Jasa 3d printing

Have you ever wondered how 3D printing works? Or maybe you’re interested in getting a 3D model printed for a project you’re working on? Look no further than jasa 3D printing!

3D printing has revolutionized the way we look at manufacturing and production. What used to take months can now be done in a matter of hours. And with more and more industries embracing this technology, 3D printing services are becoming increasingly accessible.

But with so many jasa 3D printing companies out there, it can be overwhelming to choose the right one for your needs. In this article, we’ll take a closer look at what jasa 3D printing is, how it works, and what to consider when choosing a provider. Whether you’re a business owner or a hobbyist, this guide will help you navigate the world of 3D printing and find the perfect jasa for your project.

What is 3D printing?

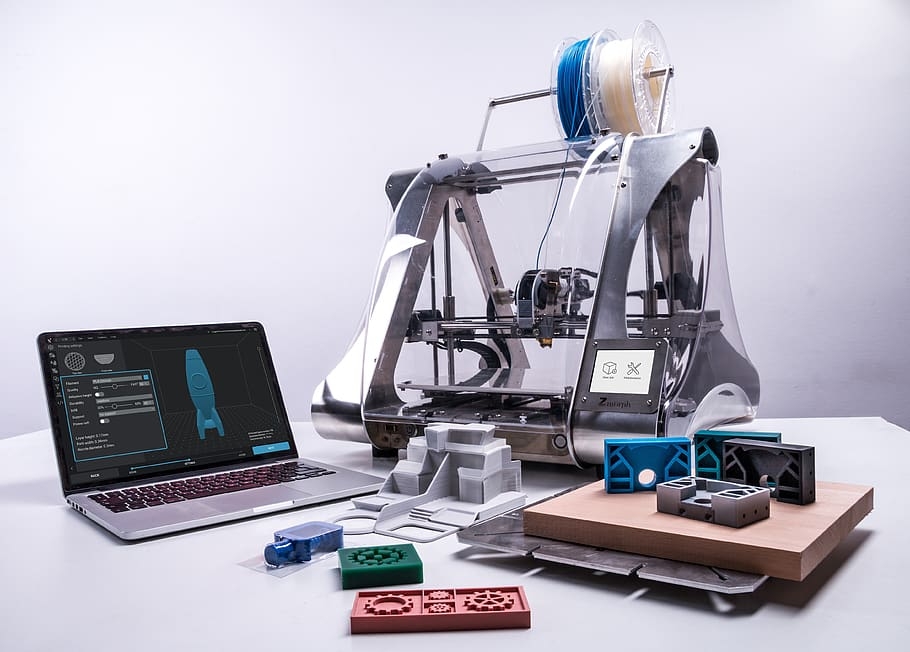

3D printing or additive manufacturing is a process of making three-dimensional solid objects from a digital file. This fabrication process creates three-dimensional parts layer by layer from various materials such as plastic, rubber, glass, and metal. It has revolutionized the production process since traditional methods could not create complicated shapes with intricate features or small spaces between them.

Two popular 3D printing technologies are Multi Jet Fusion (MJF) and selective laser sintering (SLS). MJF uses inkjet printheads to deposit a powdered material followed by heating and pressing to fuse it into an object. Meanwhile, SLS technology uses lasers to melt the material in thin layers onto the build platform. The process of choosing the most suitable manufacturing technology for your application depends on factors such as shape complexity, material choice, and cost or time saved through automation. Compared to injection molding processes or other traditional methods of production such as milling, 3D printing offers fast turnarounds at lower tooling costs and offers more freedom with design complexities that could be difficult or impossible to produce any other way.

Jasa 3D printing

is a method of manufacturing where objects are created layer by layer. This process is done using either a computer-aided design (CAD) file or other digital 3D model. The 3D printer reads the digital model and creates a physical object from it, usually made out of plastic, metal, resin, or other materials.

When it comes to jasa 3D printing services, there are a few different options to consider. Some services offer printing on demand, where you can upload your own digital model and have it printed quickly and easily. Other services provide a full package of design, prototyping, and manufacturing services. This could include 3D scanning, CAD modeling, rapid prototyping, and mass production.

When choosing a jasa 3D printing provider, it ‘s important to consider the quality of their work, turnaround time, and cost. It’s also important to make sure they have experience with your chosen material and are knowledgeable about the latest 3D printing technology.

No matter what your needs are, there is a jasa 3D printing company out there that can help you get the job done. With 3D printing technology advancing at such an incredible rate, the possibilities are endless. So don’t hesitate to explore your options and get started on your next project today!

How to use multi jet fusion for functional 3D-printed parts?

Multi Jet Fusion is a form of additive manufacturing technology developed by HP that makes use of fusing and detailing agents to create 3D-printed parts with ultra-fine precision. With Multi Jet Fusion, it’s possible to produce functional, lightweight parts without relying on traditional manufacturing methods such as injection molding or machining. The process allows for rapid prototyping and production of parts with high precision and durability. It also offers a great deal of design flexibility as parts can be customized to fit specific needs and requirements.

Using Multi Jet Fusion for functional 3D-printed part production is an ideal solution for reducing lead time in product development processes, increasing consistency in the production batch, and achieving better accuracy than could traditionally be achieved with subtractive techniques. Its advanced features make it ideal for the manufacture of components that require intricate details or tight tolerances, such as medical appliances, electronics housings, prototype models, and more. With the ability to print complex geometries not previously possible with traditional manufacturing technologies coupled with its low cost material inputs, Multi Jet Fusion has revolutionized many industries by allowing them to achieve faster turnaround times while still maintaining top quality 3D printed parts.

One of the key benefits that Multi Jet Fusion offers is its ability to save time and money, while creating parts of superior quality. By utilizing this technology, many manufacturers are able to produce parts quicker and with higher accuracy than would be possible using traditional fabrication methods. In addition, the cost savings associated with 3D printing in general as compared to traditional fabrication methods can be significant. With its advanced features, Multi Jet Fusion is quickly becoming the go-to 3D printing technology for many industries due to its cost and time efficiency.

In order to achieve the best results with Multi Jet Fusion, it is important to consider the specific characteristics of your project and choose a material that matches its requirements. Different materials offer different advantages in terms of strength and flexibility, so selecting the right material is essential for achieving an optimal outcome. Additionally, understanding which features are critical to success will help inform decisions related to printer settings and post-processing techniques, ensuring the best possible performance for your finished product.