3d printing weight calculator.

Are you tired of guessing the weight of your 3D printed objects? Have you ever wondered how much filament you need for a specific project? It’s time to stop the guesswork and start using a 3D printing weight calculator.

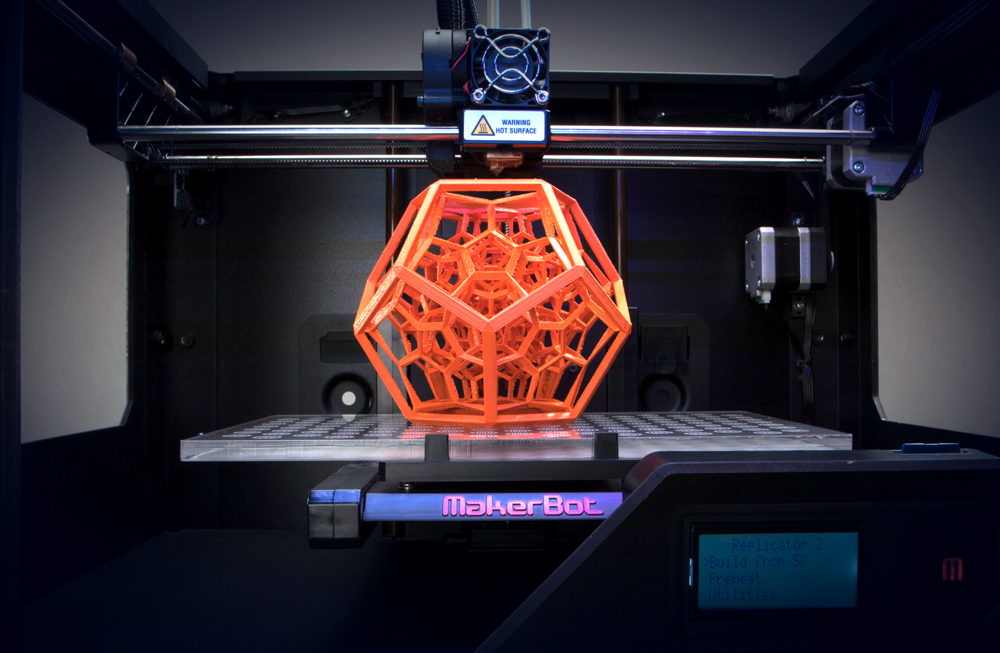

3D printing has become a popular hobby, with thousands of objects being created every day using various printers and materials. However, knowing the weight of your objects is essential if you want to print accurately and avoid wasting materials.

Fortunately, a 3D printing weight calculator can make this task much more manageable. If you’re new to 3D printing, calculating the weight of your objects may seem daunting. But with a few simple inputs and the use of this calculator, you can easily determine the weight of your 3D printed objects and the amount of filament you need to use. In this article, we will walk you through the steps to use this calculator and how it can help you achieve perfect 3D prints every time.

What is a Weight Calculator?

A weight calculator is a tool used to determine the weight of 3D printed objects. These calculators take into account the type of material used, as well as the size and shape of the object. By inputting these variables, users can quickly determine how much their 3D printed object will weigh in grams or kilograms. Weight calculators are useful for creating accurate models that meet specific design requirements such as strength, stability and durability.

They are also helpful for ensuring that your product meets any shipping regulations or restrictions. Weight calculators can be used for both prototyping and production purposes, allowing you to quickly adjust material types and sizes until you find the optimal design solution.

Advantages of Using a Weight Calculator

Using a weight calculator for 3D printing can provide numerous advantages. Weight calculators allow users to quickly determine the exact weight of their 3D printed object, ensuring that it meets any shipping regulations or restrictions. Additionally, they are useful for creating accurate models that meet specific design requirements such as strength, stability and durability.

Weight calculators can also save time and money, as they allow users to adjust material types and sizes until they find the optimal design solution without wasting resources on unnecessary prototypes or production runs. Furthermore, by accurately calculating the weight of an object before it is printed, users can be sure that their 3D printer is operating safely and efficiently. In short, using a weight calculator for 3D printing can help save time, money and resources while producing accurate models that meet all necessary requirements.

Efficiency and Precision

Using a weight calculator for 3D printing can be an invaluable tool to ensure efficiency and precision in the design process. By accurately calculating the weight of an object before it is printed, users can save time and money by reducing the need for unnecessary prototypes or production runs. Furthermore, a weight calculator allows users to optimize their design parameters by adjusting material types and sizes until they find the ideal balance between strength, stability and durability.

Additionally, accounting for weight during the design process will help ensure that 3D printers are operating safely and efficiently. In short, utilizing a weight calculator for 3D printing is an effective way to achieve greater efficiency and precision in both design and production processes.

Reduces Material Waste

Reducing material waste is an important consideration for any 3D printing project. A weight calculator can help users to minimize the amount of excess material used in their designs by providing accurate estimates for the amount of material needed for each part. This allows users to save money and resources, as well as reduce their environmental footprint by ensuring that only the necessary materials are used in their projects.

Additionally, a weight calculator can be used to optimize the size and shape of parts to ensure that they are as efficient as possible – reducing material wastage while still maintaining structural integrity. By utilizing a weight calculator, 3D printing users can ensure that they are using their resources responsibly, while also saving time and money in the process.

Saves Time

Using a weight calculator for 3D printing projects can help users save time by providing accurate estimates of the amount of material needed for each part. This allows users to avoid wasting time on trial and error designs that may not meet their requirements, as they can quickly determine the exact amount of material required. With this information in hand, users can begin their projects with confidence, knowing that they have calculated the right amount of materials before starting.

Additionally, a weight calculator can be used to optimize components to ensure that they are as efficient as possible – reducing build times while still maintaining structural integrity. By utilizing a weight calculator, 3D printing users can save time while also ensuring that their resources are being used responsibly.

Disadvantages of Using a Weight Calculator

Inaccurate Estimates

Using a weight calculator for 3D printing projects can be unreliable, as the estimates that it provides are based on assumptions made by the user. For example, the calculator might assume that all parts are created with uniform thickness or that certain types of material will be used for each component. If these assumptions are incorrect, then the results of the calculation may be inaccurate, resulting in an excess of materials being used (or not enough).

Furthermore, any inaccuracies in measurements when entering data into the calculator can lead to further discrepancies in the final estimate. As such, users should take extra caution to ensure that their inputs are accurate when using a weight calculator and consider alternative methods if they are unsure of their results.

Cost Implications

Using a weight calculator for 3D printing projects can have implications for cost. As the estimates provided by such calculators are based on assumptions, any inaccuracies can lead to an excess of materials being used (or not enough). This can result in higher costs associated with the project as more materials may need to be purchased or wasted if the inputs were incorrect.

Additionally, if measurements were inaccurate when entering data into the calculator, it could also lead to higher costs due to needing to redo parts of the project. Thus, it is important that users exercise caution when using a weight calculator and consider alternative methods if they are uncertain of their results.

Accuracy Issues

When using a weight calculator for 3D printing projects, it is important to be aware of the accuracy issues that can arise. Since calculators rely on certain assumptions, any inaccuracies in the measurements or specifications entered into them can lead to incorrect results.

This can mean that the user ends up with either too much material (leading to wasted resources) or not enough, requiring additional purchases. Additionally, if errors are made when entering data into the calculator, it could lead to costly delays and rework as parts of the project need to be redone. Therefore, it is important to make sure all inputs are accurate before relying heavily on a weight calculator’s results.

Complexity of Use

The complexity of use for 3D printing weight calculators can vary greatly depending on the specific model and its intended purpose. Some calculators are designed to be user friendly and straightforward, while others are more complex with a variety of settings and options that need to be adjusted in order to get accurate results. Those who are unfamiliar with the process may find it difficult to understand the different parameters, which could lead to inaccurate calculations.

As such, it is important for users to take time to thoroughly read any instructions or tutorials associated with the calculator before using it. Additionally, some calculators come with built-in features such as automatic error detection and correction that can help reduce errors, making them easier to use overall.

Finding the Right Weight Calculator for Your Needs

Finding the right weight calculator for your 3D printing needs can be difficult. There are a variety of calculators available, each with different features and capabilities. To find the best one for your needs, consider the complexity of use, accuracy, and any additional features it may offer. For instance, some calculators come with built-in automatic error detection and correction that can help reduce errors, making them easier to use overall.

Additionally, look for calculators that are designed with user-friendly interfaces and tutorials to make understanding the parameters simpler. Finally, compare prices between different models to ensure you’re getting the best value for your money. With a little research and consideration of your specific requirements, you should be able to find the perfect weight calculator for your 3D printing needs.