Are 3d printer nozzles universal?

If you’re new to the world of 3D printing, you might be wondering if all 3D printer nozzles are universal. After all, it would be convenient if you could easily switch out nozzles between different machines or brands, right?

The 3D printing industry has experienced massive growth in the past few years, with more and more people buying their own 3D printers for personal use. As a result, there are now numerous brands and models on the market, each with their own unique features and specifications.

One of the most important aspects of 3D printing is the nozzle, which is responsible for dispensing the melted filament that forms the object. But are 3D printer nozzles universal? The answer is not a simple one, as there are several factors to consider. In this article, we’ll explore the various types of nozzles available and whether or not they can be used across different machines or brands.

What are 3D Printer Nozzles?

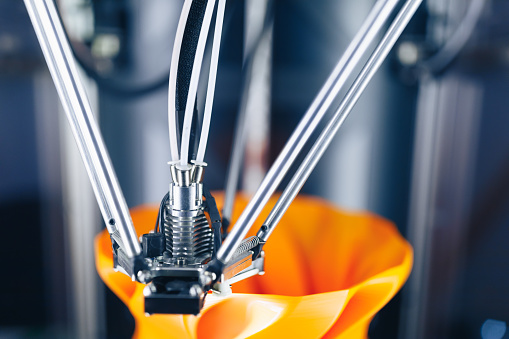

3D printer nozzles are small, cylindrical attachments that are used to create models from liquid plastic. They are typically attached to the end of an extruder arm and work by heating the plastic until it is molten then pushing it through a tiny hole in the nozzle. This produces a thin stream of melted plastic that can be used to create complex objects.

Nozzles come in a variety of sizes, shapes, materials, and even colors and each type has its own advantages and disadvantages. Generally speaking, nozzles can be universal when it comes to different 3D printers as long as they are compatible with the specific type of extruder being used. In some cases, you may need to purchase additional parts in order to use the nozzle with your 3D printer.

Why Do We Need 3D Printer Nozzles?

3D printer nozzles are a necessity for anyone who wants to create 3D objects from liquid plastic. Without the nozzle, it would be impossible to precisely control the flow of plastic and achieve the desired results. Nozzles come in a variety of sizes and shapes, allowing you to adjust the stream of plastic to best fit your project.

They also come in different materials, such as brass or stainless steel, which can affect how quickly they heat up and how easy they are to clean. The right nozzle size and shape can help you achieve intricate detail on your model while reducing waste and ensuring accuracy. Additionally, nozzles with different colors can add an extra layer of creativity to your 3D printing projects. In short, 3D printer nozzles are an essential tool for any maker looking to produce high-quality prints.

Types of 3D Printer Nozzles

There are several different types of 3D printer nozzles available on the market. Each type has its own unique advantages, making it important to choose the right one for your needs. Brass nozzles are known for their durability and heat retention, while stainless steel nozzles offer a more precise output.

For finer detail work, there are even smaller nozzles designed specifically for intricate 3D printing projects. For larger prints, you may want to consider a nozzle with a wider diameter that can produce thicker layers of plastic more quickly. Depending on the type of filament you’re using, certain nozzle sizes will be better suited for your project than others. Ultimately, the correct nozzle can help you achieve smoother and higher-quality results when creating 3D objects from liquid plastic.

Stainless Steel Nozzle

Stainless Steel Nozzles are a popular choice for 3D printing due to their durability, precision, and heat retention. These nozzles are made of steel alloy which is highly resistant to corrosion and can withstand high temperatures. The rounds shape of a stainless steel nozzle allows for smoother and more precise extrusion of molten plastic filament.

This makes it ideal for fine detail work such as creating intricate shapes or small objects with complex curves. Stainless steel nozzles also offer better heat distribution than brass or plastic nozzles, ensuring that your prints will be consistent with little to no warping. With proper maintenance, these nozzles can produce beautiful prints time after time without any problems.

Brass Nozzle

Brass Nozzles are a great choice for 3D printing due to their affordability and good thermal conductivity. Brass is a strong, malleable metal which is highly resistant to corrosion and can withstand high temperatures. The rounded shape of a brass nozzle allows for smoother extrusion of molten plastic filament, making it suitable for forming basic shapes or objects with minimal detail work.

Brass also has excellent heat retention properties, which helps prevent warping in your prints. Because they are cost-effective and easy to use, brass nozzles are popular among both hobbyists and professionals alike. With proper maintenance, these nozzles can provide reliable performance each time you print.

Other Materials Used for 3D Printer Nozzles

In addition to brass, other materials are used for 3D printer nozzles, including stainless steel, hardened steel, and even ruby. Stainless steel nozzles are corrosion-resistant and able to withstand temperatures of up to 500°C. Hardened steel nozzles are the most durable option available, offering excellent wear resistance against abrasive materials like glass fiber or carbon fiber reinforced plastics.

Ruby nozzles have a much higher abrasion resistance than brass or stainless steel nozzles and can handle temperatures up to 700°C. No matter what type of nozzle you choose, it’s important to regularly clean your nozzle tip in order to maintain optimal performance. Keeping your nozzle tip clean will also help prevent jams and clogs during printing and ensure that your prints come out looking great every time.

Installation and Maintenance of 3D Printer Nozzles

The installation and maintenance of 3D printer nozzles are an important part of successful 3D printing. Properly installing a nozzle ensures that it will perform optimally and last for a long time. The first step is to ensure that the nozzle is compatible with the 3D printer model, as some models require specific nozzles. It’s also important to make sure the nozzle has been properly cleaned before installation, as any dust or debris can interfere with printing performance.

Once the nozzle has been installed, it must be correctly aligned in order to produce accurate results. Finally, it’s advisable to regularly inspect and clean the nozzle to prevent obstructions from occurring during use. With proper installation and regular maintenance, a 3D printer nozzle can provide reliable performance for many years.

Preparing the Heater Block for a New Nozzle

Changing a 3D printer nozzle requires proper preparation of the heater block. This involves removing the existing nozzle and cleaning the block to ensure it is free of any dust or debris. It is important to use a heat-resistant glove when handling the hot components, as well as an appropriate tool for unscrewing the nozzle.

After all of the pieces have been removed and cleaned, any additional modifications must be completed before installing a new nozzle. This includes making sure that all threads are properly aligned and that any o-rings or seals fit securely in place. Preparing the heater block correctly will help ensure that a new nozzle is installed and performs accurately.

Cleaning the Old/Used Nozzle Before Installing a New One

When replacing a 3D printer nozzle, it is important to remove and clean the old nozzle before installing the new one. This will help ensure that the new nozzle performs optimally and does not become clogged or contaminated by residual build-up from the previous nozzle.

The cleaning process should be done with a soft cloth and an appropriate solvent, such as isopropyl alcohol. It is important to thoroughly clean all areas of the nozzle, including the tip and any internal channels. Once finished, make sure to dry off the nozzle before reinstalling to prevent any potential corrosion or damage caused by moisture. Cleaning an old nozzle properly will also help extend its lifespan if it needs to be re-used in the future.

Tips on Selecting the Correct Type and Size of 3D Printer Nuzzles Choose the Right Material for Your Application Consider Layer Heights and Quality Prints Understand Filament Diameter Requirements

When selecting a 3D printer nozzle, it is important to take into account the type of material you will be printing with as well as the layer heights and quality prints you desire. Depending on the type of material you are working with, different sized nozzles may be required.

For instance, if printing with ABS plastic, a 0.4mm nozzle is typically recommended for best results. Layer height also plays an important role in determining which nozzle size to use; lower layer heights require smaller nozzles for improved detail and accuracy. Additionally, filament diameter should be taken into consideration when choosing a nozzle; most printers are designed to work with 1.75mm or 3mm filaments but some specialty printers may require other sizes.

Finally, ensure that your chosen nozzle is compatible with your 3D printer before purchasing to avoid any potential issues down the line.

Conclusion

In conclusion, choosing the right 3D printer nozzle can make all the difference in getting the desired results from your prints. Factors such as material type, layer height, and filament diameter should be taken into account when selecting a nozzle size. Additionally, it is important to ensure that your chosen nozzle is compatible with your 3D printer. With careful consideration of these factors, you can easily find the perfect nozzle for your 3D printing needs.