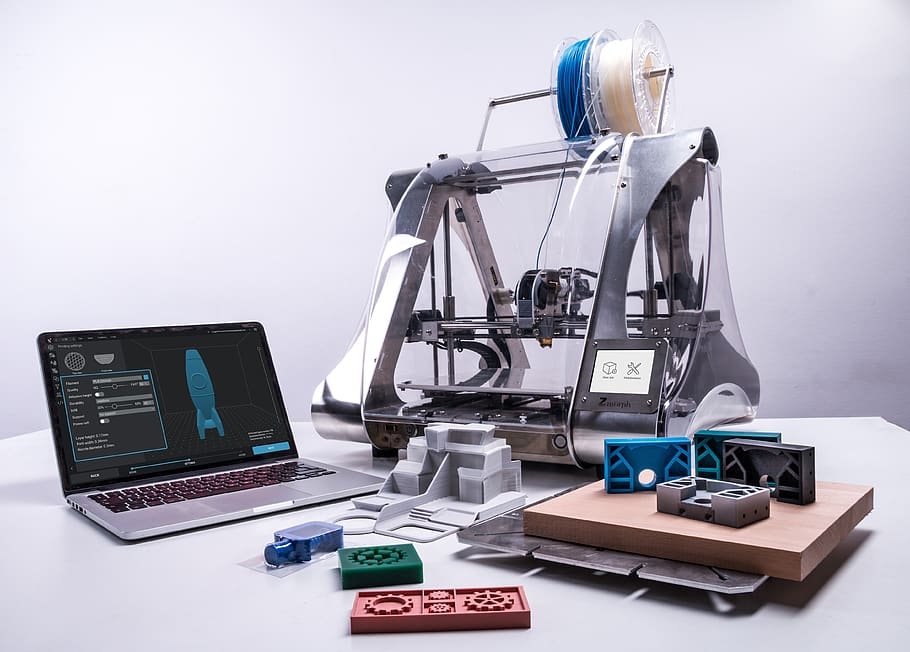

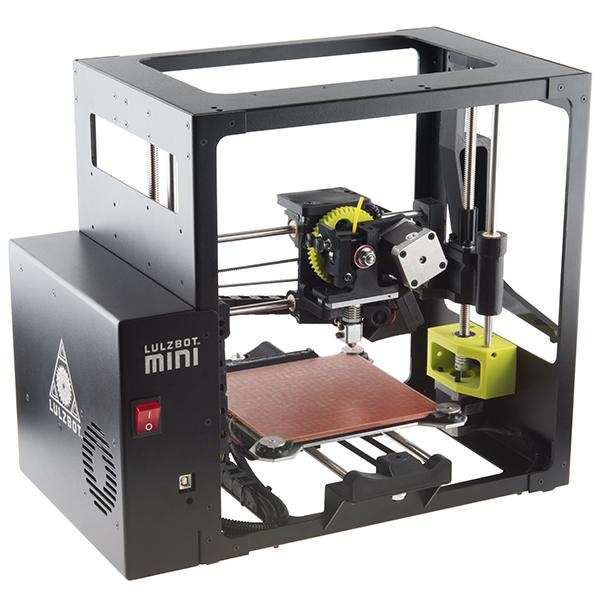

1. 3D Printer: The first component you’ll need for resin 3D printing is a 3D printer. This type of printer works by using light to harden liquid resin, creating a physical object from a digital model. It’s important to find the right 3D printer for your needs, as different models can have different capabilities and features.

2. Resin : The next component you’ll need is resin. This liquid polymer hardens when exposed to a UV light, allowing it to be used in 3D printing. Different types of resin can have different characteristics, such as different colors, viscosities, and curing times.

3. Build Platform: The build platform is the surface that your objects are printed on. It’s important to choose a platform that is stable and will not warp under the heat of the printer’s light source.

4. Supports: Supports are structures used to hold objects in place while they are being printed. They can be made from a variety of materials, including plastic, metal, or even resin itself.

5. Post-Processing Tools: After your object has been printed, you may need to use certain post-processing tools. These can include sanding and polishing tools, as well as other materials for finishing your object.

These are the essential components you’ll need to get started with resin 3D printing. With these components in hand, you’re now ready to begin creating your own amazing 3D prints!

Other resin 3D printing accessories

Resin 3D printing is becoming increasingly popular due to its precision, strength, and fine detail. To ease your experience with resin 3D printing, there are several accessories you should consider. Firstly, a paint scraper or a pallet knife can help remove the prints from the build plate easily and safely. Additionally, having dedicated paper towels can be very useful in case of any spills or excess resin. A toothbrush is essential for getting rid of any extra resins on the finished print, as it won’t damage the print’s details like other cleaning tools do.

Moreover, it’s highly recommended to have an FEP film that covers the build surface during sculpting and helps getting a better finish. For more advanced users who handle hazardous resins, safety filters need to be used too to remain safe when sanding and polishing their own projects. Being aware of such requirements will save you time and money in the long run when dealing with resin 3D printing. With all these items together in one set-up one can start off on this intriguing hobby easily and safely!

Paint scraper or pallet knife

When 3D printing a part, the last step is to remove it from the printer’s build plate—and that removal can be tricky. Newly printed models are usually quite delicate, and thus require extra care when extracting them from their chassis. That’s why experts recommend reaching for a wider tool like a paint scraper or pallet knife.

Since these tools are wider in size than your standard kitchen or utility knife, they provide more support and less stress against the plastic material of the 3D part as you pry it off the build plate. Furthermore, paint scrapers are made of stiff yet flexible metals that flex ever so slightly with each sweep, ensuring a gentle first impression with your jazzy new model. Pallet knives also have slightly rounded edges which help prevent nicks and scratches on both your model and its surroundings. So if you’re looking for an easy way out when removing parts from your 3D printer after printing say no more; grab yourself a paint scraper or pallet knife!

Paper towel

Paper towels are an essential tool for any printing enthusiast due to their ability to absorb spills quickly and efficiently. Paper towels have a unique absorbency capacity that far surpasses other cleaning materials, making them ideal for containing resin-based messes. In order to minimize cost and waste, it is best to purchase paper towels in bulk now, because once resin messes occur they can cause irreversible staining unless cleaned systematically.

When it comes to selecting the right paper towel for this task, it is important to understand that not all kinds are created equal. Pantry towels tend be more highly absorbent than those found in drugstores, so if you wish to maintain the highest level of cleanliness and prevention of staining you should seek out these types instead. Additionally, since this task involves wiping down resins there may be an added benefit from using disposable disinfectant wipes between rounds of paper towels. This can help target any stubborn spots that could potentially stain the workspace even further.

Toothbrush

Using a toothbrush for resin 3D printing is essential. It allows you to quickly and easily remove excess resins after a print is completed. This ensures that your prints look like they were printed right off the printer. A toothbrush also works great for brushing away dust or any other particles that were left behind after sanding a part. Make sure that you purchase a toothbrush with soft bristles though, as hard bristles may cause undue damage to your 3D prints.

Having a dedicated brush also helps to keep your 3D environment neat and tidy by limiting the amount of cross-contamination from one type of material to another. If there are visible pieces of plastic or metal filament on the brush, it is important to throw it away and start with a new one before beginning the next project. Additionally, better cleaning materials such as isopropyl alcohol can be used in conjunction with the toothbrush for optimal results. With the proper tools and practices in place, having success when printing in resin is much easier!

Filter

Using filters during the 3D printing process is a great way to reduce waste and save resin. Specifically, filter out any residual cured resins which have been left behind in the vat after a completed print job. There are two main options when it comes to filters for 3D printing: permanent and disposable. Permanent filters can be more economical over time although they need to be washed after each use. Disposable filters are convenient and ready to use with each new batch of resin but require more frequent replacement depending on how frequently you print.

Both options of filter can help keep your prints from becoming marred or damaged from foreign particles that can get into the vat if it isn’t properly cleaned or filtered between uses. This ultimately comes down to personal preference as well as the budget for your printer and its accessories. Ultimately, however, having effective filtration is essential for ensuring smooth prints that are free of blemishes caused by debris left in the vat between uses.

FEP film

FEP film is an indispensable part of resin 3D printing. It is a transparent, double-layered foil that can be inserted into the tank linked to the 3D printer. This film creates a clear pathway for ultraviolet radiation to harden the resin while printing is still ongoing. This makes the entire 3D printing process faster, reducing wait time and improving productivity.

Using FEP film prevents damage to the model’s strength or accuracy since it creates such a precise and constant heat source for curing resins during printing. In addition, FEP Film also helps to reduce post processing time by providing a smoother finish on parts as they come out of the printer. With this level of detail, you can have confidence in your version ofthe model as well as quick production time scales. Overall, FEP Films are unbeatable when it comes to getting top quality prints with excellent speed and accuracy.

How long does Resin printing take?

3D resin printing is a popular and widely used 3D printing technology that offers superior results over filament-based printers. However, the main question often asked by many first-time users is how long does it take for their objects to be printed? The answer to this question can vary widely, from as little as 30 minutes or could even take up to one week or more.

Factors such as the size and complexity of the model, plus the desired print resolution, all play a significant role in determining how long 3D resin printing will take. Furthermore, the type of printer you are using also affects this time frame greatly. SLA resin printers are quite popular options for highly detailed prints, however they usually come with a higher cost but also boast faster turnaround times compared to other types of 3D printers. In terms of bang-for-buck models there could be cheaper options which could bring down your outlay yet still deliver good quality prints. Ultimately however, high end printers tend to have shorter waiting periods and therefore may be best suited if you’re tight on timeframes.